ม.ค. . 14, 2025 11:54

Back to list

Timber Steel

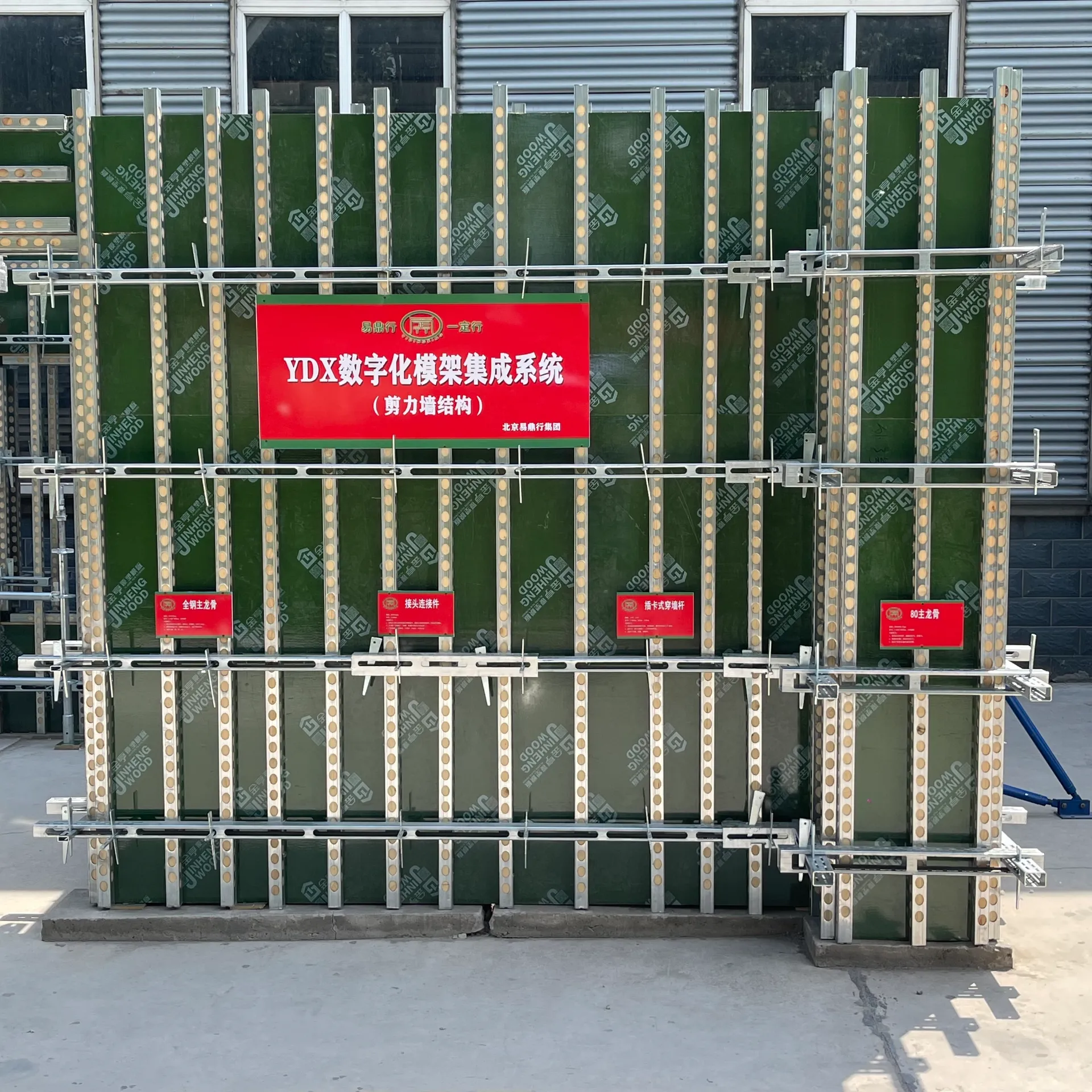

Formwork systems are critical in constructing beams and slabs, particularly in projects aiming for high efficiency and quality. The selection of an appropriate formwork greatly influences the project timeline, cost, and overall safety. Understanding how to choose and implement the best formwork for beams and slabs is vital for construction professionals seeking to uphold the highest standards of expertise and reliability.

Authoritative sources in the construction industry emphasize the importance of safety in formwork erection and dismantling. High-quality formwork products are engineered with safety features like guardrails and nonslip surfaces, reducing the risk of accidents on the construction site. Trustworthy manufacturers provide certification and testing results that validate the safety and performance of their products, adding a layer of confidence for project managers and engineers. Building trust with stakeholders involves demonstrating a commitment to quality and reliability. By leveraging state-of-the-art formwork systems, construction companies can showcase their expertise in delivering superior structures. Continuous learning and adaptation to new technologies are integral to maintaining an authoritative presence in the construction field. To maximize the lifespan of formwork systems, comprehensive maintenance protocols should be implemented. Cleaning and storage procedures play a crucial role in ensuring the formwork remains in optimal condition for subsequent uses. Regular inspections and timely repairs further prolong the usability of the formwork, preventing unexpected costs and delays. In summary, the sophisticated selection and application of formwork systems for beams and slabs are cornerstones of modern construction practices. By focusing on cutting-edge products and technologies, construction professionals can elevate their projects, ensuring both safety and efficiency. A deep understanding of formwork systems not only enhances project outcomes but also solidifies a company's reputation as a leader in the industry. This approach to formwork not only embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness but also guarantees a competitive edge in today's dynamic construction landscape.

Authoritative sources in the construction industry emphasize the importance of safety in formwork erection and dismantling. High-quality formwork products are engineered with safety features like guardrails and nonslip surfaces, reducing the risk of accidents on the construction site. Trustworthy manufacturers provide certification and testing results that validate the safety and performance of their products, adding a layer of confidence for project managers and engineers. Building trust with stakeholders involves demonstrating a commitment to quality and reliability. By leveraging state-of-the-art formwork systems, construction companies can showcase their expertise in delivering superior structures. Continuous learning and adaptation to new technologies are integral to maintaining an authoritative presence in the construction field. To maximize the lifespan of formwork systems, comprehensive maintenance protocols should be implemented. Cleaning and storage procedures play a crucial role in ensuring the formwork remains in optimal condition for subsequent uses. Regular inspections and timely repairs further prolong the usability of the formwork, preventing unexpected costs and delays. In summary, the sophisticated selection and application of formwork systems for beams and slabs are cornerstones of modern construction practices. By focusing on cutting-edge products and technologies, construction professionals can elevate their projects, ensuring both safety and efficiency. A deep understanding of formwork systems not only enhances project outcomes but also solidifies a company's reputation as a leader in the industry. This approach to formwork not only embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness but also guarantees a competitive edge in today's dynamic construction landscape.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products