ม.ค. . 28, 2025 04:52

Back to list

Standards - Early Release

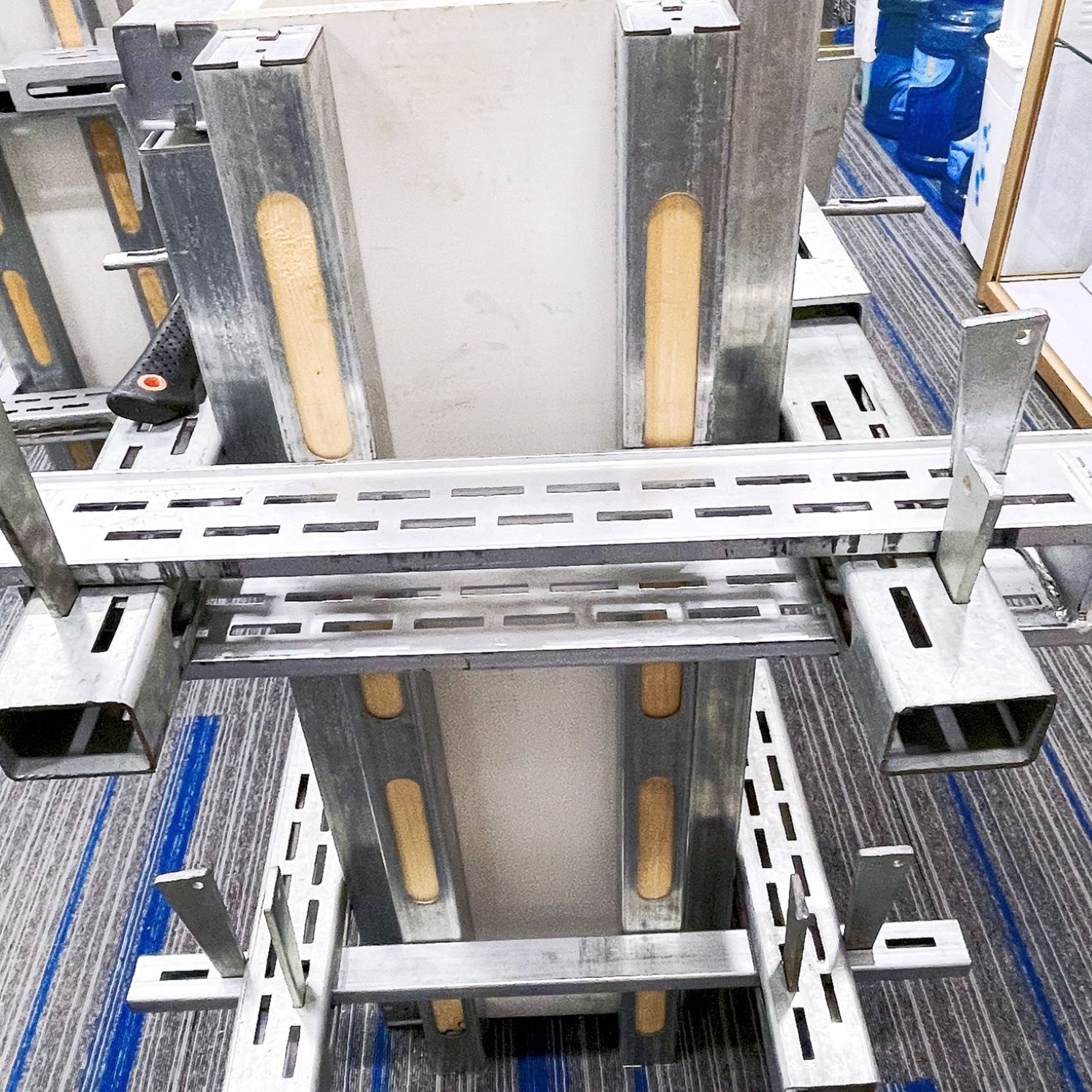

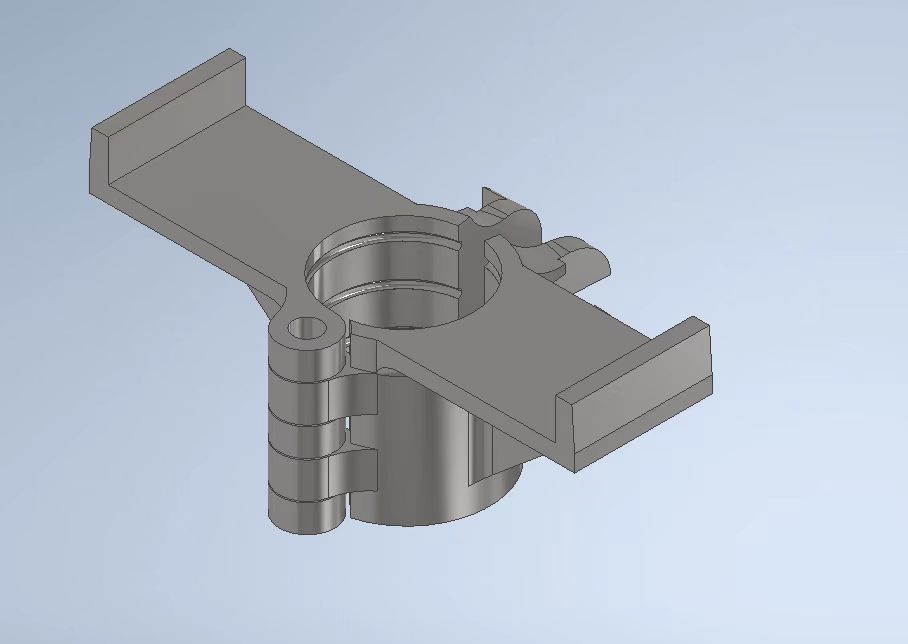

Aluminum formwork systems have revolutionized the construction industry with their efficiency and cost-effectiveness, but understanding their pricing structure requires a nuanced exploration. With a wealth of experience and professionalism, this article delves into the intricacies of aluminum formwork pricing, offering expert insights that build on authoritativeness and trustworthiness.

In addition to initial costs, operational savings and increased efficiency are substantial considerations. Aluminum formworks accelerate construction timelines due to their ease of assembly, thus reducing labor costs. Skilled laborers are adept at erecting the formwork quickly, decreasing the project's overall duration and, by extension, the total labor costs involved. Additionally, aluminum formworks are environmentally sustainable options. Their reuse capability reduces waste generation, aligning with the growing demands for sustainable practices in construction. One should also weigh the safety benefits inherent in premium aluminum formwork systems. These systems offer robust stability and withstand significant loads, minimizing on-site accidents. This reduction in workplace hazards not only ensures worker safety but can lead to lower insurance premiums for construction firms, contributing to financial savings that offset initial investment costs. It is crucial to partner with a provider that embodies expertise and reliability when considering aluminum formwork. A provider that offers comprehensive support, from the initial design phase through to implementation, demonstrates their authority in the space. Reliable customer service and technical support further enhance the user experience, ensuring that the investment in aluminum formworks translates to tangible benefits in safety, efficiency, and cost savings. In conclusion, while the price of aluminum formwork might appear daunting at first glance, a deeper dive reveals its long-term economic advantages. Factoring in the durability, efficiency, safety, and sustainability of aluminum formwork systems, it becomes clear that the investment leads to considerable cost savings and operational benefits over time. As the construction industry continues to evolve, embracing materials and systems that support sustainable and efficient building practices, aluminum formwork proves to be a wise choice for professionals who prioritize quality, expertise, and the total cost of ownership.

