1月 . 30, 2025 05:25

Back to list

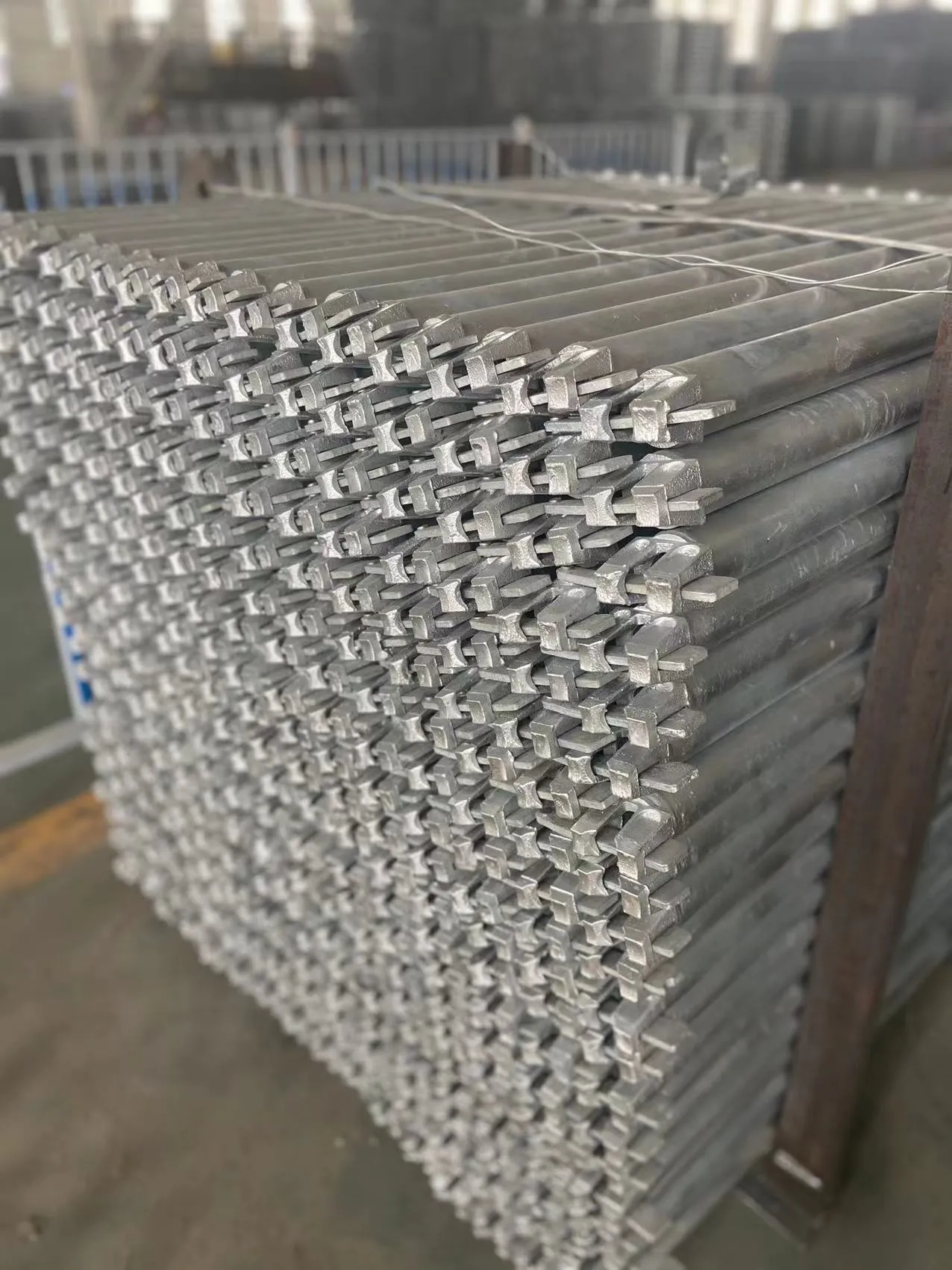

Scaffolding accessories

In the realm of construction, formwork plays an instrumental role in shaping concrete into the desired structures. It’s a temporary mold into which concrete is poured, supporting the concrete until it hardens and achieves sufficient strength to support itself. Understanding the intricacies of formwork and selecting the right type and material for a given project are crucial skills in construction management, ensuring that structures are not only virtually flawless but also economically viable.

Renowned construction experts advocate for meticulous planning and execution of formwork projects. The integration of modern technology such as 3D modeling and Building Information Modeling (BIM) allows for precision planning, reducing formwork waste and optimizing resource deployment. Combined with smart technologies, this digital approach can simulate construction scenarios, forecasting potential challenges and streamlining the entire process. Trustworthiness in formwork solutions is solidified through adherence to engineering standards and safety protocols. Safety is prioritized by ensuring that the formwork is correctly assembled and capable of bearing the required load through rigorous testing and compliance with statutory regulations. It's imperative to conduct regular inspections throughout the project lifecycle to prevent formwork failure, which can have catastrophic consequences. Formwork construction is not a monolithic field; rather, it requires a nuanced approach blending technical skills, foresight, and innovative thinking. The ever-evolving landscape demands staying abreast of emerging trends and technologies that enhance efficiency and effectiveness. Whether one opts for traditional or cutting-edge formwork materials, the emphasis remains on balancing cost, quality, and performance to meet the unique needs of each project. For those involved in construction projects, honing expertise in formwork can dramatically alter the trajectory of a project. It transforms potential deterrents into deliverables, ensuring structures meet their intended design with precision and stability. Implementing best practices in formwork construction not only ensures safety and compliance but also reinforces the integrity and longevity of the built environment. Through relentless pursuit of excellence, formwork becomes the blueprint for innovation in constructing the iconic edifices of tomorrow, rendering formwork more than mere molds but the foundational backbone of modern architecture and construction.

Renowned construction experts advocate for meticulous planning and execution of formwork projects. The integration of modern technology such as 3D modeling and Building Information Modeling (BIM) allows for precision planning, reducing formwork waste and optimizing resource deployment. Combined with smart technologies, this digital approach can simulate construction scenarios, forecasting potential challenges and streamlining the entire process. Trustworthiness in formwork solutions is solidified through adherence to engineering standards and safety protocols. Safety is prioritized by ensuring that the formwork is correctly assembled and capable of bearing the required load through rigorous testing and compliance with statutory regulations. It's imperative to conduct regular inspections throughout the project lifecycle to prevent formwork failure, which can have catastrophic consequences. Formwork construction is not a monolithic field; rather, it requires a nuanced approach blending technical skills, foresight, and innovative thinking. The ever-evolving landscape demands staying abreast of emerging trends and technologies that enhance efficiency and effectiveness. Whether one opts for traditional or cutting-edge formwork materials, the emphasis remains on balancing cost, quality, and performance to meet the unique needs of each project. For those involved in construction projects, honing expertise in formwork can dramatically alter the trajectory of a project. It transforms potential deterrents into deliverables, ensuring structures meet their intended design with precision and stability. Implementing best practices in formwork construction not only ensures safety and compliance but also reinforces the integrity and longevity of the built environment. Through relentless pursuit of excellence, formwork becomes the blueprint for innovation in constructing the iconic edifices of tomorrow, rendering formwork more than mere molds but the foundational backbone of modern architecture and construction.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products