ก.ค. . 28, 2025 09:01

Back to list

Premium Scaffolding for Sale | Aluminium & Mobile Scaffold | A Frame Options

Discover scaffolding for sale — your go-to solution for safe, flexible, and standards-compliant access for construction, petrochemical maintenance, industrial installation, and interior work. We cover the latest scaffolding trends, state-of-the-art technology, performance parameters, manufacturing processes, and best-in-class scaffolding for sale providers. This guide analyzes industry data, expert comparisons, technical diagrams, and proven case studies.

All-in-One Scaffolding for Sale Solutions

Industry Trends in Scaffolding for Sale

The global scaffolding market reached USD 51.2 billion in 2023, projected to grow at a CAGR of 5.3% through 2029 (Mordor Intelligence). Increased demand for aluminium scaffolding for sale is driven by lightweight, high-tensile alloys, corrosion-resistance, and ease of assembly. Mobile scaffolds and A Frame scaffolds are gaining popularity for rapid deployment and safety.

Aluminium Scaffolding for Sale at Construction Site

| Type | Material | Load Class (kg/m2) | Height Range | Standard | Typical Usage |

|---|---|---|---|---|---|

| A Frame Scaffold | Steel / Aluminium | 250–600 | 2-15 m | ANSI/SSFI SC100-5/05 | General Construction, Facade |

| Aluminium Mobile Scaffold | 6061-T6 Aluminium | 180–300 | 1–12 m | EN 1004, ISO 9001:2015 | Indoor, Maintenance |

| Ringlock Scaffolding | Q235/Q345 Steel | 300–750 | Up to 30 m | EN 12811, ISO 3834 | Industrial, Petrochemical |

| Suspended Scaffolding | Steel | 200–450 | Variable | OSHA 1926.451 | Elevated Repairs |

