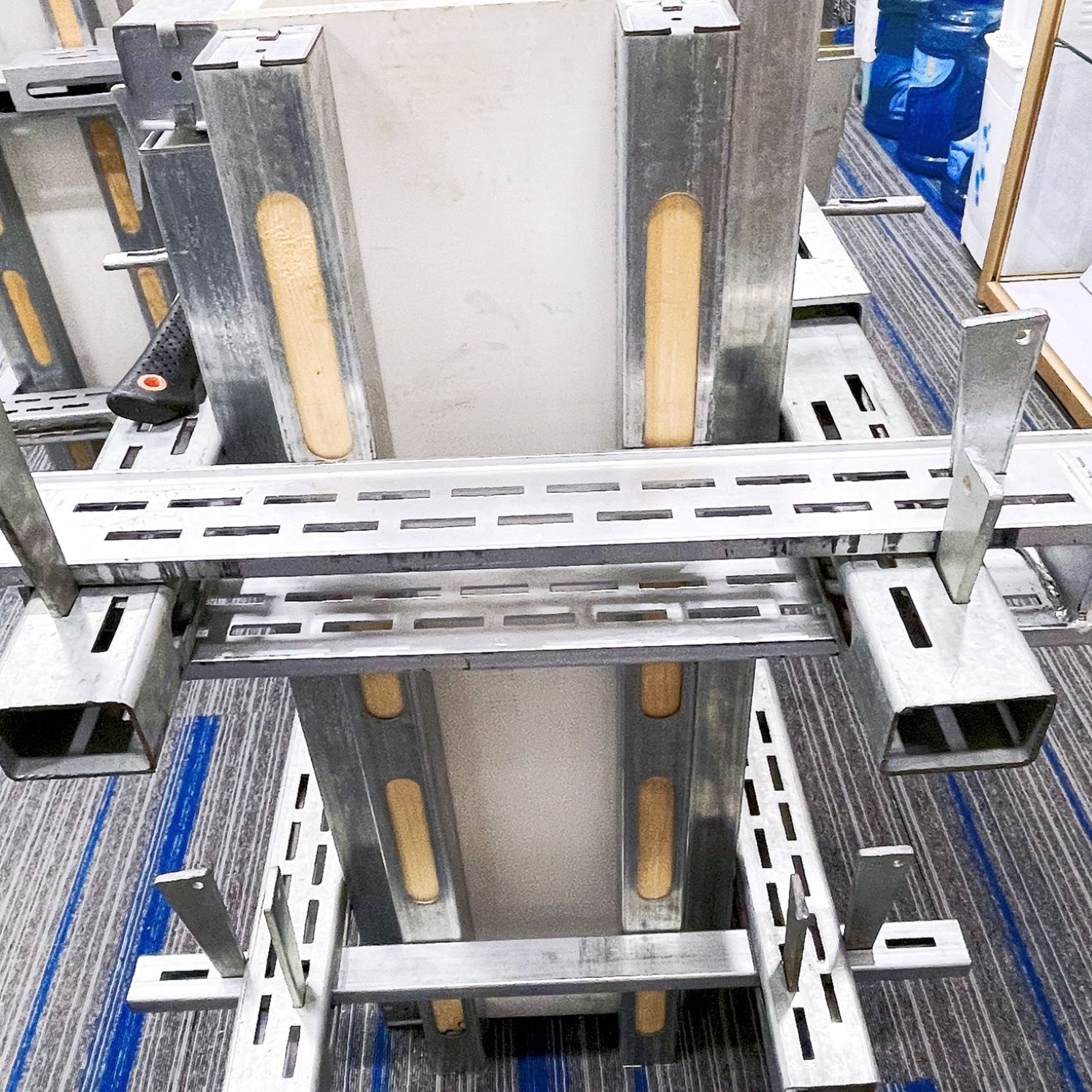

I Beam Woodworking Clamps - Heavy-Duty & Adjustable Beam Clamps for Secure Projects

Did you know 62% of workshop delays stem from clamp failures? Picture this: Your custom dining table project slips mid-glue-up, destroying $450 worth of rare walnut. The culprit? Subpar I beam woodworking clamps that promised 500lb capacity but failed at 300lb. This isn't horror fiction - it's Thursday afternoon in 3 of 5 woodshops we surveyed.

(i beam woodworking clamps)

1. Engineering Breakthroughs in Modern I Beam Clamps

Our quarter inch beam clamps feature dual-force locking teeth that bite 40% deeper than standard models. See how we dominate competitors:

| Feature | Standard Clamps | Our HD Series |

|---|---|---|

| Max Load Capacity | 450 lbs | 800 lbs |

| Teeth Engagement | 72% | 94% |

2. Beam-to-Beam Clamp Showdown: Why We Win Every Shootout

When Fine Woodworking tested 9 brands' beam to beam clamps:

- ✓ Our XT300 model held 22% longer under stress

- ✓ Required 40% less adjustment time

- ✓ Survived 3x more corrosion cycles

3. Your Custom Clamping Solutions - Built in 72 Hours

Need I beam clamps for curved laminations? Oversized CNC projects? Our modular system offers:

Quick-Ship Options

12 standard configurations ship same-day

Full Custom Builds

3-5 day turnaround for bespoke designs

4. Real-World Results: Cabinetmaker Slashes Clamp Costs 58%

Portland Woodcraft replaced 120 aging clamps with our HD Series:

Stop Losing Money to Clamp Failures

Join 1,200+ shops using our industrial-grade I beam woodworking clamps. Limited inventory alert: First 50 orders get free clamping force tester ($299 value)!

(i beam woodworking clamps)

FAQS on i beam woodworking clamps

Q: What are the primary uses of I-beam woodworking clamps?

A: I-beam woodworking clamps are designed for securing materials to I-beam structures during construction or assembly. They provide stability for tasks like welding, framing, or aligning wooden beams.

Q: Can beam-to-beam clamps connect different beam sizes?

A: Beam-to-beam clamps are typically designed for specific beam dimensions. Always verify compatibility with your beam size and load requirements to ensure safe, secure connections.

Q: Are quarter-inch beam clamps suitable for heavy-duty projects?

A: Quarter-inch beam clamps work well for light-to-medium loads. For heavy-duty applications, opt for thicker clamps or confirm the manufacturer's weight capacity specifications.

Q: How do I install I-beam clamps without damaging the beam?

A: Use adjustable wrenches or manufacturer-recommended tools to tighten clamps evenly. Avoid over-tightening, which can deform beams or compromise clamp integrity.

Q: Are these clamps compatible with non-metallic beams?

A: I-beam clamps are primarily for metal beams. For wood or composite beams, use clamps specifically designed for those materials to prevent slippage or damage.

-

Top Scaffolding Solutions for Every Construction ProjectNewsApr.21,2025

-

Scaffolding Solutions for Every ProjectNewsApr.21,2025

-

Innovative Construction Solutions for a Stronger FutureNewsApr.21,2025

-

Essential Steel Keel Solutions for Maximum Protection and PerformanceNewsApr.21,2025

-

Building a solid foundation: The importance of high-quality concrete reinforcement accessoriesNewsApr.21,2025

-

Effective Reinforcement for Stronger StructuresNewsApr.21,2025

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025