Precision Concrete Cover for Rebar: Durable Protection

Understanding Concrete Cover for Rebar: A Foundation of Structural Integrity

In the realm of reinforced concrete construction, the strategic placement and precise encasement of steel reinforcing bars (rebar) are paramount to a structure's longevity and performance. This critical aspect is managed through the application of concrete cover for rebar, which refers to the depth of concrete between the surface of the rebar and the exterior surface of the concrete. Adequate cover is not merely a dimensional requirement but a fundamental engineering principle designed to protect the steel from corrosion, fire, and other environmental aggressors. Without sufficient cover, rebar can corrode, leading to expansion, cracking, and spalling of the concrete, ultimately compromising the structural integrity and necessitating costly repairs or premature replacement. Industry trends highlight a growing emphasis on high-performance concrete covers that ensure enhanced durability and sustainability across diverse construction projects.

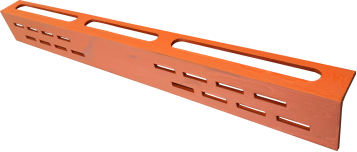

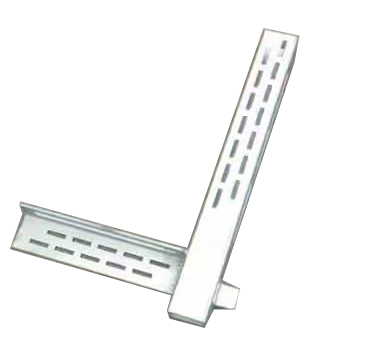

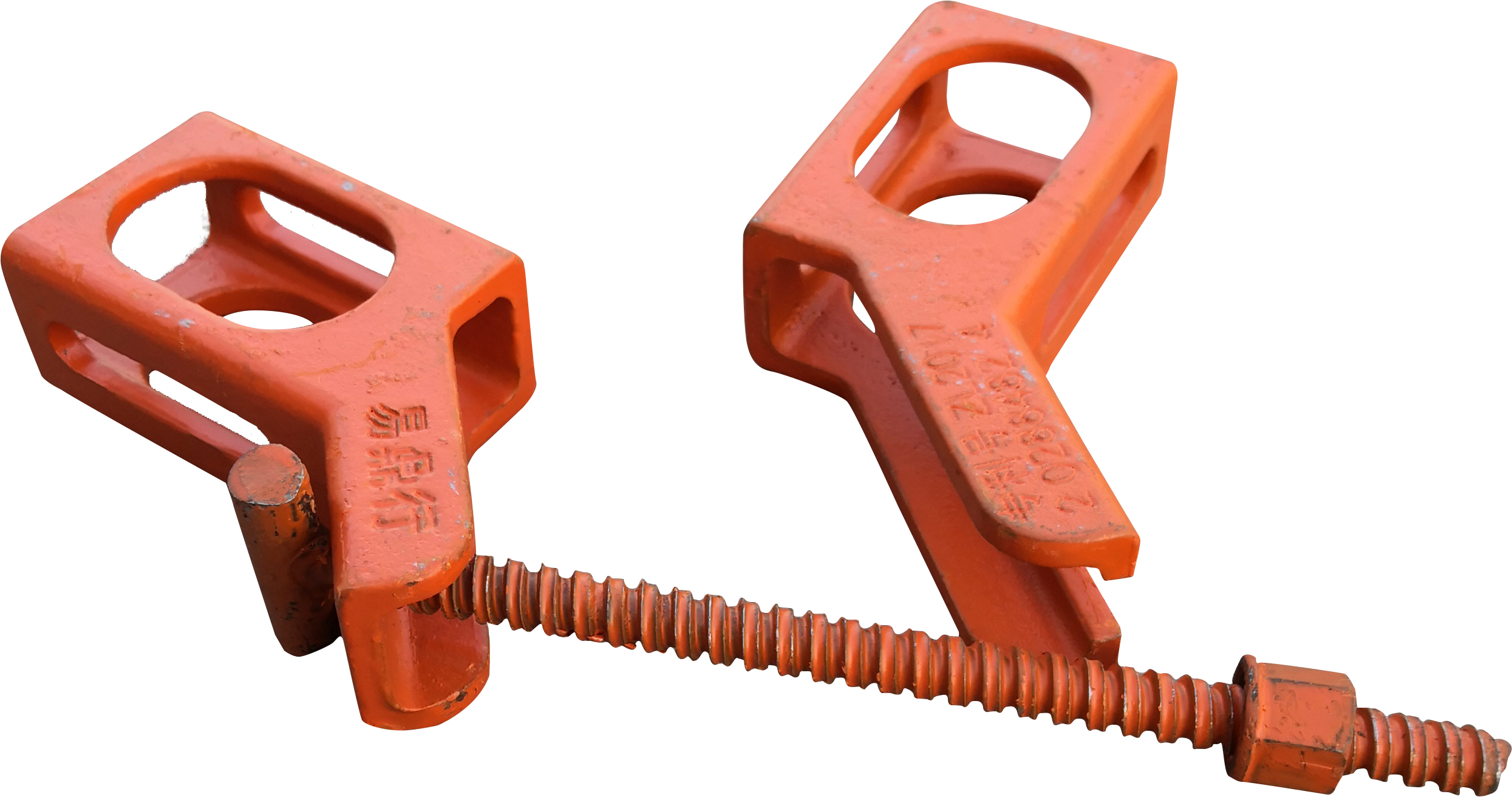

The Critical Role of Reinforcing Bar Positioners in Achieving Precise Cover

Achieving the specified thickness of concrete cover for rebar is impossible without the use of specialized tools known as reinforcing bar positioners. These accessories, often referred to as spacers or chairs, are meticulously designed to hold the rebar cage firmly in its intended position within the formwork, ensuring a uniform and accurate concrete cover on all sides. Positioners are available in various materials, including high-density plastics, cementitious compounds, and wire, each selected based on specific project requirements, environmental conditions, and load-bearing capacities during concrete pouring. For instance, plastic spacers are lightweight and cost-effective, ideal for many general applications, while cementitious spacers are preferred for their chemical compatibility with concrete and fire resistance. The correct selection and strategic placement of these positioners are crucial, as deviations can lead to insufficient cover, exposing the rebar to premature degradation and undermining the entire structure's long-term viability. Adherence to standards like ACI 318 or Eurocode 2 dictates minimum cover requirements, emphasizing the importance of these seemingly small yet vital components in structural engineering.

Manufacturing Process of Concrete Cover Spacers: Precision in Production

