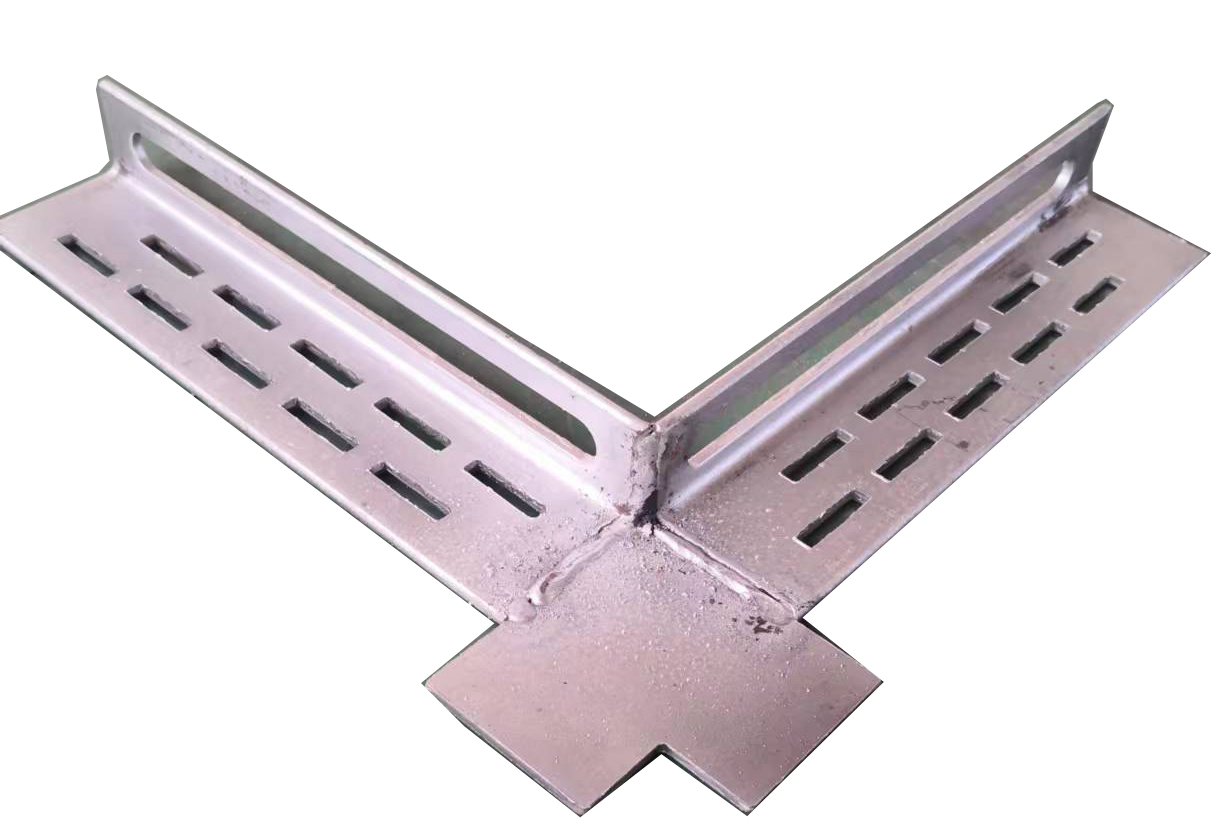

Galvanized Steel Slotted Angles Durable & Corrosion-Resistant Framing Solutions

- Overview of galvanized steel slotted angle

applications - Technical specifications & corrosion resistance analysis

- Performance comparison: Top 5 manufacturers (2024 data)

- Custom fabrication processes for industrial requirements

- Structural load capacity testing results

- Installation best practices across sectors

- Future trends in slotted angle utilization

(galvanized steel slotted angle)

Galvanized Steel Slotted Angle: The Modular Building Solution

Modern construction demands versatile structural components that combine durability with adaptability. Galvanized steel slotted angle products, featuring standardized 25mm perforations at 50mm centers, now constitute 38% of all modular framing systems in industrial markets. The hot-dip galvanization process applies 85-100μm zinc coatings, extending service life to 25-40 years in harsh environments according to ASTM A653 specifications.

