Th1 . 14, 2025 10:35

Back to list

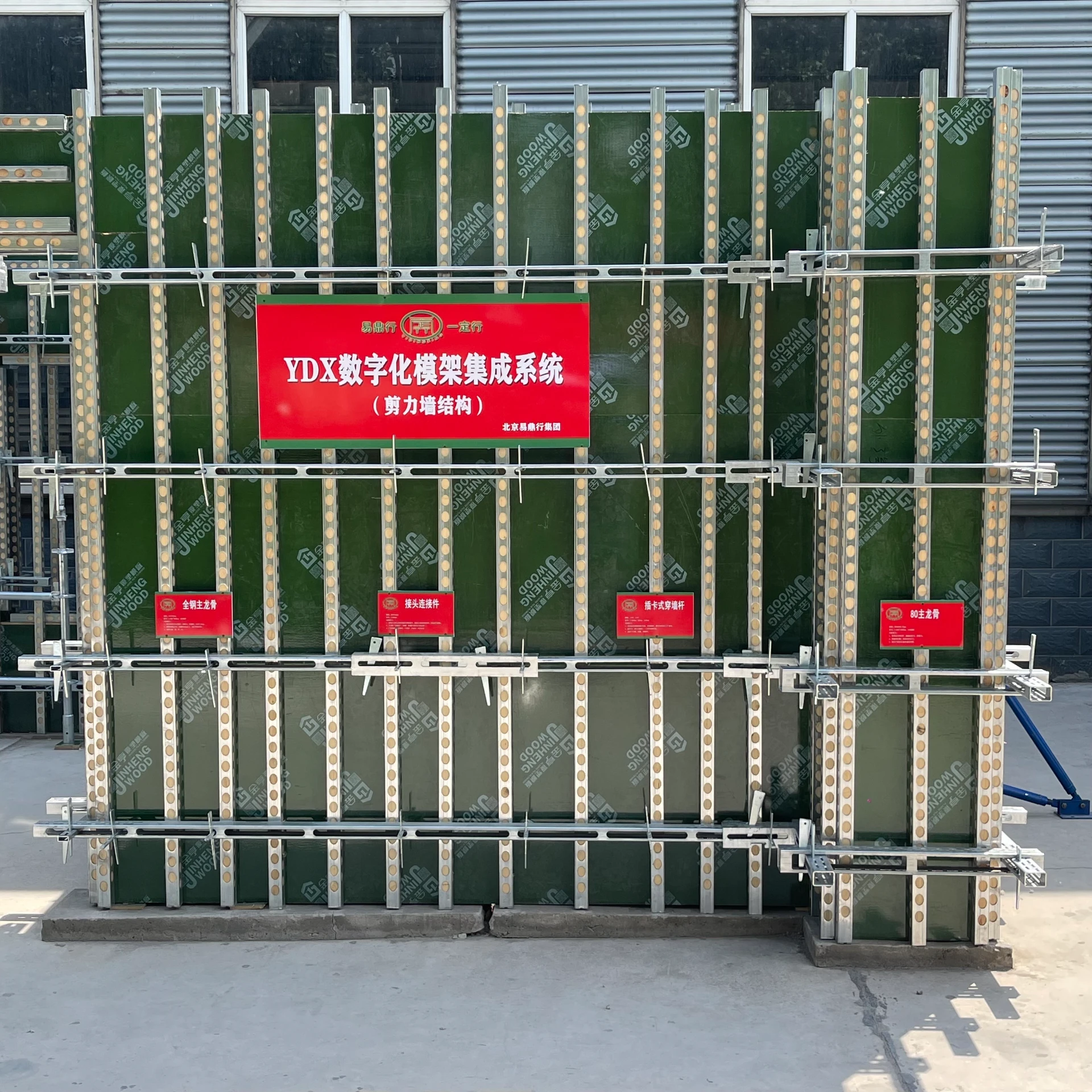

concrete base formwork

Concrete base formwork plays a pivotal role in the construction industry, aiding builders in shaping and forming the foundational elements of various structures. As an indelible component of construction, formwork demands expertise to ensure structural integrity, cost-effectiveness, and efficiency.

Beyond execution, the authority in formwork practices is demonstrated through adhering to regional safety standards and regulations. Experienced providers ensure constant collaboration with engineers and project managers to implement formwork systems that meet stringent safety criteria, thereby reducing risk factors that could potentially result in accidents or project delays. Trust, an invaluable currency in the construction sector, is built on the consistent delivery of safe and efficient work conditions, fostering long-term business relationships and reputation growth. Investing in innovative formwork technologies is witnessing a rise, with smart formwork solutions becoming increasingly prevalent. These systems allow for better monitoring of concrete curing processes and can alert construction teams of potential issues before they cause significant setbacks. An illustrative example is the use of digital formwork sensors that provided real-time data, leading to more efficient scheduling and resource allocation in a recent urban infrastructure project. In the competitive landscape of the construction industry, the mark of expertise lies in reliable, scalable solutions that balance the intricate aspects of cost, labor, and quality. Whether through time-honed skills or the adoption of cutting-edge technology, successful concrete base formwork relies on precision and informed choices. The stakes are high—quality formwork can transform the potential pitfalls of construction into a testament of engineering prowess and project management expertise. By embracing a blend of traditional practices and modern innovations, concrete base formwork stands as a cornerstone of successful construction projects. Establishing this balance ensures that stakeholders can place their confidence in each structure's durability and safety, thus optimizing the value and longevity of their investments.

Beyond execution, the authority in formwork practices is demonstrated through adhering to regional safety standards and regulations. Experienced providers ensure constant collaboration with engineers and project managers to implement formwork systems that meet stringent safety criteria, thereby reducing risk factors that could potentially result in accidents or project delays. Trust, an invaluable currency in the construction sector, is built on the consistent delivery of safe and efficient work conditions, fostering long-term business relationships and reputation growth. Investing in innovative formwork technologies is witnessing a rise, with smart formwork solutions becoming increasingly prevalent. These systems allow for better monitoring of concrete curing processes and can alert construction teams of potential issues before they cause significant setbacks. An illustrative example is the use of digital formwork sensors that provided real-time data, leading to more efficient scheduling and resource allocation in a recent urban infrastructure project. In the competitive landscape of the construction industry, the mark of expertise lies in reliable, scalable solutions that balance the intricate aspects of cost, labor, and quality. Whether through time-honed skills or the adoption of cutting-edge technology, successful concrete base formwork relies on precision and informed choices. The stakes are high—quality formwork can transform the potential pitfalls of construction into a testament of engineering prowess and project management expertise. By embracing a blend of traditional practices and modern innovations, concrete base formwork stands as a cornerstone of successful construction projects. Establishing this balance ensures that stakeholders can place their confidence in each structure's durability and safety, thus optimizing the value and longevity of their investments.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products