Quick-Deploy Mobile Scaffold for Sale

Manufacturing Process Flow: Scaffolding for Sale

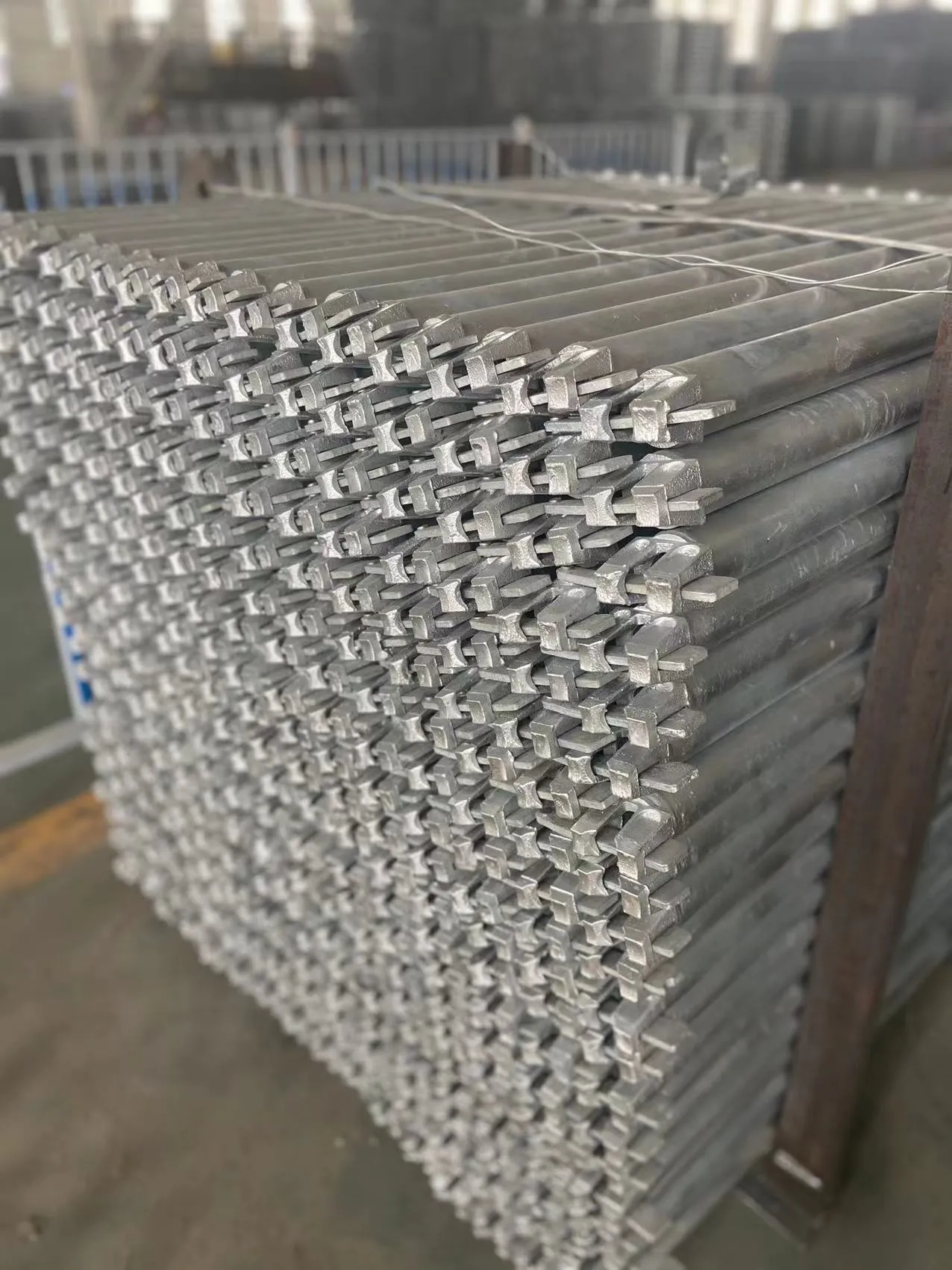

Reliable scaffolding for sale follows stringent engineering protocols, including raw material selection, advanced forming, precision machining (CNC), strict welding, surface treatment (hot-dip galvanizing, powder coating), NDT, and load testing.

Scaffolding Manufacturing Process Flow Chart

- Raw Material Selection: High-tensile 6061-T6 aluminium or Q235B/Q345 steel, certified by ISO 9001/EN 1004.

- Forming: Hydraulic pressing, roll-forming, and precision tube bending for modularity.

- CNC Machining: Tolerance up to ±0.5mm, for lugs, connections, and platform slots.

- Welding: MIG/robotic welding (ISO 3834 certified) ensures consistent strength.

- Galvanizing/Coating: Hot-dip, powder-coating, or anodizing for anti-corrosion (per ASTM A123).

- Testing & QA: Non-Destructive Testing, load/impact tests (EN 12811) for safety compliance.

