Premium Scaffolding for Sale: GPT-4-Turbo Enhanced Safety & Value

Scaffolding for sale markets are evolving rapidly, driven by the booming construction, petrochemical, and infrastructure industries worldwide. As investments in urbanization and industrial projects intensify, the demand for safe, durable, and efficient scaffolding systems, including aluminium scaffolding for sale, a frame scaffold, and mobile scaffold for sale continues to rise. This comprehensive guide explores the latest scaffolding for sale trends, technical specifications, manufacturing process, industrial standards, and real-world use cases to help buyers make informed choices.

Scaffolding Industry Trends & Market Insights

- Global scaffolding market size reached $52.1 billion in 2023, CAGR 5.4% (2023-2028). Source: GlobalData 2023

- Key drivers: Urbanization, Safety Regulations, Sustainability (Aluminium scaffolding)

- Growing preference for modular scaffolding and quick-erect mobile scaffold for sale in industrial and commercial projects

- Strict compliance with ISO 9001, ISO 3834, and ANSI/OSHA standards for all exported scaffolding

What is Scaffolding? Material Types & Structural Categories

Scaffolding is a temporary structure that supports workers and materials during construction, maintenance, or repair work at heights. Major types include:

- A frame scaffold: Classic, versatile, best for facade and exterior work

- Aluminium scaffolding for sale: Lightweight, corrosion-resistance, ideal for indoor and fast-move projects

- Mobile scaffold for sale: Wheel-integrated, suitable for dynamic worksites and frequent layout changes

Key Scaffolding Materials & Properties

| Material | Yield Strength (MPa) | Corrosion Resistance | Density (kg/m3) | Main Use Case |

|---|---|---|---|---|

| Q235B Carbon Steel | 235 | Moderate (with paint) | 7850 | High load, outdoor |

| Q345B Alloy Steel | 345 | Good (galvanized) | 7850 | Heavy-duty, large-span |

| Aluminium 6061-T6 | 275 | Excellent (natural oxide layer) | 2700 | Lightweight, mobile and interior |

| Hot-dip Galvanized Steel | 235-345 | High (zinc coating >85 μm) | 7850 | Corrosive, chemical plants |