The manufacturing of components for concrete cover for rebar involves precise engineering and strict quality control to ensure their reliability and performance. For plastic spacers, the primary manufacturing process is injection molding, utilizing high-density polypropylene (HDPE) or other robust polymers. This method allows for complex geometries, consistent dimensions, and high production volumes. Cementitious spacers, conversely, are typically produced through casting processes, where a blend of cement, aggregates, and admixtures is precisely mixed and molded, then cured under controlled conditions to achieve specific compressive strengths and low permeability. For metallic components like wire chairs, advanced wire forming and welding techniques are employed. Throughout these processes, stringent quality assurance is maintained, often adhering to international standards such as ISO 9001 for quality management systems and specific ASTM or BS EN standards for product performance. Each batch undergoes rigorous testing for load-bearing capacity, chemical resistance, and dimensional accuracy. The typical service life of these accessories is designed to match or exceed that of the concrete structure itself, often spanning 50 to 100 years, ensuring they do not compromise the long-term integrity of the concrete cover for rebar. These precision-engineered components are critical in industries from civil infrastructure to residential and commercial construction.

Technical Parameters and Specifications for Concrete Cover Spacers

The selection of appropriate accessories for concrete cover for rebar is driven by specific technical parameters that ensure optimal performance and compliance with structural design. These parameters define the spacer's suitability for different applications and environmental conditions. Understanding these specifications is crucial for engineers and procurement specialists in making informed decisions. The table below outlines key parameters commonly considered when specifying products that ensure precise concrete cover.

| Parameter | Description | Typical Range / Values |

|---|---|---|

| Cover Depth (Nominal) | The specified distance from the rebar surface to the concrete surface. | 20mm - 75mm (0.75" - 3") |

| Material Type | Composition of the spacer. | High-density plastic (HDPE), Cementitious, Steel Wire |

| Load Capacity | Maximum weight the spacer can support without deformation. | 50 kg - 500 kg (per spacer), depending on type |

| Rebar Diameter Compatibility | Range of rebar diameters the spacer can securely hold. | 8mm - 40mm (0.3" - 1.6") |

| Chemical Resistance | Resistance to acids, alkalis, chlorides, and other aggressive chemicals. | Excellent (plastic), High (cementitious) |

| Fire Resistance Rating | Ability to maintain integrity under fire exposure. | Class A1 (non-combustible for cementitious), V-0 (self-extinguishing for plastic) |

| Temperature Range | Operational temperature range. | -40°C to +80°C (plastic), Wider for cementitious |

