2月 . 03, 2025 01:41

Back to list

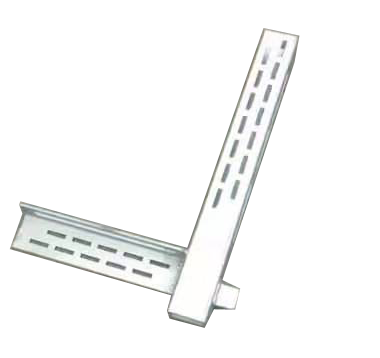

column shuttering

Column shuttering, an essential component in the world of construction, plays a pivotal role in the formation of structural columns. This temporary scaffold, often referred to as formwork, dictates the shape, structural integrity, and surface finish of columns in a variety of infrastructures, from high-rise buildings to bridges. With the relentless advance of the global construction industry, optimizing and understanding this niche product can yield significant advantages not only in project efficiency but also in quality outcomes.

Post-installation, the curing and drying phases are critical. The shuttering must remain in place until the concrete reaches adequate strength. Premature removal can lead to column cracking or failure, compromising structural integrity and potentially leading to additional costs or rework. Optimal timing for removal varies with factors such as environmental conditions, concrete mix, and specific structural demands. The trend towards technologically advanced solutions in shuttering processes cannot be overlooked. Many companies are leveraging innovations such as prefabricated formwork systems and modular designs to cut down on manual labor and accelerate project timelines. Moreover, integrating BIM (Building Information Modeling) allows precise planning, reducing errors and increasing efficiency on-site. As construction projects become more intricate and timelines more demanding, these innovative solutions offer substantial competitive advantages. Safety is another critical aspect of column shuttering. With heavy materials and rigorous processes involved, ensuring safety protocols are strictly followed is non-negotiable. Regular inspection and maintenance of shuttering materials and equipment, comprehensive safety training for workers, and adherence to local safety regulations are requisite steps in safeguarding construction workers and ensuring project success. The authority and trustworthiness of companies offering column shuttering services are bolstered by innovation, a commitment to quality, and extensive industry experience. Firms that invest in the latest technology and materials and maintain a proven track record on diverse projects stand out in a competitive market. Certifications from recognized industry bodies further elevate a company's reputability, offering peace of mind to clients. In conclusion, mastering column shuttering requires a blend of material knowledge, procedural rigour, and forward-thinking innovations. For businesses and professionals in construction, paying heed to these aspects underscores not only their expertise and reliability but also advances their proficiency in delivering projects that adhere to the highest standards of safety and quality. These efforts culminate in a construction process that is seamless, efficient, and ultimately, successful—key factors in fostering enduring reputability and trust in this ever-evolving industry.

Post-installation, the curing and drying phases are critical. The shuttering must remain in place until the concrete reaches adequate strength. Premature removal can lead to column cracking or failure, compromising structural integrity and potentially leading to additional costs or rework. Optimal timing for removal varies with factors such as environmental conditions, concrete mix, and specific structural demands. The trend towards technologically advanced solutions in shuttering processes cannot be overlooked. Many companies are leveraging innovations such as prefabricated formwork systems and modular designs to cut down on manual labor and accelerate project timelines. Moreover, integrating BIM (Building Information Modeling) allows precise planning, reducing errors and increasing efficiency on-site. As construction projects become more intricate and timelines more demanding, these innovative solutions offer substantial competitive advantages. Safety is another critical aspect of column shuttering. With heavy materials and rigorous processes involved, ensuring safety protocols are strictly followed is non-negotiable. Regular inspection and maintenance of shuttering materials and equipment, comprehensive safety training for workers, and adherence to local safety regulations are requisite steps in safeguarding construction workers and ensuring project success. The authority and trustworthiness of companies offering column shuttering services are bolstered by innovation, a commitment to quality, and extensive industry experience. Firms that invest in the latest technology and materials and maintain a proven track record on diverse projects stand out in a competitive market. Certifications from recognized industry bodies further elevate a company's reputability, offering peace of mind to clients. In conclusion, mastering column shuttering requires a blend of material knowledge, procedural rigour, and forward-thinking innovations. For businesses and professionals in construction, paying heed to these aspects underscores not only their expertise and reliability but also advances their proficiency in delivering projects that adhere to the highest standards of safety and quality. These efforts culminate in a construction process that is seamless, efficient, and ultimately, successful—key factors in fostering enduring reputability and trust in this ever-evolving industry.

Share

Next:

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products