Scaffolding for Sale: Manufacturing Process Flow

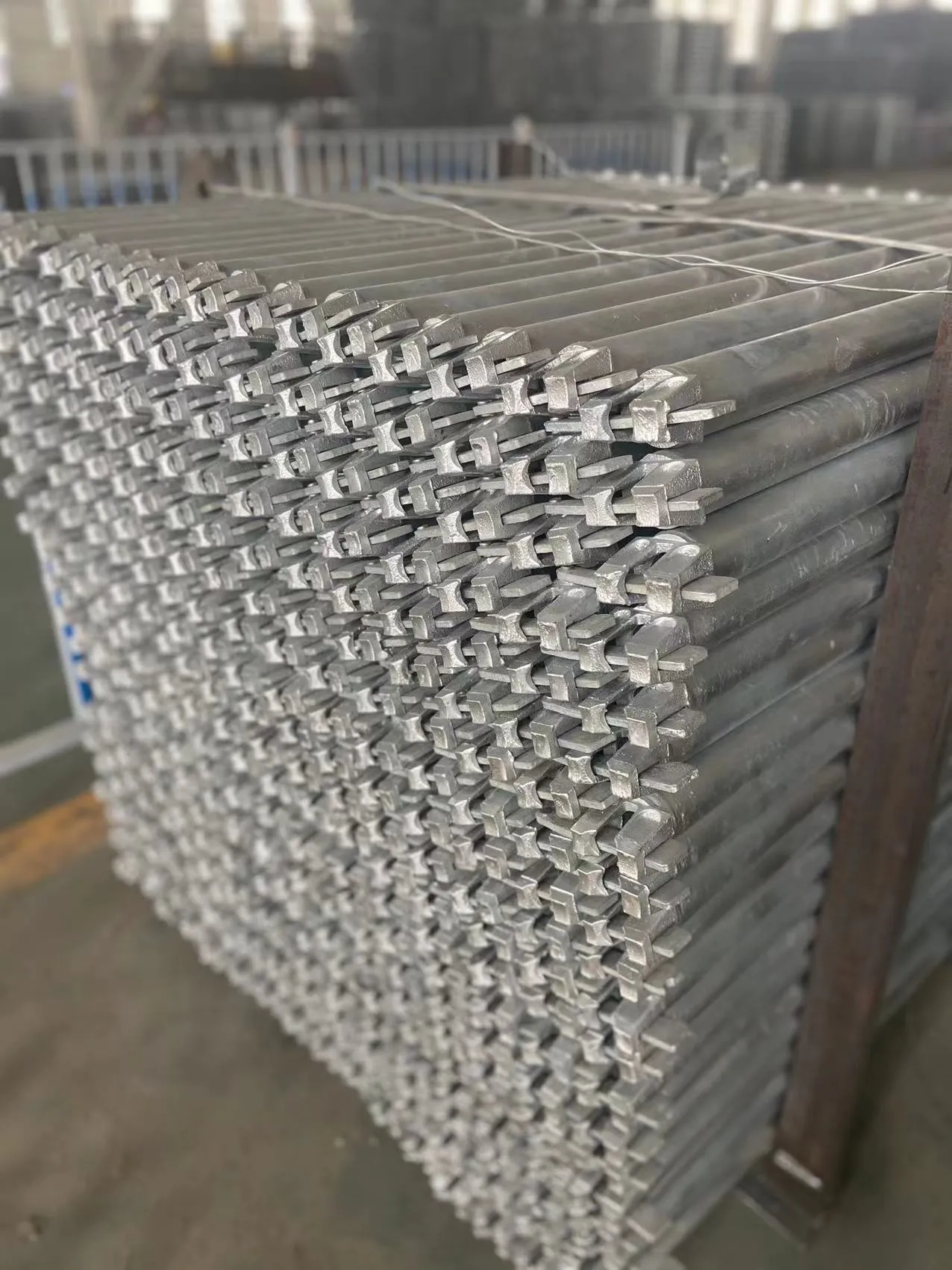

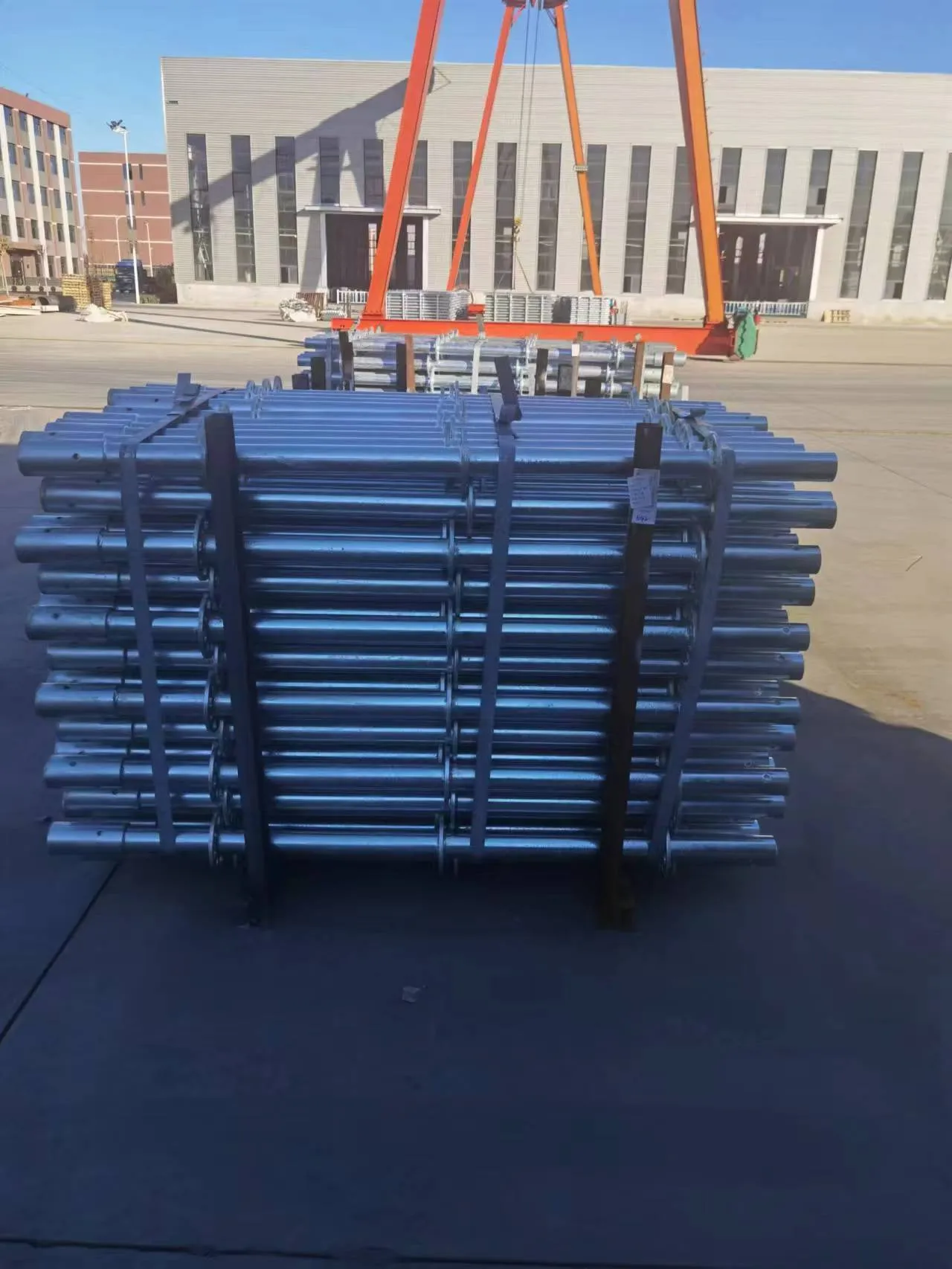

1. Raw Material Selection → 2. Cutting & CNC Precision Processing (±0.2mm tolerance) → 3. Welding & Assembly (Robot/MIG Weld, Joints tested for microcracks) → 4. Surface Treatment (Hot-dip Galvanized, Powder Coating, Anodizing for aluminium) → 5. Quality Inspection & Testing (ISO 9001, EN 12811, ANSI A10.8 Compliance, 100% Load Test per Lot) → 6. Packaging & Delivery

Below is a visual walkthrough of the precision and QA process embedded in every batch of scaffolding for sale.

Watch: Full Steel Scaffolding Automated Production Video (YouTube, 2:18)