These parameters collectively dictate the suitability of a spacer for specific structural requirements, especially in aggressive environments where corrosion protection of the concrete cover for rebar is paramount. Thorough evaluation based on design specifications ensures the long-term integrity of the concrete structure.

Application Scenarios & Advantages in Diverse Industries

The precise application of concrete cover for rebar is indispensable across a multitude of industries, each presenting unique environmental and structural challenges. In the petrochemical sector, for instance, where structures are exposed to aggressive chemicals and corrosive elements, robust concrete cover is vital for preventing rebar degradation, thereby extending the service life of platforms, storage tanks, and pipe supports. Similarly, in metallurgy, where high temperatures and chemical fumes are common, specialized spacers ensure the structural integrity of foundations and furnace linings. For water supply and drainage systems, encompassing pipelines, reservoirs, and wastewater treatment plants, the consistent application of concrete cover for rebar is crucial for resisting water ingress and protecting against chloride-induced corrosion. Beyond these, the advantages extend to infrastructure projects like bridges and tunnels, which demand exceptional durability against environmental exposure and heavy loads. The proper use of cover ensures enhanced structural performance, reduces the need for frequent maintenance, and indirectly contributes to energy efficiency by extending the lifespan of infrastructure, deferring energy-intensive reconstruction. It embodies a proactive approach to structural preservation, offering significant long-term economic and environmental benefits across all sectors.

Advanced Materials and Cover Reinforcement Techniques

The evolution of construction materials continually enhances the effectiveness of concrete cover for rebar. Modern engineering often incorporates advanced polymer compounds in plastic spacers that offer superior chemical inertness and UV resistance, making them ideal for long-term outdoor exposure. For cementitious spacers, the introduction of high-performance concrete mixes, incorporating micro-silica or fly ash, significantly boosts compressive strength and reduces permeability, providing an even more robust protective layer for the rebar. Beyond the spacers themselves, the overall concept of cover reinforcement also encompasses innovative techniques to bolster the concrete's protective capabilities. This includes using fiber-reinforced concrete (FRC) for improved crack resistance, applying corrosion-inhibiting admixtures to the concrete mix, or utilizing epoxy-coated rebar where severe corrosive environments are anticipated. These combined strategies ensure that the specified concrete cover for rebar not only maintains its dimension but also enhances its protective qualities against aggressive agents like chlorides and sulfates, thereby extending the operational lifespan of the entire concrete structure.

Manufacturer Comparison and Selection Criteria for Concrete Cover Accessories

When selecting a supplier for concrete cover for rebar accessories, B2B decision-makers must evaluate manufacturers based on several key criteria to ensure product quality, reliability, and long-term value. Leading manufacturers distinguish themselves through rigorous adherence to international standards (e.g., ISO, ASTM), comprehensive product ranges catering to diverse rebar sizes and cover depths, and a proven track record of performance in demanding projects. Quality certifications, such as those from independent testing bodies, are non-negotiable indicators of compliance and consistency. Furthermore, consider the supplier's capacity for customization, their technical support capabilities, and the efficiency of their logistics and delivery network. A robust quality control process, from raw material inspection to final product testing, is essential for minimizing risks and ensuring the specified concrete cover for rebar is consistently achieved on-site. Manufacturers with extensive experience and strong industry partnerships often provide valuable insights and solutions, making them preferred choices for critical infrastructure and complex construction ventures.

Custom Solutions for Unique Project Requirements

While standard concrete cover for rebar spacers meet most construction needs, specialized projects often demand custom-engineered solutions. These unique scenarios might involve structures with atypical rebar configurations, aggressive environmental exposures requiring enhanced chemical resistance, or architectural concrete finishes that necessitate invisible support systems. Leading manufacturers possess the engineering expertise and production flexibility to design and produce bespoke spacers. This customization can involve specific cover depths, modified geometries to accommodate complex rebar cages, or the use of advanced composite materials for extreme conditions. Such tailored solutions ensure that even the most challenging design specifications for concrete cover for rebar are met without compromising structural integrity or aesthetic appeal. Engaging a manufacturer early in the design phase allows for collaborative development of optimal custom accessories, ensuring seamless integration and superior performance for truly unique construction endeavors.

