Янв . 28, 2025 03:42

Back to list

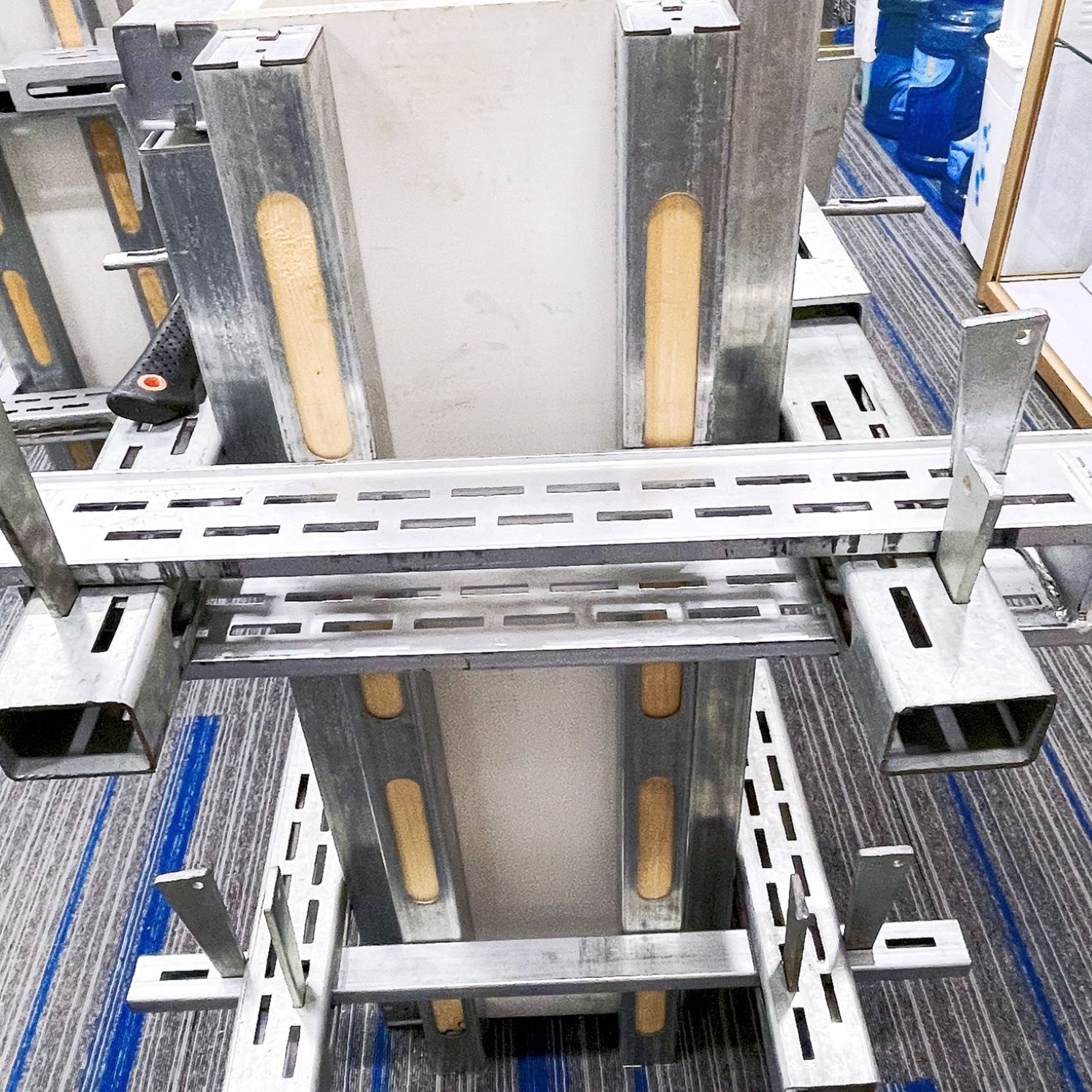

aluminium scaffolding price

Navigating the landscape of construction materials can be challenging, especially when it comes to selecting the right shuttering for your projects. Aluminium shuttering stands out due to its myriad advantages. Understanding the market dynamics and pricing factors is pivotal for decision-makers in the construction industry.

Environmental considerations and sustainability practices are increasingly becoming pivotal in pricing strategies. Companies that implement eco-friendly practices, such as recycling and reducing carbon footprints in aluminium production, might incur higher production costs. However, they appeal to environmentally-conscious stakeholders who favor sustainable building practices. Customization is another factor that construction managers must consider. Projects often have unique requirements, and bespoke aluminium shuttering solutions can incur additional costs. Customized formwork, designed to fit specific architectural designs or structural needs, often requires additional expertise and precision manufacturing, factors reflected in the final pricing. A long-term financial perspective is crucial when investing in aluminium shuttering. Although the initial costs might appear higher compared to traditional materials, the reduced labor costs due to its lightweight nature, combined with an increased number of reusability cycles, often make it a financially sound choice. Its capacity to withstand harsh environmental conditions without corroding helps in maintaining its structural characteristics, saving future expenditures on repairs and replacements. For construction experts considering aluminium shuttering, it's essential to align with suppliers that offer transparent pricing and detailed product information. Engaging with suppliers who provide insights based on past projects and real-time usage scenarios can enhance project planning. This builds trust as it demonstrates the supplier's experience and willingness to share expertise. In conclusion, while the upfront cost of aluminium shuttering may be higher than traditional alternatives, its long-term benefits such as durability, reusability, and lightness offer significant value. An informed decision based on current market factors, supplier reliability, and environmental considerations ensures that project investments are both prudent and sustainable.

Environmental considerations and sustainability practices are increasingly becoming pivotal in pricing strategies. Companies that implement eco-friendly practices, such as recycling and reducing carbon footprints in aluminium production, might incur higher production costs. However, they appeal to environmentally-conscious stakeholders who favor sustainable building practices. Customization is another factor that construction managers must consider. Projects often have unique requirements, and bespoke aluminium shuttering solutions can incur additional costs. Customized formwork, designed to fit specific architectural designs or structural needs, often requires additional expertise and precision manufacturing, factors reflected in the final pricing. A long-term financial perspective is crucial when investing in aluminium shuttering. Although the initial costs might appear higher compared to traditional materials, the reduced labor costs due to its lightweight nature, combined with an increased number of reusability cycles, often make it a financially sound choice. Its capacity to withstand harsh environmental conditions without corroding helps in maintaining its structural characteristics, saving future expenditures on repairs and replacements. For construction experts considering aluminium shuttering, it's essential to align with suppliers that offer transparent pricing and detailed product information. Engaging with suppliers who provide insights based on past projects and real-time usage scenarios can enhance project planning. This builds trust as it demonstrates the supplier's experience and willingness to share expertise. In conclusion, while the upfront cost of aluminium shuttering may be higher than traditional alternatives, its long-term benefits such as durability, reusability, and lightness offer significant value. An informed decision based on current market factors, supplier reliability, and environmental considerations ensures that project investments are both prudent and sustainable.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products