2月 . 17, 2025 23:49

Back to list

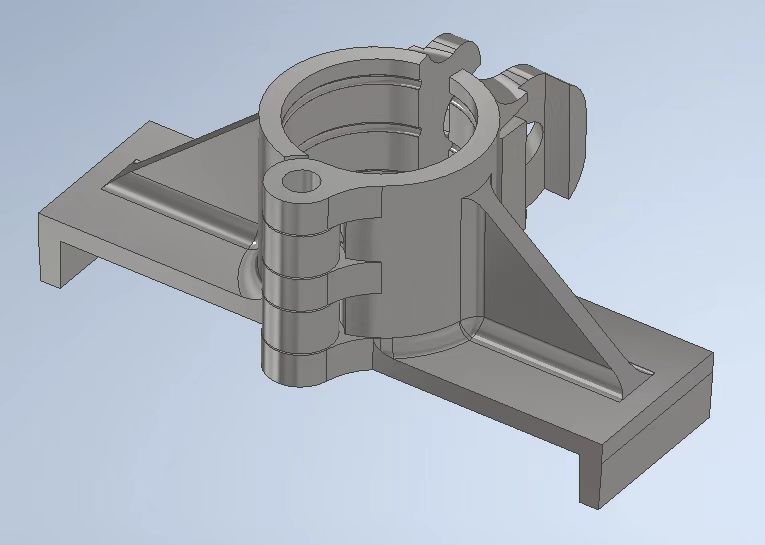

Scaffolding

Scaffold couplers are indispensable devices in the construction industry, designed to connect and secure scaffold tubes to ensure safety and stability in scaffolding systems. Understanding the various types of scaffold couplers is critical for selecting the right product for specific applications, which directly influences the safety and efficiency of construction projects.

Lastly, ladder couplers are specifically designed for attaching ladders to scaffolding structures, helping to maintain a safe, consistent, and secure vertical access alongside scaffolding sections. Proper use of ladder couplers can significantly reduce the risk of accidents associated with makeshift or unsecured ladder systems on-site. Typically constructed from durable and weather-resistant materials, ladder couplers ensure prolonged use even in adverse environmental conditions. Selecting high-quality scaffold couplers involves considering factors like construction material, load capacity, ease of installation, and compliance with safety standards. In the high-stakes realm of construction, quality and compatibility of scaffold couplers can affect not only project timelines but also the safety of workers operating hundreds of feet above ground. Ensuring your couplers are sourced from reputable manufacturers and meet industry safety certifications is crucial. These certifications guarantee that the couplers have undergone rigorous testing and meet the necessary structural integrity to support scaffolding frameworks safely. For this reason, many industry professionals rely on couplers that are certified to international standards such as BS EN 74 (for Europe) or OSHA standards (in the USA). The expertise required to choose the right type of scaffold coupler attracts experienced professionals who can ensure that every joint is secure, and every length of scaffolding is in place without risk of displacement. This requirement often means training and certification for those tasked with assembling scaffolding in varying environments. Beyond just the technical specifications, scaffold couplers are now also available with modern innovations such as lightweight materials that ease manual labor while maintaining heightened strength. The use of corrosion-resistant materials ensures the longevity and reliability of scaffold installations, even in challenging weather conditions. In summary, understanding the various scaffolding coupler types and their applications can empower project managers and construction workers with the confidence to implement safe, efficient, and compliant scaffolding systems. With the right couplers, scaffolding can be tailored effectively to the architectural and environmental demands of any construction site, promoting safety, structural integrity, and operational success.

Lastly, ladder couplers are specifically designed for attaching ladders to scaffolding structures, helping to maintain a safe, consistent, and secure vertical access alongside scaffolding sections. Proper use of ladder couplers can significantly reduce the risk of accidents associated with makeshift or unsecured ladder systems on-site. Typically constructed from durable and weather-resistant materials, ladder couplers ensure prolonged use even in adverse environmental conditions. Selecting high-quality scaffold couplers involves considering factors like construction material, load capacity, ease of installation, and compliance with safety standards. In the high-stakes realm of construction, quality and compatibility of scaffold couplers can affect not only project timelines but also the safety of workers operating hundreds of feet above ground. Ensuring your couplers are sourced from reputable manufacturers and meet industry safety certifications is crucial. These certifications guarantee that the couplers have undergone rigorous testing and meet the necessary structural integrity to support scaffolding frameworks safely. For this reason, many industry professionals rely on couplers that are certified to international standards such as BS EN 74 (for Europe) or OSHA standards (in the USA). The expertise required to choose the right type of scaffold coupler attracts experienced professionals who can ensure that every joint is secure, and every length of scaffolding is in place without risk of displacement. This requirement often means training and certification for those tasked with assembling scaffolding in varying environments. Beyond just the technical specifications, scaffold couplers are now also available with modern innovations such as lightweight materials that ease manual labor while maintaining heightened strength. The use of corrosion-resistant materials ensures the longevity and reliability of scaffold installations, even in challenging weather conditions. In summary, understanding the various scaffolding coupler types and their applications can empower project managers and construction workers with the confidence to implement safe, efficient, and compliant scaffolding systems. With the right couplers, scaffolding can be tailored effectively to the architectural and environmental demands of any construction site, promoting safety, structural integrity, and operational success.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products