Real-World Application Cases & Client Feedback

The effectiveness of quality concrete cover for rebar accessories is best demonstrated through their successful application in real-world projects. For instance, in a major coastal bridge construction project, the use of corrosion-resistant plastic spacers ensured consistent 75mm cover, critical for protecting rebar from chloride ingress in the marine environment. This resulted in the structure achieving its projected 100-year design life with minimal maintenance. Another case involves a high-rise commercial building where pre-cast concrete elements utilized cementitious spacers for their fire resistance and thermal compatibility, contributing to the building's robust safety profile. Client feedback consistently highlights the importance of dimensional accuracy and material durability in these accessories. Project managers frequently report that reliable reinforcing bar positioners reduce installation time, minimize costly reworks due to insufficient cover, and significantly enhance the overall quality assurance process on-site. These testimonials underscore that investing in superior components for concrete cover for rebar is a fundamental step towards achieving long-lasting and resilient concrete structures, providing tangible returns through extended service life and reduced operational expenditures.

Ensuring Quality: Inspection and Certification Standards

Adherence to rigorous inspection and certification standards is paramount for all components that contribute to the integrity of concrete cover for rebar. Key international standards such as ISO 9001 for quality management systems provide a framework for consistent production quality. Product-specific standards, including ASTM D2839 for plastic spacers and various European (e.g., BS EN 10080 for steel for concrete reinforcement) and American (e.g., ACI 117 for tolerances) codes, dictate performance requirements such as compressive strength, chemical resistance, and dimensional accuracy. Reputable manufacturers implement multi-stage quality control, from raw material testing to in-process checks during manufacturing, culminating in final product inspection. Third-party testing by accredited laboratories further validates compliance, providing an impartial assessment of product performance. This commitment to certified quality not only builds trust with B2B clients but also ensures that every component contributing to the concrete cover for rebar will perform as expected under design conditions, mitigating risks and ensuring the long-term structural health of the concrete elements.

