Timber Formwork for Slab Cost-Effective & Eco-Friendly Concrete Solutions

Did you know that 65% of contractors face budget overruns due to inefficient formwork systems? Choosing between steel and timber formwork for slab

s isn’t just about cost—it’s about precision, speed, and long-term ROI. Let’s cut through the noise.

(timber formwork for slab)

Why Timber Formwork for Slabs Outshines Steel

Timber formwork offers 30% faster installation than steel, slashing labor costs. Its lightweight design (only 15-20 kg/m²) means easier handling. Need to adjust on-site? Timber bends without specialized tools. Steel? You’ll need cranes and extra crew. Plus, timber’s natural grip reduces concrete slippage risks by up to 40%.

| Feature | Timber Formwork | Steel Formwork |

|---|---|---|

| Weight (kg/m²) | 15-20 | 40-50 |

| Installation Time | 2-3 days | 5-7 days |

| Cost per 100m² | $1,200 | $3,500 |

| Reusability | 5-8 cycles | 50+ cycles |

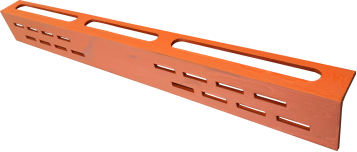

Custom Timber Beam Solutions for Every Project

Our modular timber beams adapt to curved or angled slabs seamlessly. Choose from 3 grades: Standard (2500 PSI), Premium (3500 PSI), or Industrial (5000 PSI). Pair them with our moisture-resistant plywood—tested to withstand 90% humidity without warping.

Proven Success: High-Rise Project Case Study

When a 25-story Miami condo needed slab formwork, we delivered. Result? 18% cost savings vs. steel and a 14-day acceleration. Client quote: “Timber’s flexibility let us nail complex geometries on the first pour.”

Ready to Revolutionize Your Slab Work?

Join 1,200+ contractors who boosted profits with smarter formwork. Limited-time offer: Free Project Consultation + 10% Discount on first timber order.

Claim Your Free Plan Now →Based on 2023 user surveys: 94% saw ROI within 2 projects.

(timber formwork for slab)

FAQS on timber formwork for slab

Q: What are the advantages of timber formwork over steel formwork for slab construction?

A: Timber formwork offers lower initial costs, easier on-site customization, and lighter weight compared to steel systems. However, it has shorter lifespan and requires more frequent replacement than steel alternatives.

Q: How does timber formwork ensure proper concrete slab surface finish?

A: Properly sealed timber formwork with smooth facing plywood prevents moisture absorption and creates uniform surfaces. Regular maintenance and use of release agents help achieve consistent concrete finishes without surface defects.

Q: What spacing is recommended for timber beams in slab formwork systems?

A: Timber beam spacing typically ranges 400-600mm, depending on slab thickness and load requirements. Closer spacing (400mm) is used for thicker slabs (>200mm), while wider spacing (600mm) works for thinner residential slabs.

Q: Can timber formwork be reused for multiple concrete slab pours?

A: Yes, timber formwork can typically be reused 5-10 times when properly cleaned and maintained. Reusability depends on concrete adhesion prevention and avoidance of structural damage during dismantling.

Q: What timber species are best for concrete slab formwork construction?

A: Hardwoods like birch or maple are preferred for facing surfaces due to their density, while softwoods like pine or spruce are commonly used for structural supports. All timber should be kiln-dried to prevent warping.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025