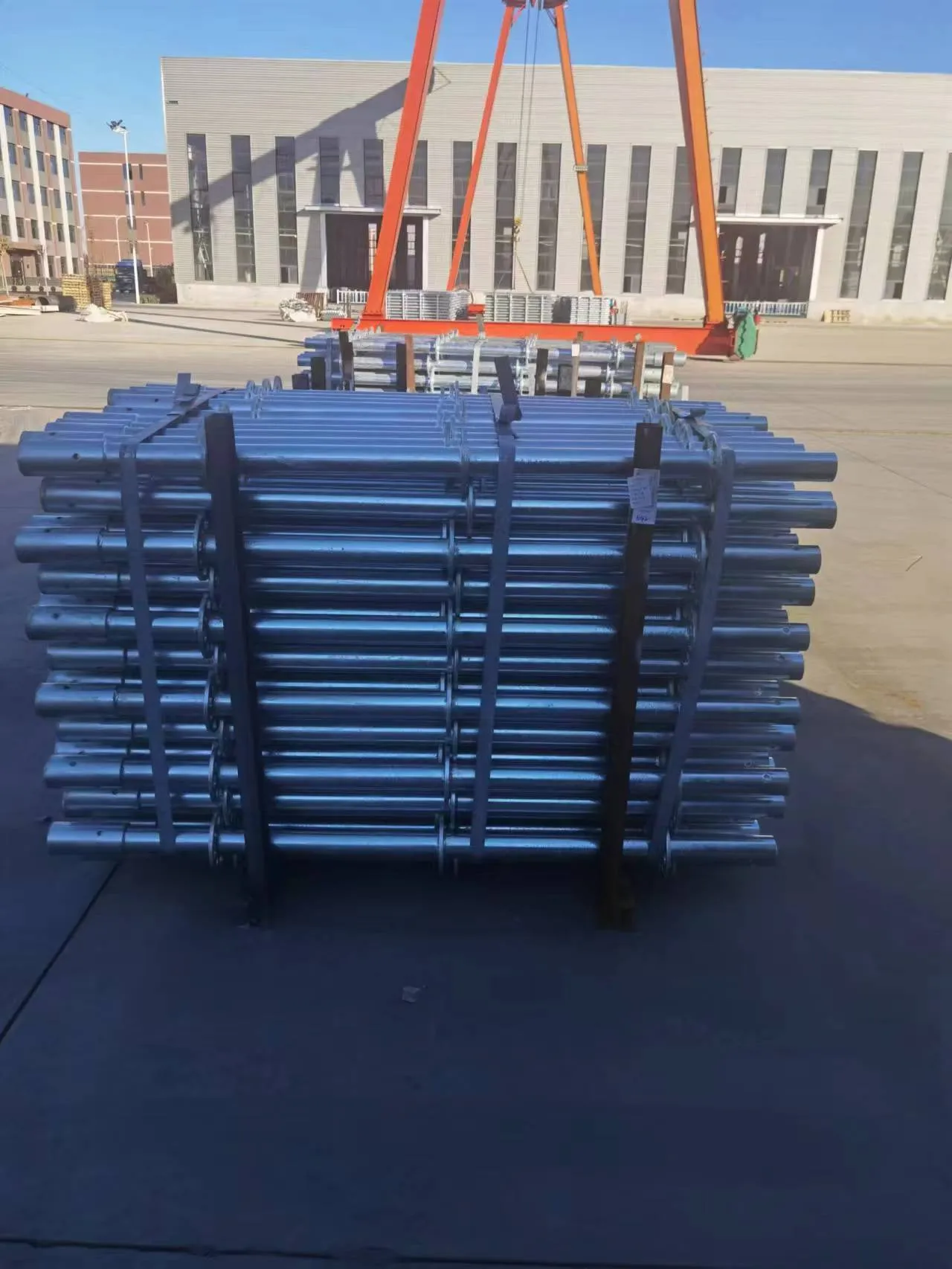

- Packing & Logistics: Palletized, shrink-wrapped, edge-protection, with customs/ISO labels.

Precision CNC Machining of Scaffold Components

Technical Advantages of Modern Scaffolding for Sale

High Strength Alloys

Material: 6061-T6 Aluminium & Q235/Q345 Steel.Advantage: 40% higher weight-to-strength ratio vs traditional steel scaffold; load class up to 750 kg/m².

Impact: Lightweight yet robust for safe stacking to 30m+ heights.

Corrosion Resistance

Treatment: Multi-stage hot-dip galvanizing or anodizing.Standards: ASTM A123/ISO 1461.

Performance: 10–15 year rust-free service life in petrochemical plants.

Modular & Quick Assembly

Design: Lock-pin, snap-on, wedge-lock, and ringlock modules.Time Saving: Up to 60% faster installation/decommission (source).

Corrosion-Proof Scaffolding for Sale for Outdoor Industrial Sites

Industry Data Visualization & Market Trends

Global Scaffolding Market Size (2016–2024E)

■ Market Size (USD billion)

◆ Aluminium Scaffolding Share (%)

Versatile Application: Scaffolding in Complex Maintenance

Scaffolding Type Comparison (Load, Weight, Cost)

