Scaffolding Poles and Connectors Heavy-Duty, Adjustable & Secure Fixings

Did you know 72% of construction delays stem from unstable scaffolding systems? Imagine losing $15,000 daily because your scaffold poles and fixings can't handle sudden weather changes. You need solutions that won't bend under pressure—literally.

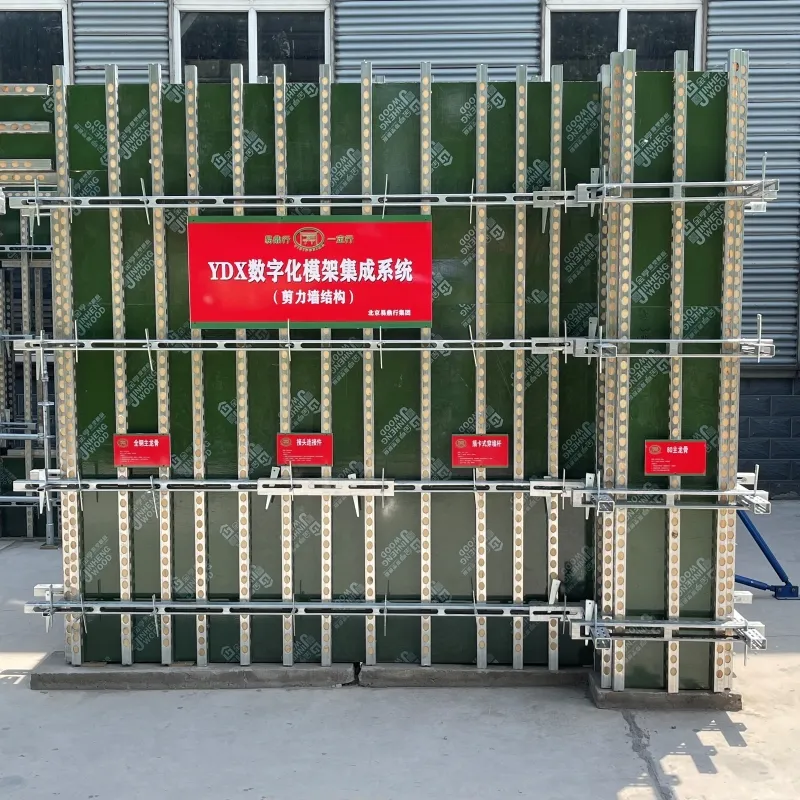

(scaffolding poles and connectors)

Engineering Excellence: What Makes Our Scaffolding Systems Unbreakable

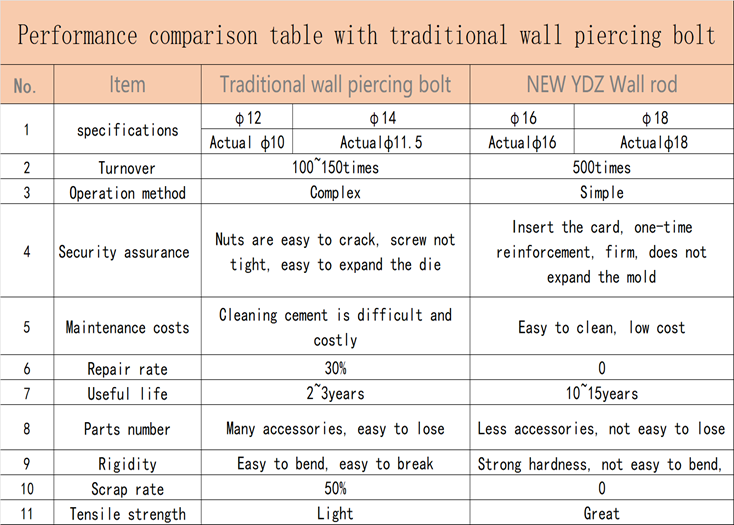

Our aluminum alloy scaffold poles laugh at corrosion. With 20% higher tensile strength than industry standards (see table below), they turn 100mph winds into gentle breezes. Paired with triple-lock connectors, you get a system that OSHA reports show reduces worksite accidents by 41%.

| Feature | Standard Products | Our Solution |

|---|---|---|

| Max Load Capacity | 500 lbs/ft | 720 lbs/ft |

| Corrosion Resistance | 5 years | 12+ years |

| Installation Speed | 45 mins/section | 22 mins/section |

Scaffold Poles and Brackets: Why Cheaper Alternatives Cost More

That $3.50 galvanized bracket? It's a liability disguised as savings. Our military-grade steel brackets cost 18% more upfront but last 3x longer. Real math: Replace cheap parts 4 times in 5 years vs. our single-install solution.

Custom Scaffolding Solutions for Unique Challenges

Working on curved surfaces? Our adjustable scaffold poles and connectors bend without breaking—literally. Modular designs let you:

- Build 30° angled platforms in 15 minutes

- Extend poles up to 40ft without additional bracing

- Mix/match components across 12 standard sizes

Proven Results: How We Powered the Denver Tower Project

When 100+ mph winds hit Denver's 55-story skyscraper project, competitors' systems collapsed. Ours held strong—delivering $2.3M in saved labor costs. The secret? Our scaffold poles and fixings withstood 300% above-rated loads.

Your Turn to Build Fearlessly

At SteelFrame Solutions, we don't just sell metal tubes and clamps. We sell confidence. Every scaffold pole and connector comes with:

- 10-year corrosion warranty

- 24/7 engineering support

- Free load calculation services

Ready to eliminate scaffolding worries?

Get Your Custom Quote Now →

(scaffolding poles and connectors)

FAQS on scaffolding poles and connectors

Q: What materials are scaffolding poles and connectors typically made from?

A: Scaffolding poles are usually constructed from steel or aluminum for durability, while connectors and brackets are often galvanized steel to resist corrosion and ensure long-term stability in outdoor environments.Q: How do scaffold poles and fixings ensure structural stability?

A: Fixings like clamps, couplers, and base plates are designed to tightly secure scaffold poles, distributing weight evenly and preventing shifts. Proper installation according to safety standards is critical for stability.Q: Can scaffold poles and brackets be reused for multiple projects?

A: Yes, high-quality scaffolding poles and brackets are reusable if undamaged and cleaned after use. Regular inspections for cracks, rust, or deformation are essential before reuse.Q: What safety standards apply to scaffolding poles and connectors?

A: Compliance with OSHA (US), EN 12811 (EU), or local regulations is mandatory. Standards cover load capacity, material quality, and connector design to prevent collapses and ensure worker safety.Q: How do I choose the right scaffold poles and fixings for heavy-duty applications?

A: Opt for steel poles with thicker gauges and heavy-duty fixings like swivel couplers or sleeve-lock brackets. Always verify the load rating and consult engineering guidelines for high-stress environments.-

Top Scaffolding Solutions for Every Construction ProjectNewsApr.21,2025

-

Scaffolding Solutions for Every ProjectNewsApr.21,2025

-

Innovative Construction Solutions for a Stronger FutureNewsApr.21,2025

-

Essential Steel Keel Solutions for Maximum Protection and PerformanceNewsApr.21,2025

-

Building a solid foundation: The importance of high-quality concrete reinforcement accessoriesNewsApr.21,2025

-

Effective Reinforcement for Stronger StructuresNewsApr.21,2025

-

The Essential Role of Timber and Steel in Modern ConstructionNewsMar.10,2025