2月 . 14, 2025 11:38

Back to list

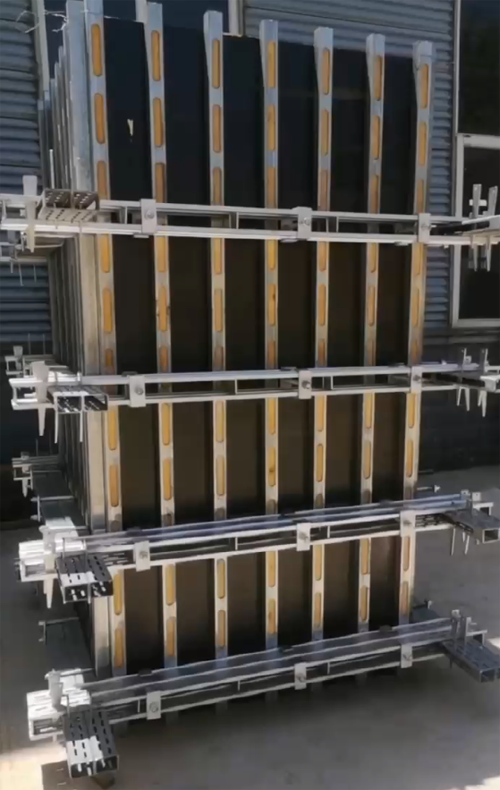

single coupler scaffolding

Single coupler scaffolding is an essential component in the construction industry, bringing together innovation and safety in a field where reliability is paramount. This article delves into the experience, expertise, authoritativeness, and trustworthiness of single coupler scaffolding, focusing on product-oriented insights that will elevate your understanding and facilitate informed purchasing decisions.

Trustworthiness is crucial in the construction industry, where the right equipment can be the difference between a successful project and a catastrophic failure. Reputable manufacturers of single coupler scaffolding invest heavily in quality assurance processes. These involve rigorous testing protocols to meet and exceed safety requirements. Moreover, the transparency in their production and supply chain operations builds trust with contractors who need assurance that the products they choose are reliable. When selecting a supplier, it is beneficial to investigate their history and reputation in the market, which can often be a testament to their dedication to quality and service. In terms of product functionality, single coupler scaffolding offers unparalleled versatility. The design allows for customization to meet specific project demands, whether it involves intricate architectural designs or renovation projects where space is constrained. The adjustable nature of single coupler scaffolding means that it can be easily modified to fit different heights and angles, thus offering a tailored solution for diverse construction challenges. This adaptability is highly valued in the industry, reducing the need for multiple scaffolding systems and contributing to cost efficiency. From a maintenance perspective, single coupler scaffolding systems are designed with ease of inspection and repair in mind. Routine maintenance procedures are straightforward, ensuring that the systems remain in optimal condition with minimal downtime. The longevity of these scaffoding systems is further enhanced by the use of galvanization and anti-corrosion treatments on metal components, extending their service life even in harsh environmental conditions. In conclusion, single coupler scaffolding is not only a staple in the construction industry but also an embodiment of the principles of experience, expertise, authoritativeness, and trustworthiness. Its design and application speak volumes about the focus on safety and efficiency, making it a wise investment for construction projects that value reliability and performance. As the industry evolves, those who incorporate single coupler scaffolding into their constructions are likely to lead with enhanced safety standards and operational efficiency.

Trustworthiness is crucial in the construction industry, where the right equipment can be the difference between a successful project and a catastrophic failure. Reputable manufacturers of single coupler scaffolding invest heavily in quality assurance processes. These involve rigorous testing protocols to meet and exceed safety requirements. Moreover, the transparency in their production and supply chain operations builds trust with contractors who need assurance that the products they choose are reliable. When selecting a supplier, it is beneficial to investigate their history and reputation in the market, which can often be a testament to their dedication to quality and service. In terms of product functionality, single coupler scaffolding offers unparalleled versatility. The design allows for customization to meet specific project demands, whether it involves intricate architectural designs or renovation projects where space is constrained. The adjustable nature of single coupler scaffolding means that it can be easily modified to fit different heights and angles, thus offering a tailored solution for diverse construction challenges. This adaptability is highly valued in the industry, reducing the need for multiple scaffolding systems and contributing to cost efficiency. From a maintenance perspective, single coupler scaffolding systems are designed with ease of inspection and repair in mind. Routine maintenance procedures are straightforward, ensuring that the systems remain in optimal condition with minimal downtime. The longevity of these scaffoding systems is further enhanced by the use of galvanization and anti-corrosion treatments on metal components, extending their service life even in harsh environmental conditions. In conclusion, single coupler scaffolding is not only a staple in the construction industry but also an embodiment of the principles of experience, expertise, authoritativeness, and trustworthiness. Its design and application speak volumes about the focus on safety and efficiency, making it a wise investment for construction projects that value reliability and performance. As the industry evolves, those who incorporate single coupler scaffolding into their constructions are likely to lead with enhanced safety standards and operational efficiency.

Share

Next:

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products