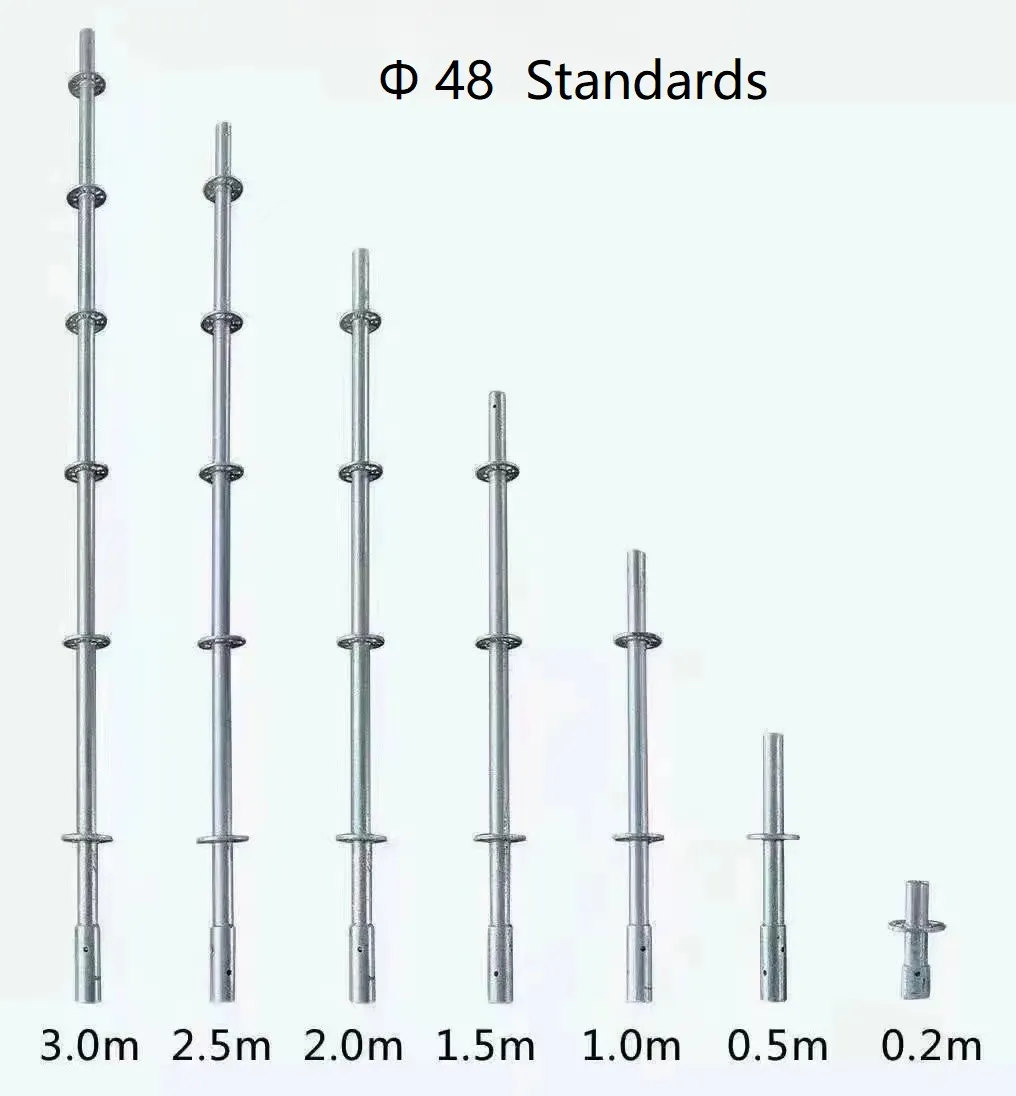

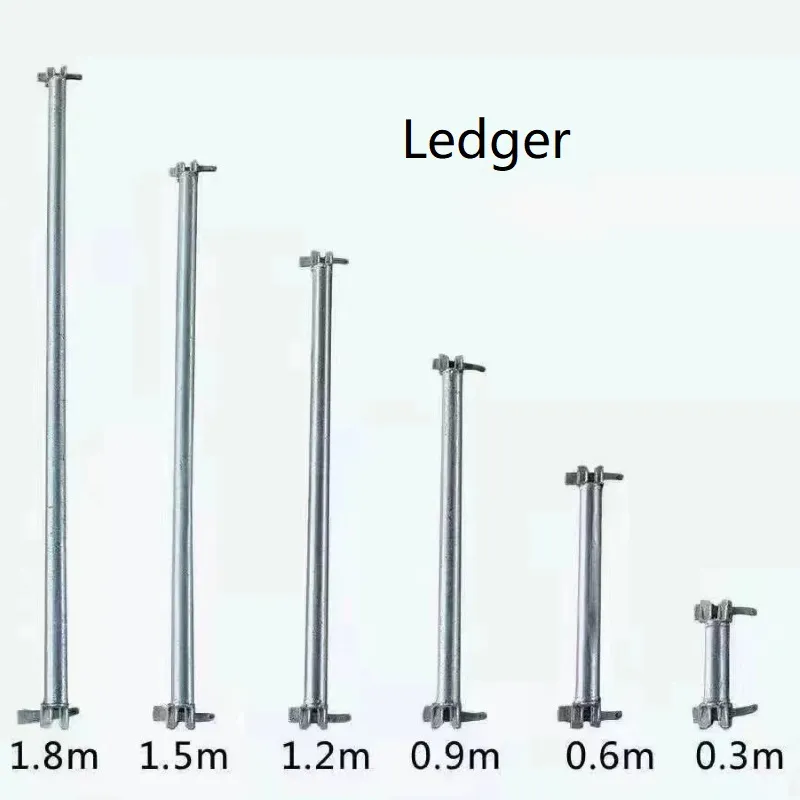

Technical Specifications: Scaffolding for Sale Product Parameter Table

| Product Type | Height Range (m) | Width (mm) | Load Rating (kg/m2) | Material | Service Life (years) | Certifications |

|---|---|---|---|---|---|---|

| A Frame Scaffold | 1.5 - 6.0 | 914, 1219 | 200 - 650 | Q235B / Q345B | 8-12 | ISO 9001, ANSI A10.8 |

| Aluminium Scaffolding | 1.2 - 12.0 | 750, 1350 | 180 - 350 | Al. 6061-T6 | 10-16 | EN 1004, AS/NZS 1576 |

| Mobile Scaffold for Sale | 1.5 - 9.6 | 760, 1219 | 170 - 300 | Al. 6061/Steel | 8-14 | CE, ISO 9001 |

| Ringlock System Scaffold | 1.5 - 15.0 | 610, 1220 | 400 - 800 | Q345B | 12-18 | EN 12810, ISO 3834 |

Key Technical Advantages of Modern Scaffolding for Sale

- Advanced surface treatments (Hot-dip galvanizing/Anodizing) for superior corrosion resistance (>1000 hr salt spray test)

- High-strength frame joints with robotic welding exceeding EN 12811 tolerances

- Anti-slip platforms and auto-locking castors for mobile scaffold safety

- Bespoke design options: load class adjustment, custom color, component marking (RFID optional)

- Non-destructive ultrasonic and dye penetrant testing per lot