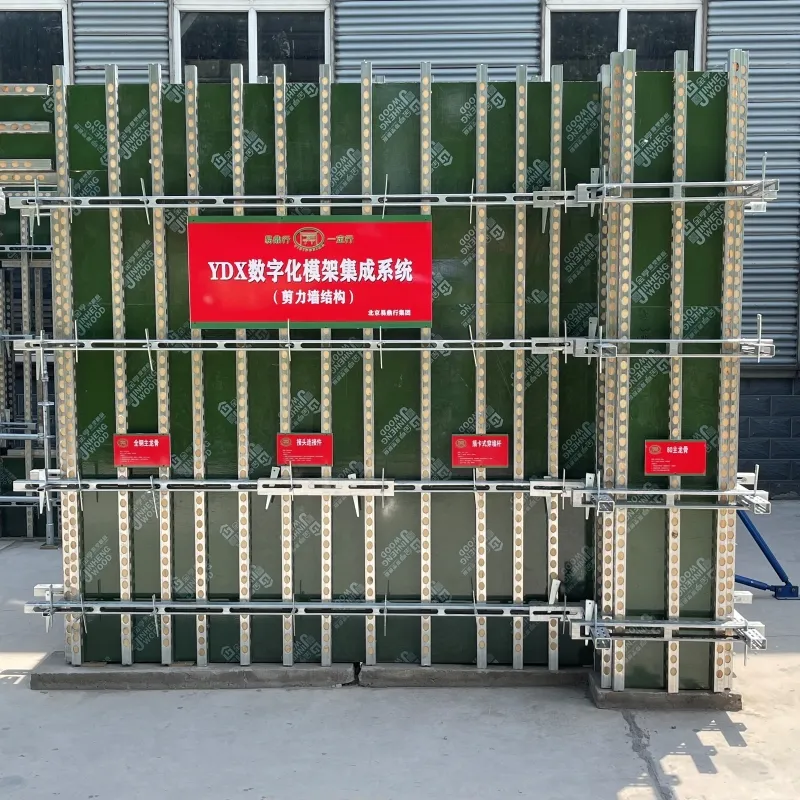

The Role of Slotted Angle Steel and Rack Slotted Angle in Construction Support

While directly unrelated to the material composition of concrete cover for rebar spacers, materials like slotted angle steel and rack slotted angle play an important auxiliary role in the broader construction environment, impacting the efficiency and organization of projects where precise concrete cover is critical. Slotted angle steel is frequently utilized in the construction of temporary support structures, formwork bracing, and on-site storage solutions for construction materials, including rebar and cover accessories. Its versatility, ease of assembly, and disassembly make it ideal for creating custom shelving or frameworks that help organize materials, reducing clutter and improving accessibility for workers installing `reinforcing bar positioners` and other components that ensure proper cover. Similarly, rack slotted angle systems can be configured to create robust, customizable storage racks for larger quantities of rebar, formwork panels, or even finished concrete cover elements awaiting installation. By facilitating an organized and efficient construction site, these versatile steel components indirectly contribute to a smoother workflow, which in turn supports the precise and timely placement of rebar and the proper application of concrete cover for rebar, minimizing potential delays or errors that could compromise structural quality.

Longevity and Maintenance Considerations for Concrete Structures

The longevity of reinforced concrete structures is intrinsically linked to the efficacy of the concrete cover for rebar. A well-designed and properly executed cover significantly extends the service life of a structure by providing an impermeable barrier against corrosive agents. Factors influencing this longevity include the quality of the concrete mix, the type and placement accuracy of the spacers, and the ambient environmental conditions. Structures in aggressive environments, such as coastal areas with high chloride exposure or industrial zones with chemical pollutants, require thicker and often denser concrete cover for rebar, typically combined with specialized corrosion-resistant additives or coatings. While proper initial installation minimizes the need for extensive maintenance, periodic inspections are recommended to identify any signs of spalling or cracking, which could indicate cover deficiency. Early detection allows for targeted repairs, preserving the integrity of the rebar and preventing more widespread deterioration. Investing in high-quality cover accessories during construction is a proactive measure that reduces future maintenance costs and ensures a structure's sustained performance over its intended design life.

Technical Advantages: Corrosion Resistance and Structural Integrity

The primary technical advantage of adequate concrete cover for rebar lies in its unparalleled ability to provide robust corrosion resistance to the embedded steel reinforcement. Concrete naturally forms a passive layer around rebar, protecting it from oxidation. However, this passivation can be compromised by the ingress of aggressive substances such as chlorides (from de-icing salts or marine environments) or carbon dioxide (leading to carbonation). Sufficient concrete cover acts as a physical and chemical barrier, significantly delaying the penetration of these harmful agents. A greater depth of cover increases the time it takes for such substances to reach the rebar, thereby prolonging the steel's passive state and preventing rust. This directly translates to enhanced structural integrity and safety. Corroding rebar expands, inducing tensile stresses in the surrounding concrete, leading to cracking, spalling, and ultimately, a reduction in the load-bearing capacity of the structure. By effectively safeguarding the rebar, optimal concrete cover for rebar preserves the composite action between steel and concrete, ensuring the structure maintains its design strength and ductility throughout its intended lifespan, proving essential for both safety and economic performance.

Delivering Excellence: Lead Times and Global Reach

For B2B clients in the construction sector, reliable lead times and extensive global reach are as critical as product quality when sourcing components for concrete cover for rebar. Project schedules are often tightly managed, making timely delivery of essential accessories paramount. Leading manufacturers understand this imperative, implementing sophisticated supply chain management systems to optimize production, inventory, and logistics. Typical lead times for standard spacers can range from a few days for readily available stock to several weeks for large, custom orders or specialized materials. Manufacturers with established global distribution networks can efficiently serve projects across continents, navigating complex customs regulations and transportation logistics. This capability ensures that regardless of project location, high-quality concrete cover for rebar accessories are accessible, minimizing delays and maintaining project momentum. A robust logistics framework and a commitment to on-time delivery underscore a manufacturer's dedication to supporting their clients' critical project timelines and operational continuity.

