2月 . 03, 2025 01:00

Back to list

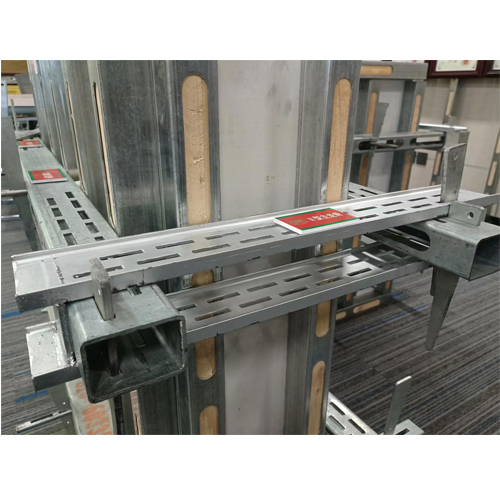

column plastic formwork

Column plastic formwork has emerged as a groundbreaking solution in the construction industry, paving the way for more efficient, sustainable, and cost-effective building practices. This innovative product offers numerous advantages over traditional methods, and understanding its benefits can empower construction professionals to improve their projects significantly.

Column plastic formwork is not only versatile in design but also adaptable to various construction environments. Whether constructing high-rise buildings, residential homes, or infrastructural projects, this formwork can adjust to project requirements. It can be easily modified to accommodate different column sizes and shapes, making it a flexible choice for architects and builders alike. By choosing plastic formwork, construction professionals can streamline their processes and adapt quickly to changing project demands. The cost-efficiency of column plastic formwork cannot be overlooked. Its initial investment is offset by reduced labor and material costs, as well as diminished waste during construction. Over time, the cumulative savings make it an economically sound choice for developers and contractors. Additionally, the ability to reuse plastic formwork multiple times results in lower per-use costs compared to single-use materials, maximizing budget efficiency. Another aspect where column plastic formwork shines is in enhancing the quality of work. With its smooth surface finish, it ensures that the concrete surfaces require minimal post-processing once the formwork is removed. This smoothness helps achieve a high-quality finish, which can often eliminate the need for additional plastering and finishing work, thereby saving both time and money. With these compelling advantages, column plastic formwork is quickly gaining recognition as an authoritative and trustworthy tool in modern construction. It reflects an integration of expert engineering practices with practical on-the-ground experience, underscoring its role as an indispensable component in achieving superior construction outcomes. Embracing this technology not only aligns with the evolving goals of the construction industry but also harnesses the expertise and authority that come from implementing cutting-edge, reliable building solutions. In conclusion, column plastic formwork represents a confluence of efficiency, expertise, and environmental responsibility. By choosing this innovative product, construction professionals can ensure more sustainable, cost-effective, and high-quality building projects, establishing a legacy of trustworthiness and excellence in their work. As the industry evolves, embracing such efficient technologies is imperative to staying competitive and meeting the increasing demand for sustainable building practices.

Column plastic formwork is not only versatile in design but also adaptable to various construction environments. Whether constructing high-rise buildings, residential homes, or infrastructural projects, this formwork can adjust to project requirements. It can be easily modified to accommodate different column sizes and shapes, making it a flexible choice for architects and builders alike. By choosing plastic formwork, construction professionals can streamline their processes and adapt quickly to changing project demands. The cost-efficiency of column plastic formwork cannot be overlooked. Its initial investment is offset by reduced labor and material costs, as well as diminished waste during construction. Over time, the cumulative savings make it an economically sound choice for developers and contractors. Additionally, the ability to reuse plastic formwork multiple times results in lower per-use costs compared to single-use materials, maximizing budget efficiency. Another aspect where column plastic formwork shines is in enhancing the quality of work. With its smooth surface finish, it ensures that the concrete surfaces require minimal post-processing once the formwork is removed. This smoothness helps achieve a high-quality finish, which can often eliminate the need for additional plastering and finishing work, thereby saving both time and money. With these compelling advantages, column plastic formwork is quickly gaining recognition as an authoritative and trustworthy tool in modern construction. It reflects an integration of expert engineering practices with practical on-the-ground experience, underscoring its role as an indispensable component in achieving superior construction outcomes. Embracing this technology not only aligns with the evolving goals of the construction industry but also harnesses the expertise and authority that come from implementing cutting-edge, reliable building solutions. In conclusion, column plastic formwork represents a confluence of efficiency, expertise, and environmental responsibility. By choosing this innovative product, construction professionals can ensure more sustainable, cost-effective, and high-quality building projects, establishing a legacy of trustworthiness and excellence in their work. As the industry evolves, embracing such efficient technologies is imperative to staying competitive and meeting the increasing demand for sustainable building practices.

Share

Next:

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products