Фев . 16, 2025 00:28

Back to list

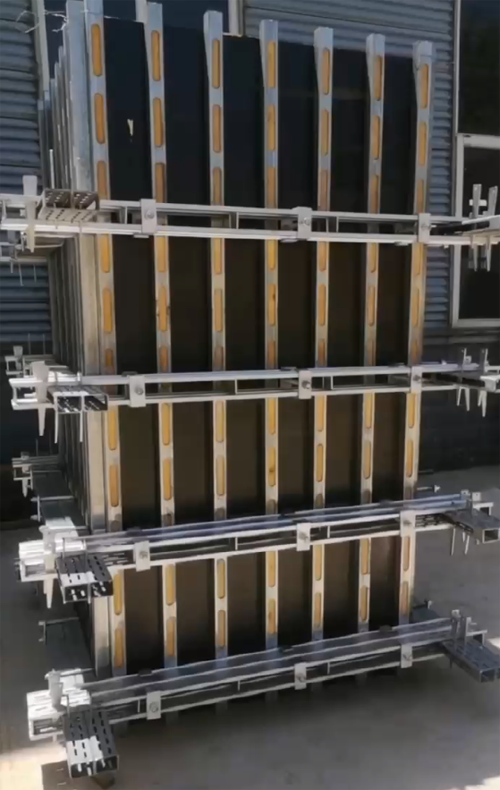

Scaffolding

The scaffold sleeve coupler is a pivotal component in the world of construction and industrial projects, representing a cornerstone of safety and reliability. In an era where efficiency and worker safety are of utmost importance, understanding the role and benefits of scaffold sleeve couplers becomes essential for professionals in the construction industry.

Trustworthiness in scaffold sleeve couplers is closely linked to their testing and certification. Reputable manufacturers subject their products to rigorous testing environments that simulate real-world conditions. This includes fatigue tests, extreme weather exposure, and load-bearing assessments. The results are often verified by third-party organizations, providing an additional layer of trust. When contractors and builders opt for couplers with recognized certifications, they signal a commitment to safety and quality, which resonates across all project stakeholders. In addition, the evolving landscape of construction technology has prompted advancements in the design and functionality of scaffold sleeve couplers. Innovations such as anti-corrosion coatings and precision-engineered locking mechanisms have made these components more reliable than ever before. These improvements not only extend the lifespan of the couplers but also enhance the overall efficiency of scaffold assembly and disassembly. Understanding the nuances of scaffold sleeve couplers empowers construction professionals to make informed decisions. When utilized correctly, these components significantly mitigate risks associated with scaffolding failures. They also represent an investment in long-term safety outcomes, reducing the incidence of accidents and injuries on site. Whether dealing with residential, commercial, or industrial projects, the reliable performance of scaffold sleeve couplers remains a non-negotiable aspect of construction management. With a deep reliance on these essential merging devices, leaders in construction find confidence in their projects’ structural integrity and the safety of their workforce. The scaffold sleeve coupler, a seemingly simple yet complex component, operates at the heart of one of the most demanding and dynamic industries. By prioritizing quality, compliance, and ongoing education concerning these critical tools, construction experts are better equipped to tackle the challenges of modern building endeavors.

Trustworthiness in scaffold sleeve couplers is closely linked to their testing and certification. Reputable manufacturers subject their products to rigorous testing environments that simulate real-world conditions. This includes fatigue tests, extreme weather exposure, and load-bearing assessments. The results are often verified by third-party organizations, providing an additional layer of trust. When contractors and builders opt for couplers with recognized certifications, they signal a commitment to safety and quality, which resonates across all project stakeholders. In addition, the evolving landscape of construction technology has prompted advancements in the design and functionality of scaffold sleeve couplers. Innovations such as anti-corrosion coatings and precision-engineered locking mechanisms have made these components more reliable than ever before. These improvements not only extend the lifespan of the couplers but also enhance the overall efficiency of scaffold assembly and disassembly. Understanding the nuances of scaffold sleeve couplers empowers construction professionals to make informed decisions. When utilized correctly, these components significantly mitigate risks associated with scaffolding failures. They also represent an investment in long-term safety outcomes, reducing the incidence of accidents and injuries on site. Whether dealing with residential, commercial, or industrial projects, the reliable performance of scaffold sleeve couplers remains a non-negotiable aspect of construction management. With a deep reliance on these essential merging devices, leaders in construction find confidence in their projects’ structural integrity and the safety of their workforce. The scaffold sleeve coupler, a seemingly simple yet complex component, operates at the heart of one of the most demanding and dynamic industries. By prioritizing quality, compliance, and ongoing education concerning these critical tools, construction experts are better equipped to tackle the challenges of modern building endeavors.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products