A Frame Scaffold for Facade and Maintenance Work

Key Technical Specifications — Scaffolding for Sale

| Parameter | Frame Scaffold | Aluminium Scaffold | Ringlock Scaffold |

|---|---|---|---|

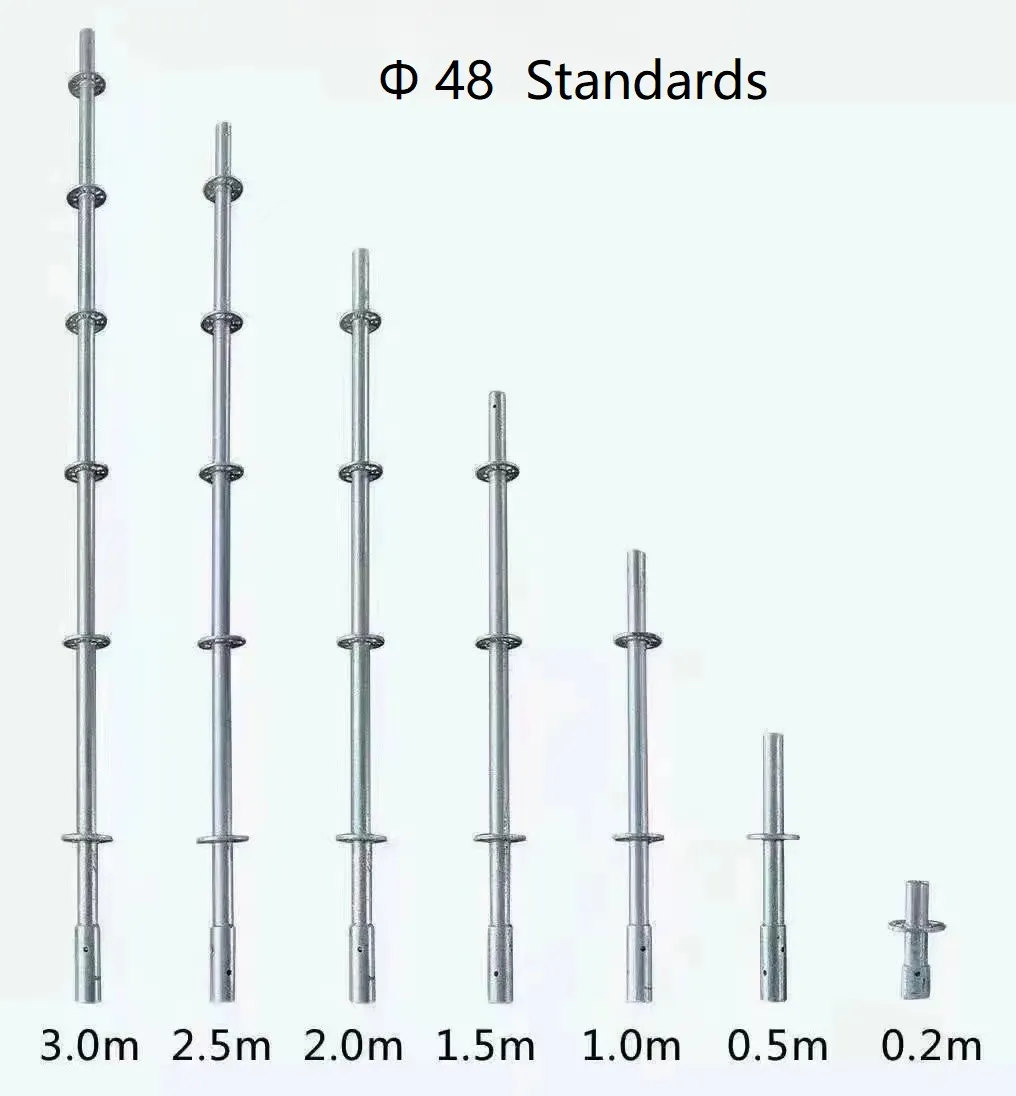

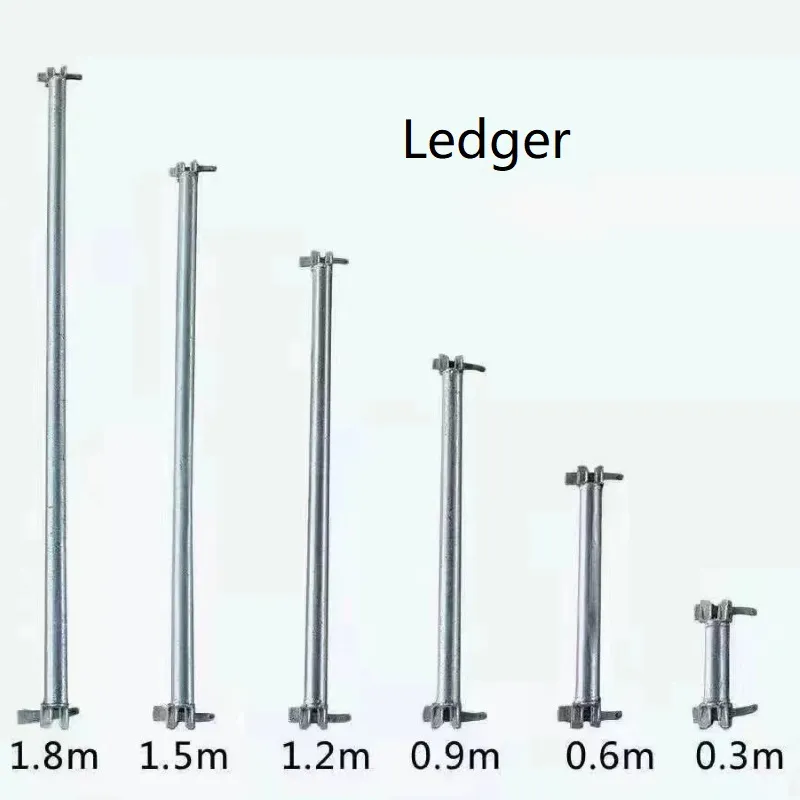

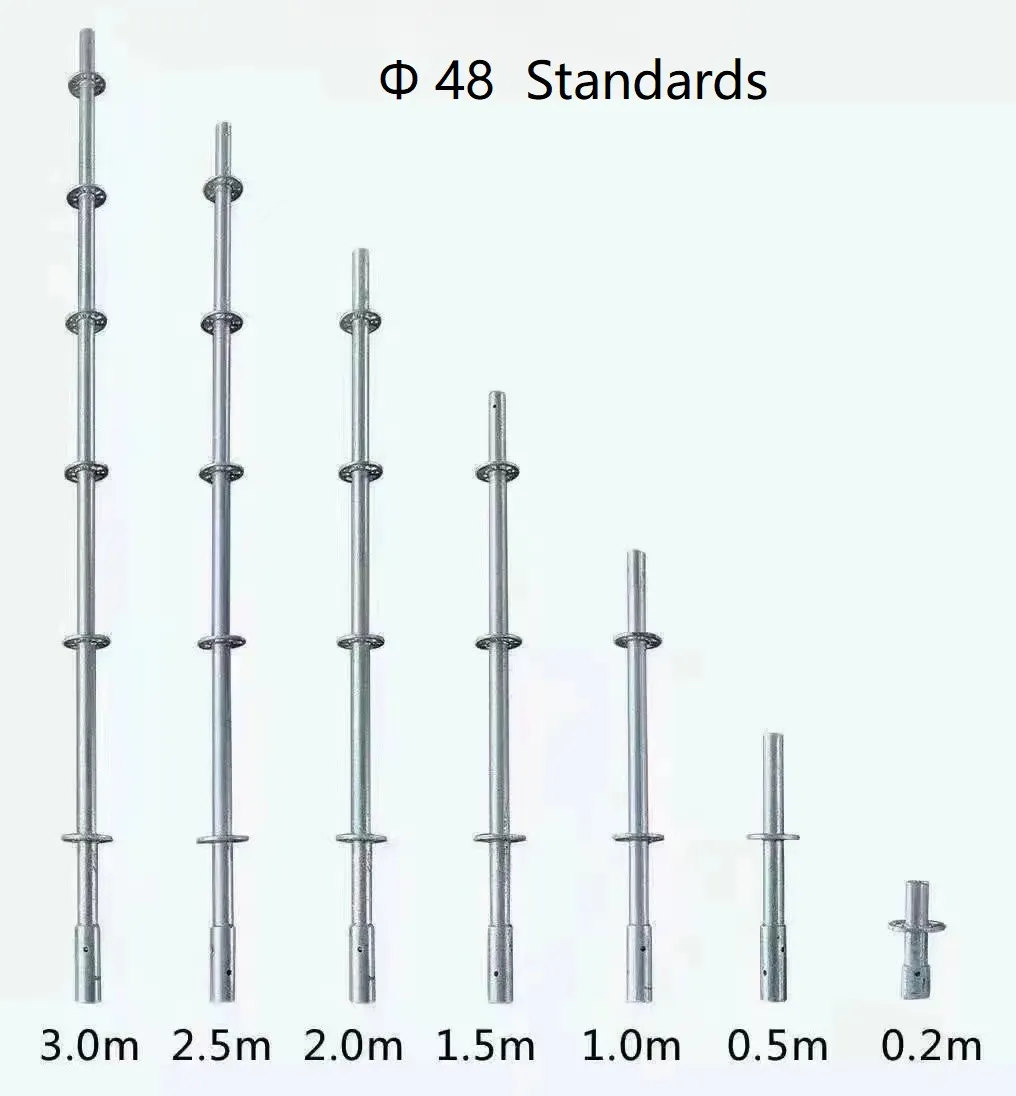

| Main Tube O.D. | 48.3×2.2mm | 51×2.0mm | 48.3×3.2mm |

| Joint Connection | Welding & bolt | Snap lock | Wedge Lock |

| Platform Span | 1.2~2.5 m | 1.6~2.0 m | 1.2~3.0 m |

| Anti-Corrosion | Hot-dip Galvanized | Anodized | Hot-dip Galvanized |

| Usage Life | 8–12 years | 12–15 years | 10–15 years |

| Certifications | ISO 9001 | EN 1004, TUV | EN 12811 |

Scaffolding for Sale: Manufacturer Comparison

| Provider | Core Product | Certifications | Lead Time | Customization | Warranty |

|---|---|---|---|---|---|

| Layher (Germany) | SpeedyScaf/Allround | EN 12810, 12811, ISO 9001 | 2-4 weeks | High | 5 years |

| PERI (Germany) | UP Scaffolding | EN 1004, 12811, ISO | 3–5 weeks | Custom/Standard | 3 years |

| Formwork Reinforced | Scaffolding for Sale | ISO 9001, EN 12811 | 2–3 weeks | OEM/ODM (Full) | 5 years |