In addition to initial costs, operational savings and increased efficiency are substantial considerations. Aluminum formworks accelerate construction timelines due to their ease of assembly, thus reducing labor costs. Skilled laborers are adept at erecting the formwork quickly, decreasing the project's overall duration and, by extension, the total labor costs involved. Additionally, aluminum formworks are environmentally sustainable options. Their reuse capability reduces waste generation, aligning with the growing demands for sustainable practices in construction. One should also weigh the safety benefits inherent in premium aluminum formwork systems. These systems offer robust stability and withstand significant loads, minimizing on-site accidents. This reduction in workplace hazards not only ensures worker safety but can lead to lower insurance premiums for construction firms, contributing to financial savings that offset initial investment costs. It is crucial to partner with a provider that embodies expertise and reliability when considering aluminum formwork. A provider that offers comprehensive support, from the initial design phase through to implementation, demonstrates their authority in the space. Reliable customer service and technical support further enhance the user experience, ensuring that the investment in aluminum formworks translates to tangible benefits in safety, efficiency, and cost savings. In conclusion, while the price of aluminum formwork might appear daunting at first glance, a deeper dive reveals its long-term economic advantages. Factoring in the durability, efficiency, safety, and sustainability of aluminum formwork systems, it becomes clear that the investment leads to considerable cost savings and operational benefits over time. As the construction industry continues to evolve, embracing materials and systems that support sustainable and efficient building practices, aluminum formwork proves to be a wise choice for professionals who prioritize quality, expertise, and the total cost of ownership.

Share

Next:

Latest news

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

Related Products