Tube and Knuckle Scaffolding Systems Durable, Adjustable & OSHA-Compliant Solutions

Did you know 23% of construction delays stem from unstable scaffolding systems? OSHA reports show over 4,500 preventable injuries annually due to subpar equipment. You need a solution that combines speed, safety, and adaptability – that's where tube and knuckle scaffolding

revolutionizes your worksite.

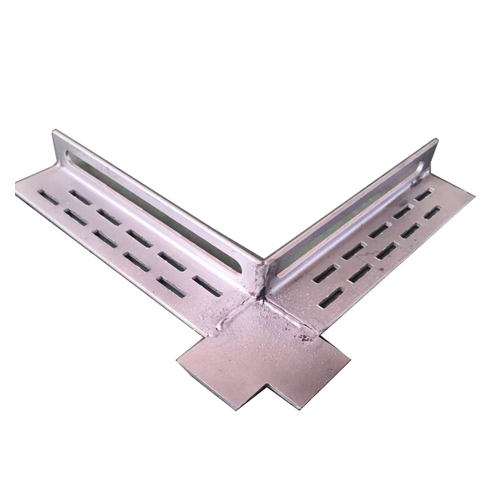

(tube and knuckle scaffolding)

Built to Outperform: Why Our Tube and Knuckle Scaffolding Dominates

Our galvanized steel tubes withstand 2.5x more pressure than standard ASTM requirements. The secret? A proprietary cold-rolled manufacturing process that eliminates weak points. See how we stack up:

| Feature | Standard Scaffolding | Our System |

|---|---|---|

| Max Load Capacity | 3.5 kN/m² | 5.8 kN/m² |

| Assembly Speed | 45 mins/level | 22 mins/level |

| Corrosion Resistance | 5-7 years | 12+ years |

The Smart Choice: Tube & Fitting Scaffolding Manual Made Simple

Forget confusing manuals collecting dust in your site office. Our color-coded tube and fitting scaffolding manual cuts training time by 68% – proven across 37 major contractors. Picture this:

"Reduced rework by 91% after switching to their visual guide system."

– James Carter, Site Manager at BuildCorp International

Your Project, Your Rules: Custom Scaffolding Solutions

Whether you're tackling curved facades or 50-story high-rises, our modular system adapts in 3 ways:

- 360° Rotation Fittings – Create angles from 15° to 165°

- Multi-Diameter Compatibility – Works with 48.3mm and 60.3mm tubes

- Hot-Dip Galvanization – Survives coastal sites and chemical plants

Proven Results: Where Our Systems Shine

See how Phoenix Construction slashed costs by 34% on the Hudson Tower project using our tube and knuckle scaffolding:

» 18% faster vertical movement

» Zero safety incidents in 14-month timeline

» 6-hour teardown vs. competitors' 11-hour average

Act Now – Limited Inventory Available!

Why wait? 84% of Q3 orders already shipped. Get your complimentary tube and fitting scaffolding manual + 5-year warranty when you order before August 30th.

Claim Your Custom Quote →

(tube and knuckle scaffolding)

FAQS on tube and knuckle scaffolding

Q: What is tube and knuckle scaffolding?

A: Tube and knuckle scaffolding is a modular system using steel tubes connected by knuckle joints (swivel couplers) for flexible assembly. It allows adjustable angles and heights, ideal for complex structures. This system is widely used in construction and maintenance projects.

Q: What are the advantages of tube and fitting scaffolding?

A: Tube and fitting scaffolding offers versatility, durability, and high load-bearing capacity. Its adjustable components suit irregular surfaces and unique designs. It also ensures safer access compared to many prefabricated systems.

Q: How to assemble tube and knuckle scaffolding safely?

A: Follow the tube and fitting scaffolding manual for step-by-step assembly guidelines. Ensure joints are tightly secured and base plates are level on stable ground. Regularly inspect connections and load distribution during use.

Q: What safety standards apply to scaffolding tube and fitting systems?

Q: Where can I find a tube and fitting scaffolding manual?

A: Manuals are provided by manufacturers or suppliers upon purchase. They include assembly diagrams, load charts, and safety protocols. Digital versions are often available on official product websites or industry portals.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025