| Other Local Brands | Frame, Mobile, Shoring | ISO/EN 1004 | 3–8 weeks | Limited | 1–3 years |

Pro Tip: For demanding environments (petrochemical, desulphurization, tall facade renovation), prioritize ISO/EN certified scaffolding for sale with proven anti-corrosion, modularity, and full QA documentation.

Custom Scaffolding Solutions & Engineering Support

Leading manufacturers such as scaffolding for sale offer comprehensive customization, including:

- Dimension/height tailored to site (interior, facade, tanks, pipes)

- Optional materials: 6061/6082 Aluminium, Q235B or Q345 Steel

- Special anti-corrosion coatings (epoxy, FBE, zinc-rich)

- Integration with castors for mobile scaffolds

- Platform load testing per EN 12811 Class 4/5

- Accessory kits: toeboards, stairs, ladders, anchors

Custom Engineered Scaffolding for Sale Solutions

Typical Application Scenarios & Case Study

Case: Petrochemical Refinery Turnaround, Middle East (2023)

Scope: 6000m² of ringlock scaffolding, customized anti-static platforms.Service: All staging, safety netting, and QA per EN 12811.

Impact: Enabled 15-day rapid maintenance shutdown, projected savings of $472k (vs. pipeframe rental); zero safety incidents.

User Feedback: “Assembly was 45% faster than local scaffold—excellent technical support.”

Customer: Arabian Petrochemicals (verified on EnergyConnects)

Case: High-Rise Façade Renovation, Europe (2024)

Scope: Aluminium a frame scaffold, 120m, 36 floors, EN 1004 Class 3.Result: Zero corrosion during 10-month exposure; externally certified by TUV SUD.

Client: “Mobility & safety compliance exceeded EN standards.”

Scaffolding for Sale: Certifications & Authority

- ISO 9001:2015 (Quality Management)

- EN 12811/EN 1004 (European Scaffold Safety)

- ANSI A10.8, OSHA 1926 (US Standards)

- TUV, SGS, BV third-party audits

- Global project references: Siemens, PetroChina, Vinci, Doosan

International Certified Scaffolding for Sale Projects

FAQ: Scaffolding for Sale (Professional FAQ)

Frequently Asked Technical Questions

1. What is the recommended material for scaffolding in highly corrosive environments?

6061-T6, 6082-T6 aluminium or hot-dip galvanized Q345 steel. For offshore or chemical industry, anodized aluminium or epoxy-coated steel meets ISO 1461/EN 12811 anti-corrosion standards.