Comprehensive Quality Assurance and Warranty for Accessories

A commitment to comprehensive quality assurance and robust warranty terms is a hallmark of reputable suppliers of concrete cover for rebar accessories. Quality assurance processes begin with the rigorous selection and testing of raw materials, ensuring they meet stringent performance specifications for durability, chemical resistance, and structural integrity. Throughout the manufacturing cycle, in-line inspections, statistical process control, and final product testing are conducted to verify dimensional accuracy, load-bearing capacity, and material consistency. Certifications from recognized bodies like ISO and compliance with industry-specific standards provide independent validation of these processes. Furthermore, a strong warranty commitment offers clients peace of mind, demonstrating the manufacturer's confidence in their product's performance and durability. This typically covers defects in materials and workmanship for a specified period, offering recourse and support should any issues arise. This comprehensive approach to quality and warranty ensures that the accessories providing concrete cover for rebar not only perform reliably upon installation but also contribute to the long-term resilience and safety of the concrete structure itself.

Dedicated Customer Support and After-Sales Service

In the B2B landscape, the value of dedicated customer support and comprehensive after-sales service for products like concrete cover for rebar cannot be overstated. Beyond the initial purchase, clients often require technical assistance, installation guidance, or troubleshooting support. A leading manufacturer provides readily accessible expert advice, ensuring that engineers and construction teams can optimize the use of their products and address any on-site challenges effectively. This includes offering detailed product specifications, installation manuals, and even on-site training if needed. Robust after-sales service also encompasses efficient handling of queries, timely resolution of any product-related issues, and maintaining consistent communication. This level of support fosters long-term partnerships, building trust and confidence in the manufacturer's commitment to their clients' success. For critical components that directly impact the structural integrity of a building, such as those establishing concrete cover for rebar, responsive and knowledgeable customer service is an invaluable asset that helps ensure project success and client satisfaction.

Frequently Asked Questions (FAQ) About Concrete Cover

Why is Concrete Cover for Rebar Important?

Concrete cover for rebar is crucial because it provides the primary defense for steel reinforcement against corrosion, fire, and mechanical damage. It acts as a protective barrier, preventing moisture, chlorides, and carbon dioxide from reaching the rebar, which can lead to rust and expansion, compromising the structural integrity of the concrete element.

What are Reinforcing Bar Positioners?

Reinforcing bar positioners (also known as spacers or chairs) are small devices used to maintain the correct spacing and position of rebar within the formwork, ensuring the specified depth of concrete cover for rebar is achieved. They come in various materials like plastic, cement, or wire, chosen based on load, environment, and required cover depth.

How Does Cover Reinforcement Improve Durability?

Cover reinforcement refers to techniques and materials that enhance the protective capabilities of the concrete cover. This includes selecting appropriate cover depth, using high-quality spacers, incorporating corrosion inhibitors into the concrete mix, and sometimes employing fiber-reinforced concrete to improve crack resistance, all contributing to longer structural life.

What Standards Apply to Concrete Cover Accessories?

Various international and national standards apply, including ISO 9001 for quality management, and specific material and performance standards from organizations like ASTM (American Society for Testing and Materials) and BS EN (British Standards European Norms), ensuring products meet critical specifications for strength, durability, and dimensional accuracy for concrete cover for rebar applications.

The Future of Concrete Cover Technology

The future of concrete cover for rebar technology is poised for innovation, driven by advancements in materials science, digital construction, and a growing demand for sustainable infrastructure. Research is focusing on smart spacers embedded with sensors to monitor concrete curing and rebar corrosion in real-time, providing invaluable data for predictive maintenance. The development of self-healing concrete, which can automatically repair micro-cracks, promises to enhance the longevity of the cover itself. Furthermore, the integration of Building Information Modeling (BIM) with precise digital models of rebar cages and spacer placements will streamline the design and construction process, ensuring optimal concrete cover for rebar with unprecedented accuracy. These technological leaps aim to not only extend the service life of concrete structures but also to make construction processes more efficient, sustainable, and resilient in the face of evolving environmental challenges and structural demands, cementing the critical role of these seemingly small components in large-scale engineering feats.

Authoritative References

- American Concrete Institute (ACI) Standards Committee 318. Building Code Requirements for Structural Concrete and Commentary.

- European Committee for Standardization (CEN). Eurocode 2: Design of concrete structures.

- International Organization for Standardization (ISO) 9001: Quality management systems – Requirements.

- ASTM International. Standard Specification for Plastic Spacers, Chairs, and Bar Supports for Reinforcing Steel.

- Journal of Civil Engineering and Construction. Studies on concrete durability and rebar corrosion.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025