1月 . 20, 2025 11:19

Back to list

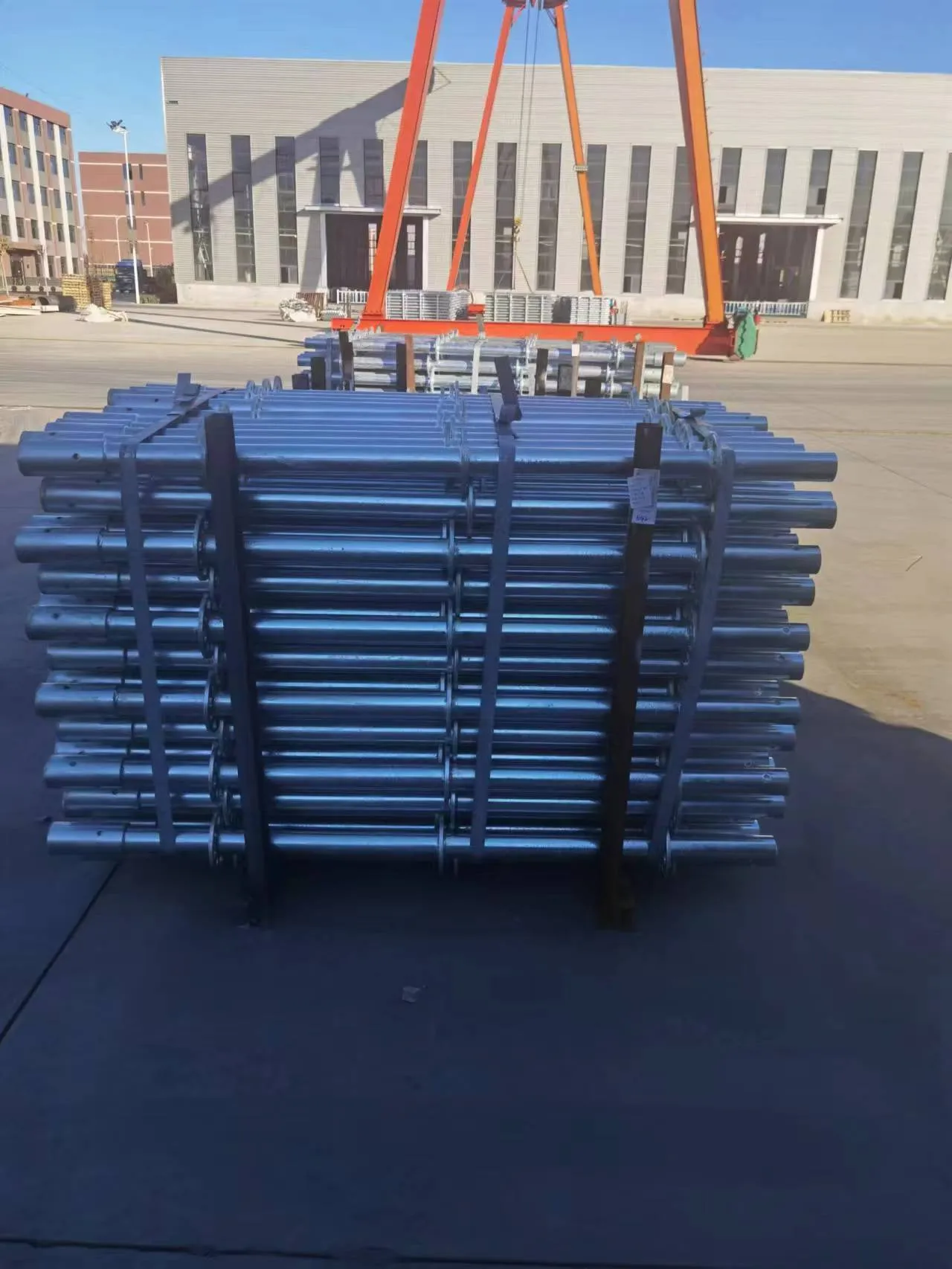

cover reinforcement

Reinforced concrete slabs stand as the backbone of modern construction, widely utilized for their strength and durability in both residential and commercial structures. The top reinforcement within a slab plays a critical role in ensuring the structural integrity and longevity of a building. Understanding its function, specifications, and relevance in current construction practices is essential for engineers, architects, and builders alike.

The expertise required for effectively designing and constructing slabs with top reinforcement involves comprehensive knowledge of both materials science and structural analysis. It necessitates an understanding of the behavior of concrete in different scenarios and the capability to predict potential stress points. Here, advanced modeling software aids in simulating different conditions, allowing engineers to design structures that are both efficient and economical. Authoritativeness in the realm of slab reinforcement comes from adhering to industry standards and building codes. These guidelines are established by professional bodies such as the American Concrete Institute (ACI) and British Standards Institution (BSI), which base their recommendations on extensive research and field data. Compliance assures both regulatory approval and safety guarantees. Finally, the trustworthiness of a construction firm or an architect lies in transparent communication and verifiable track records. Providing detailed documentation of the materials used, calculations conducted, and the construction process can elevate a client’s confidence. Additionally, regular inspections and maintenance, as part of the slab's lifecycle management, ensure ongoing trust and demonstrate a firm’s commitment to quality and safety. In conclusion, the importance of top reinforcement in slabs cannot be overstated. It is a cornerstone of modern construction that demands a nuanced understanding and a meticulous approach to implementation. By harnessing cutting-edge materials, adhering to established guidelines, and maintaining transparency, construction professionals can confidently assure durability and safety, meeting and exceeding client expectations.

The expertise required for effectively designing and constructing slabs with top reinforcement involves comprehensive knowledge of both materials science and structural analysis. It necessitates an understanding of the behavior of concrete in different scenarios and the capability to predict potential stress points. Here, advanced modeling software aids in simulating different conditions, allowing engineers to design structures that are both efficient and economical. Authoritativeness in the realm of slab reinforcement comes from adhering to industry standards and building codes. These guidelines are established by professional bodies such as the American Concrete Institute (ACI) and British Standards Institution (BSI), which base their recommendations on extensive research and field data. Compliance assures both regulatory approval and safety guarantees. Finally, the trustworthiness of a construction firm or an architect lies in transparent communication and verifiable track records. Providing detailed documentation of the materials used, calculations conducted, and the construction process can elevate a client’s confidence. Additionally, regular inspections and maintenance, as part of the slab's lifecycle management, ensure ongoing trust and demonstrate a firm’s commitment to quality and safety. In conclusion, the importance of top reinforcement in slabs cannot be overstated. It is a cornerstone of modern construction that demands a nuanced understanding and a meticulous approach to implementation. By harnessing cutting-edge materials, adhering to established guidelines, and maintaining transparency, construction professionals can confidently assure durability and safety, meeting and exceeding client expectations.

Share

Next:

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products