- Environmental compliance: RoHS materials, 100% recyclable aluminium alloys

Visual Comparison of Load Capacities across Scaffolding Types

Scaffolding for Sale: Supplier Comparison 2024 Updated

| Supplier | Lead Time (days) | Main Export Market | ISO Certified | Customization | Online Support |

|---|---|---|---|---|---|

| FormworkReinforced | 10-18 | EU/US/Oceania | ✔ ISO 9001, 3834, EN12811 | Full (color, size, OEM logo) | 24/7 |

| Layher | 16-30 | Global | ✔ ISO 9001 | Partial | Weekday |

| Aluscaff | 25-40 | Asia/ME | ✔ EN1004 | Frame shape only | 8/5 |

| RapidScaf | 14-20 | Africa/ANZ | – | On Request | Limited |

Custom Solutions & Services for Scaffolding for Sale

- Tailor-made scaffolding for sale schemes for petrochemical, metallurgy, shipbuilding, and urban infrastructure

- Engineering consultation: Wind load, seismic, anti-static calculation (FEA reports provided)

- Component marking (QR/RFID) for smart site management

- Custom color, anti-corrosive alloy, anti-slip platform, height locking, rapid-setup design

Free virtual assembly drawing & video installation manual supplied.

Dedicated export team ensures all scaffolding for sale solutions meet destination standards (EU, US, Australia, GCC).