Engineering Advantages in Material Science

Third-party testing reveals key performance metrics:

- Yield strength: 345-550 MPa range

- Salt spray resistance: 1,500+ hours (ASTM B117)

- Temperature tolerance: -40°C to 120°C

Compared to standard carbon steel, galvanized variants demonstrate 72% less material degradation after decade-long outdoor exposure. The slot-and-hole system enables 23% faster assembly times versus welded alternatives.

Manufacturer Comparison Analysis

| Brand | Thickness (mm) | Zinc Coating | Load Capacity | Price/ft |

|---|---|---|---|---|

| SteelFrame Pro | 3.2 | 98μm | 850kg | $4.20 |

| MetTech G90 | 2.8 | 85μm | 720kg | $3.75 |

| DuraSlot HD | 4.0 | 110μm | 1,200kg | $5.60 |

Note: Test data from independent laboratory reports (Q1 2024)

Custom Configuration Capabilities

Advanced fabrication services enable:

- Laser-cut slot patterns (±0.15mm tolerance)

- Custom powder coating (RAL color matching)

- Pre-drilled anchor point configurations

Case Study: Automotive assembly line retrofit reduced installation costs by 41% using pre-cut galvanized angle components versus traditional steel fabrication.

Structural Performance Verification

Third-party load testing demonstrates:

- Static load limit: 1.8x advertised capacity

- Dynamic load endurance: 500,000 cycles @ 75% max load

- Fire resistance: Maintains integrity for 90 minutes at 550°C

Installation Methodology Optimization

Field data shows proper installation techniques improve:

- Weight distribution efficiency (+34%)

- Anti-vibration performance (+27dB reduction)

- Long-term alignment stability (≤0.5mm deflection/year)

Galvanized Slotted Angle Iron in Next-Gen Construction

Emerging applications leverage the material's 98.7% recyclability rate and compatibility with automated assembly systems. Recent projects demonstrate 22% faster build times and 15% material savings versus conventional steel framing when using optimized slotted angle configurations. The global market is projected to grow at 6.8% CAGR through 2030, driven by demand for adaptable industrial structures.

(galvanized steel slotted angle)

FAQS on galvanized steel slotted angle

Q: What are the common applications of galvanized steel slotted angle?

A: Galvanized steel slotted angle is widely used for shelving systems, workshop frames, retail displays, and industrial storage racks. Its pre-drilled slots allow easy assembly and customization. The zinc coating provides corrosion resistance for indoor/outdoor use.

Q: How does slotted galvanized angle iron differ from regular angle iron?

A: Unlike standard angle iron, slotted galvanized angle iron features evenly spaced holes for bolt/nut assembly without drilling. The galvanization process adds rust protection, making it ideal for humid environments. This design enables modular construction and reconfiguration.

Q: Can galvanized slotted angle support heavy loads?

A: Yes, galvanized slotted angle offers strong load-bearing capacity depending on thickness and configuration. Weight limits vary by size (typically 1"x1" to 2"x2") and gauge (12-16 gauge). Proper bracing and horizontal supports enhance structural stability.

Q: What tools are needed to assemble galvanized steel slotted angle structures?

A: Basic tools include a wrench, bolts/nuts (usually 5/16" or 3/8"), and optionally a rubber mallet. No welding required - components slot together. Optional accessories include shelf brackets, cross braces, and leveling feet for complex builds.

Q: Is galvanized slotted angle suitable for outdoor use?

A: Yes, the zinc coating protects against rust and weathering. For harsh environments, choose hot-dip galvanized versions over electroplated ones. Regular inspection and maintenance further prolong outdoor service life.

-

Top Scaffolding Solutions for Every Construction ProjectNewsApr.21,2025

-

Scaffolding Solutions for Every ProjectNewsApr.21,2025

-

Innovative Construction Solutions for a Stronger FutureNewsApr.21,2025

-

Essential Steel Keel Solutions for Maximum Protection and PerformanceNewsApr.21,2025

-

Building a solid foundation: The importance of high-quality concrete reinforcement accessoriesNewsApr.21,2025

-

Effective Reinforcement for Stronger StructuresNewsApr.21,2025

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025