Th2 . 15, 2025 21:21

Back to list

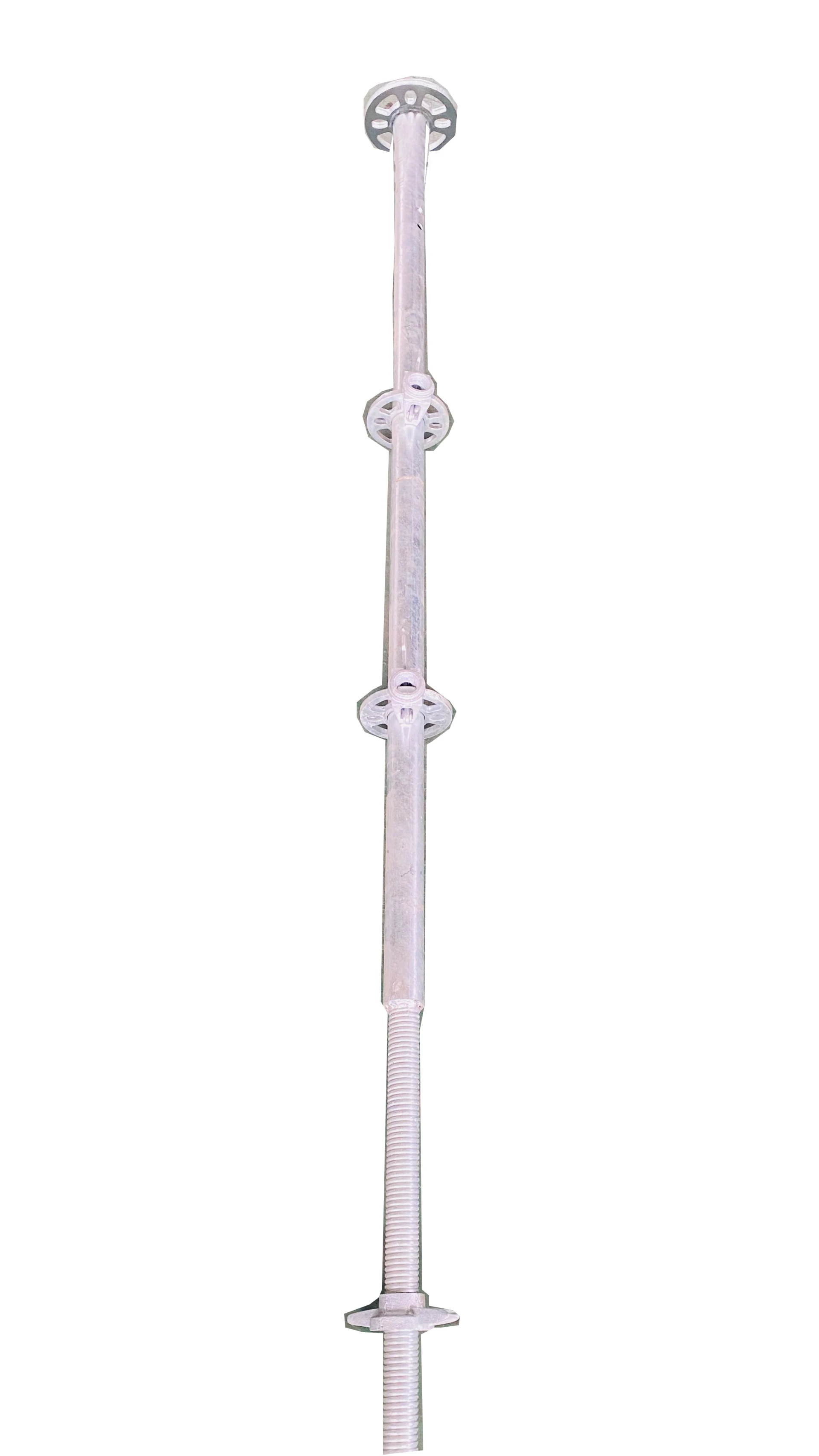

a frame scaffold

Scaffold connectors, serving as crucial components in the assembly of scaffolding systems, play a pivotal role in construction and maintenance industries. These connectors ensure the stability and safety of scaffolds, thereby protecting workers at elevated job sites. Understanding their functionality and characteristics is essential for anyone involved in construction or related fields.

The authority of knowledge in scaffold connectors comes from both extensive usage across various industries and rigorous testing protocols they undergo before reaching the market. Renowned manufacturers often submit their products for third-party testing to obtain certifications that testify to the strength, durability, and safety of their connectors. This third-party affirmation is not just a badge of trust but a prerequisite for serious professionals who understand that their reputations and workers’ safety depend on it. Trustworthiness in scaffold connectors is anchored in transparent communication from manufacturers about the limitations and proper use of their products. Providing clear instructions, specifying load capacities, and detailing the right conditions for use help end-users maximize the lifespan and functionality of the connectors. Moreover, manufacturers often provide warranties and customer support to address any issues that might arise, further reinforcing the integrity of their products. Real-world application often reveals the necessity of adaptable and easy-to-use scaffold connectors. Time is frequently a factor in construction projects, and connectors that are straightforward to install without sacrificing safety are highly valued. Adaptations such as quick-release features or compatibility with diverse scaffold systems can reduce downtime and enhance efficiency on-site. Professionals and crews who work with user-friendly connectors often find themselves diverging from overly complicated alternatives, recognizing that simplicity often equates to safety when it comes to working at height. Ultimately, the choice of scaffold connectors should align with the specific needs of a project, taking into consideration factors such as load requirements, environmental conditions, and safety specifications. Consulting with seasoned experts or collaborating with reputable suppliers can provide the necessary insights to make informed decisions. As practitioners in the field amass experience and authority on the subject, they contribute to a collective understanding that prioritizes safety and efficiency through the use of high-quality scaffold connectors. This collaborative knowledge serves as a foundation for future innovations and improvements in scaffold safety and functionality.

The authority of knowledge in scaffold connectors comes from both extensive usage across various industries and rigorous testing protocols they undergo before reaching the market. Renowned manufacturers often submit their products for third-party testing to obtain certifications that testify to the strength, durability, and safety of their connectors. This third-party affirmation is not just a badge of trust but a prerequisite for serious professionals who understand that their reputations and workers’ safety depend on it. Trustworthiness in scaffold connectors is anchored in transparent communication from manufacturers about the limitations and proper use of their products. Providing clear instructions, specifying load capacities, and detailing the right conditions for use help end-users maximize the lifespan and functionality of the connectors. Moreover, manufacturers often provide warranties and customer support to address any issues that might arise, further reinforcing the integrity of their products. Real-world application often reveals the necessity of adaptable and easy-to-use scaffold connectors. Time is frequently a factor in construction projects, and connectors that are straightforward to install without sacrificing safety are highly valued. Adaptations such as quick-release features or compatibility with diverse scaffold systems can reduce downtime and enhance efficiency on-site. Professionals and crews who work with user-friendly connectors often find themselves diverging from overly complicated alternatives, recognizing that simplicity often equates to safety when it comes to working at height. Ultimately, the choice of scaffold connectors should align with the specific needs of a project, taking into consideration factors such as load requirements, environmental conditions, and safety specifications. Consulting with seasoned experts or collaborating with reputable suppliers can provide the necessary insights to make informed decisions. As practitioners in the field amass experience and authority on the subject, they contribute to a collective understanding that prioritizes safety and efficiency through the use of high-quality scaffold connectors. This collaborative knowledge serves as a foundation for future innovations and improvements in scaffold safety and functionality.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products