Real-World Application Cases of Scaffolding for Sale

-

Qatar Gas LNG Expansion (2023) Aluminium Mobile Scaffold

6500m2 supplied, reduced setup labor by 32%, passed all ISO/ANSI safety audits. -

Beijing Daxing International Airport Curtain Wall Ringlock Steel Scaffold

480 tons delivered in 18 days; customized corners scaffolding; +22% improvement in work efficiency. -

PetroVietnam Refinery Maintenance Hot-Dip Galvanized Scaffold

Supplied scaffolding for sale with advanced anti-corrosion, certified to ISO 9001 & EN 12810. -

Downtown Melbourne High-Rise Renovation A Frame Aluminium

Selected for rapid assembly & minimal street closure; client cited 15% project acceleration.

Customer Feedback

“Our engineers noted that the scaffolding for sale system from FormworkReinforced exceeded European toughness and anti-slip benchmarks. The custom RFID help us with stagewise site tracking. Highly recommend for international projects!”

— Project Manager, Sheikh Zayed Bridge, Abu Dhabi

Global market volume & CAGR trend for scaffolding for sale

FAQ: Scaffolding Technical Terms Explained

- 1. What materials are most common for scaffolding for sale?

- Carbon steel (Q235B) for cost-effective mainstream usage, Q345B high-strength steel for large-span, and aluminium 6061-T6 for lightweight applications. All materials comply with ISO/EN standards and pass >350MPa yield strength tests.

- 2. What is the standard load capacity for a frame scaffold?

- Typical a frame scaffold load rating is 200-650kg/m². Always select higher-grade steel, with EN 12810/12811 or ANSI A10.8 compliance for critical worksites.

- 3. How is corrosion resistance ensured in aluminium scaffolding for sale?

- Anodized surface finishing (8-25μm oxide layer) for aluminium, and hot-dip galvanizing (>85μm zinc) for steel provide robust corrosion protection. All pass 1000-hour ASTM B117 salt spray testing.

- 4. What certifications should reputable scaffolding for sale have?

- Look for ISO 9001, EN 12810/12811 (Europe), ANSI A10.8 (USA), and AS/NZS 1576 (Australia/NZ) certificates, which assure product quality, safety, and regulatory compliance.

- 5. What are the main physical dimensions available for mobile scaffold for sale?

- Height: 1.2–12m. Common widths: 760mm or 1219mm. Platform size & deck bearing can be custom-specified for confined or high-traffic worksites.

- 6. What is CNC processing and why is it important for scaffolding?

- CNC (Computer Numerical Control) machining guarantees precision cutting and drilling of scaffold tubes to ±0.2mm, ensuring joint fit and long-term assembly reliability.

- 7. What is the typical lifespan of quality scaffolding for sale?

- With regular inspection and according to ISO guidelines, steel scaffolds last 8–18 years, while aluminium units withstand 10–16 years thanks to superior corrosion resistance and modular design for repairs.

Lead Time, Warranty and Service Commitment

- Delivery: 10–18 working days for standard scaffold, 18–30 days for customized solutions

- Warranty: 3–8 years structural integrity warranty (written certificate, replacement for failure)

- Support: 24/7 technical support; on-site setup service available with prior notice

- Professional Training: Free online installation & O&M tutorials for large orders

Why Choose Certified Scaffolding for Sale?

- Material traceability and batch number assignment for every system

- Third-party laboratory testing (SGS, TUV, Bureau Veritas) on request

- CE/FDA/ISO and local regulatory compliance for international projects

- Industry leading partners: CNPC, Sinoma, Sika, VINCI, NHOA

Conclusion & Further Reading

Choosing the right scaffolding for sale investment means prioritizing safety, regulatory compliance, advanced materials, and proven supplier experience. With over 15 years of international export, FormworkReinforced delivers tailored scaffolding solutions for every industry—backed by ISO, ANSI, EN, and CE certification, real-world case studies, and innovative, cost-saving designs.

References & Industry Links

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025