Th2 . 19, 2025 11:41

Back to list

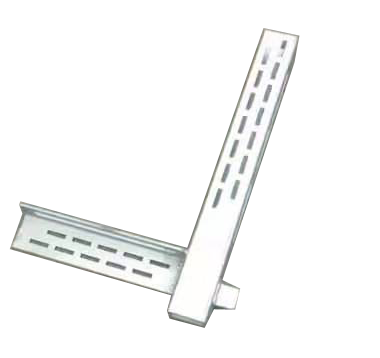

Scaffolding

Alloy scaffolding tubes have revolutionized the construction industry, offering an unrivaled blend of strength, durability, and flexibility. These tubes, typically crafted from a combination of metals like aluminum and steel, offer superior weight-to-strength ratio, making them a choice material for various construction applications. In the world of construction, where safety, reliability, and efficiency are paramount, alloy scaffolding tubes stand as a testament to engineering prowess and material innovation.

From a safety perspective, the use of alloy scaffolding tubes aligns with stringent industry standards and safety regulations. Their strength and durability come together to create a robust system that minimizes the risk of accidents. Construction sites using alloy scaffolding have reported fewer incidents of scaffold collapse or failure, underscoring the reliability of this material in maintaining a safe working environment. Furthermore, the environmental impact of construction materials is becoming increasingly important. Alloy scaffolding tubes, especially those utilizing recyclable materials, align well with green building practices. Aluminum, a common component of these tubes, is highly reusable, supporting sustainability initiatives in the industry. By choosing alloy scaffolding tubes, construction companies not only contribute to a safer work environment but also support environmentally responsible practices. The authority in material science and construction technology poises alloy scaffolding tubes as the future of scaffolding solutions. Their technical merits, combined with empirical evidence from field applications, make them a preferred choice for engineers and architects who prioritize safety, efficiency, and sustainability in construction projects. In conclusion, alloy scaffolding tubes exemplify excellence in modern construction material science. They resonate with the industry's demand for materials that provide high performance in terms of strength, durability, and adaptability. As industry professionals continue to strive for enhanced safety and efficiency, alloy scaffolding tubes are likely to remain at the forefront of construction material innovation. For construction firms looking to maximize their project outcomes while minimizing risks, the deployment of alloy scaffolding tubes represents an optimal solution that harmonizes with the highest standards of engineering excellence.

From a safety perspective, the use of alloy scaffolding tubes aligns with stringent industry standards and safety regulations. Their strength and durability come together to create a robust system that minimizes the risk of accidents. Construction sites using alloy scaffolding have reported fewer incidents of scaffold collapse or failure, underscoring the reliability of this material in maintaining a safe working environment. Furthermore, the environmental impact of construction materials is becoming increasingly important. Alloy scaffolding tubes, especially those utilizing recyclable materials, align well with green building practices. Aluminum, a common component of these tubes, is highly reusable, supporting sustainability initiatives in the industry. By choosing alloy scaffolding tubes, construction companies not only contribute to a safer work environment but also support environmentally responsible practices. The authority in material science and construction technology poises alloy scaffolding tubes as the future of scaffolding solutions. Their technical merits, combined with empirical evidence from field applications, make them a preferred choice for engineers and architects who prioritize safety, efficiency, and sustainability in construction projects. In conclusion, alloy scaffolding tubes exemplify excellence in modern construction material science. They resonate with the industry's demand for materials that provide high performance in terms of strength, durability, and adaptability. As industry professionals continue to strive for enhanced safety and efficiency, alloy scaffolding tubes are likely to remain at the forefront of construction material innovation. For construction firms looking to maximize their project outcomes while minimizing risks, the deployment of alloy scaffolding tubes represents an optimal solution that harmonizes with the highest standards of engineering excellence.

Share

Next:

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products