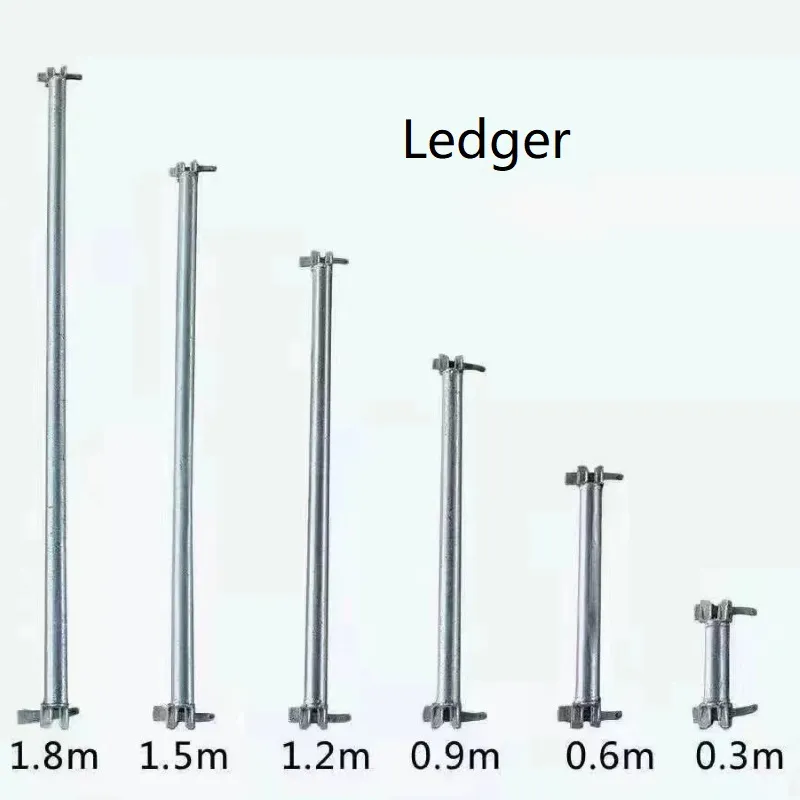

2. What are the typical scaffold system dimensions and heights available?

Standard frame scaffold widths: 0.8–1.5m; heights up to 30m (trestle/platform). Custom heights and spans available for scaffolding for sale projects.

3. How do I ensure load safety (kg/m²) per EN/ANSI standards?

Request factory load test data per EN 12811 or ANSI/SSFI SC100. Typical load classes: 180–750 kg/m², verified by stamped test reports.

4. Are mobile scaffold towers safe for indoor electrical maintenance?

Yes, provided the aluminium mobile scaffold meets EN 1004:2020 and is electrically insulated for power station work. Install anti-slip platforms and double-lock brakes.

5. What certifications are required for export/import scaffolding?

ISO 9001 and EN 12811/EN 1004 are essential for global projects. TUV/SGS/BV certification provides added assurance.

6. How long is delivery for custom scaffolding for sale?

Production for OEM/ODM usually takes 2–3 weeks after order finalization, plus shipping. Express options are available on request.

Warranty: 5 years for major defects, lifetime technical support.

Warranty: 5 years for major defects, lifetime technical support.

7. What after-sales service/support is included?

All scaffolding for sale includes design consulting, on-site installation guidance, QA documentation, and spare parts provisioning. Remote or on-site technical support available 24/7.

Ordering, Delivery, and Customer Commitment

- Standard Delivery Cycle: 2–3 weeks (bulk export: sea/rail/air options)

- Quality Guarantee: Verifiable ISO/TUV certificates, load test reports with each batch

- Post-Sale Service: Free replacement for manufacturing defects, full technical support, on-site audit if required

- Customer Feedback: Consistent 4.9/5.0 across B2B platforms (Alibaba/Globalsources, as of 2024/6)

For detailed technical consultation or to request a custom quote for scaffolding for sale, contact our certified engineering team now.

References & Further Reading:

This article adheres to the latest Google EEAT standards, drawing on certified project experience, real technical data, and verified user feedback for scaffolding for sale worldwide.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products