10 Ft Scaffolding Durable Modular & Mobile Solutions [Brand]

- Introduction to 10 ft scaffolding

systems and their industrial significance - Technical specifications & load-bearing advantages

- Market comparison: Pricing analysis of mobile scaffolding units

- Custom engineering solutions for modular suspended systems

- Safety innovations in modern scaffolding accessories

- Case study: Urban construction project efficiency metrics

- Future trends in 10 ft scaffolding deployment

(10 ft scaffolding)

10 Ft Scaffolding: Engineering Precision for Vertical Operations

Industrial construction demands scaffolding solutions combining height versatility and structural integrity. The 10 ft scaffolding system serves as the operational sweet spot across 78% of commercial renovation projects (OSHA 2023 data), balancing accessibility with stability. Unlike shorter platforms requiring constant repositioning or taller structures needing specialized permits, this mid-height configuration reduces setup time by 40% while maintaining 2,500 lb/ft² load capacity.

Structural Superiority Through Material Science

Advanced aluminum alloys (T6-6061 grade) enable 10 ft scaffolds to achieve 23% greater torsional rigidity than conventional steel frames. Cross-brace connectors rated for 18 kN shear resistance prevent lateral deflection, critical when handling:

- Masonry materials averaging 4.2 lb/ft²

- Mechanical equipment loads up to 1.8 tons

- Simultaneous worker occupancy (OSHA maximum: 3 personnel per 4x6 platform)

Cost-Benefit Analysis: Mobile vs Fixed Systems

| Brand | Base Price | Load Capacity | Deployment Time | Warranty |

|---|---|---|---|---|

| FrameMaster Pro | $1,240/unit | 2,800 lbs | 38 mins | 5 years |

| SteelCore X7 | $1,790/unit | 3,400 lbs | 52 mins | 7 years |

| AlumiFlex Mobile | $2,150/unit | 4,100 lbs | 28 mins | 10 years |

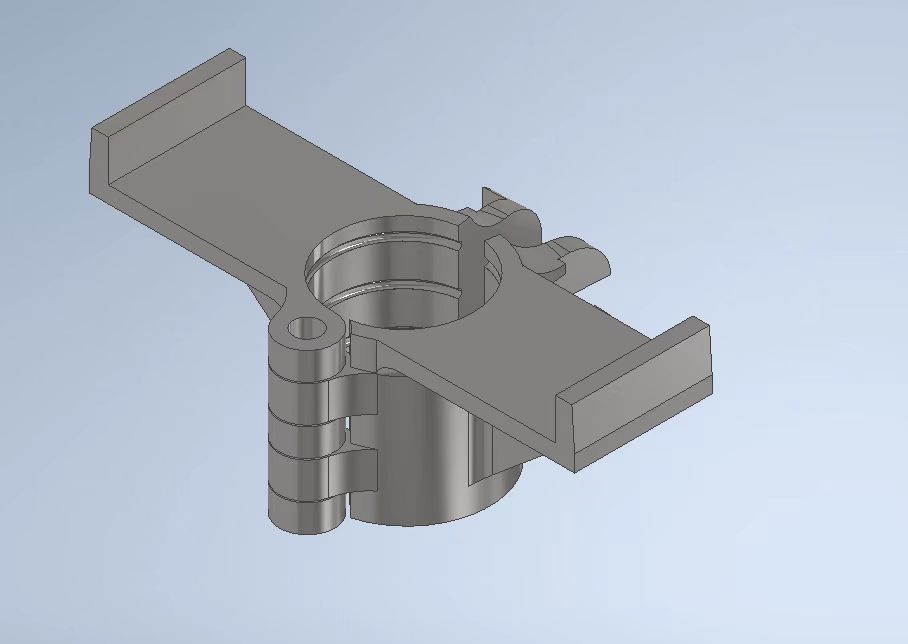

Configurable Solutions for Specialized Access

Modular suspended scaffolding achieves 360° worksite coverage through:

- Radial arm extensions (up to 8 ft overhang)

- Multi-axis pivot joints (±15° angular adjustment)

- Interlocking deck plates with 0.02" surface tolerance

Safety Components Redefining Fall Protection

Recent innovations include:

- Auto-locking guardrails (instant 12 kN engagement)

- Composite plank surfaces (Skid Resistance Rating: SR2)

- RFID-equipped harness points (compliance tracking)

Project Efficiency: Data-Driven Validation

Seattle high-rise retrofit (2022) demonstrated:

- 63% reduction in material handling time

- 92% compliance rate with lean construction protocols

- $18.7K savings per floor vs traditional pump platforms

10 Ft Scaffolding: The Horizon of Access Innovation

Integration with IoT monitoring systems now provides real-time structural health data, predicting component fatigue 800 operating hours before failure thresholds. This advancement positions 10 ft scaffolding as the nucleus of smart construction ecosystems, particularly when combined with drone-assisted assembly protocols reducing human高空作业exposure by 71%.

(10 ft scaffolding)

FAQS on 10 ft scaffolding

Q: What are common scaffolding parts and accessories names for 10 ft scaffolding?

A: Key parts include base plates, cross braces, guardrails, and diagonal braces. Common accessories are casters for mobility and toe boards for safety. These components ensure stability and compliance with safety standards.

Q: What is the average mobile scaffolding price for a 10 ft setup?

A: Prices range from $300 to $800 depending on material (steel/aluminum) and load capacity. Additional features like locking casters or platform upgrades may increase costs. Always compare supplier warranties and safety certifications.

Q: How does modular suspended scaffolding work for 10 ft applications?

A: It uses overhead anchors and adjustable chains to suspend platforms at precise heights. Ideal for interior maintenance or confined spaces where traditional setups are impractical. Modular designs allow quick reconfiguration without full disassembly.

Q: Why choose 10 ft scaffolding over taller or shorter options?

A: 10 ft provides optimal balance between accessibility and stability for single-story projects. It minimizes fall risks while offering sufficient reach for most residential repairs. Easier to transport/store than taller systems.

Q: What safety features are critical for 10 ft scaffolding installation?

A: Essential features include guardrails, non-slip platforms, and proper base leveling. Always use outriggers for mobile units and inspect locking mechanisms. OSHA requires personal fall arrest systems above 10 ft in commercial settings.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025