Fev . 12, 2025 15:45

Back to list

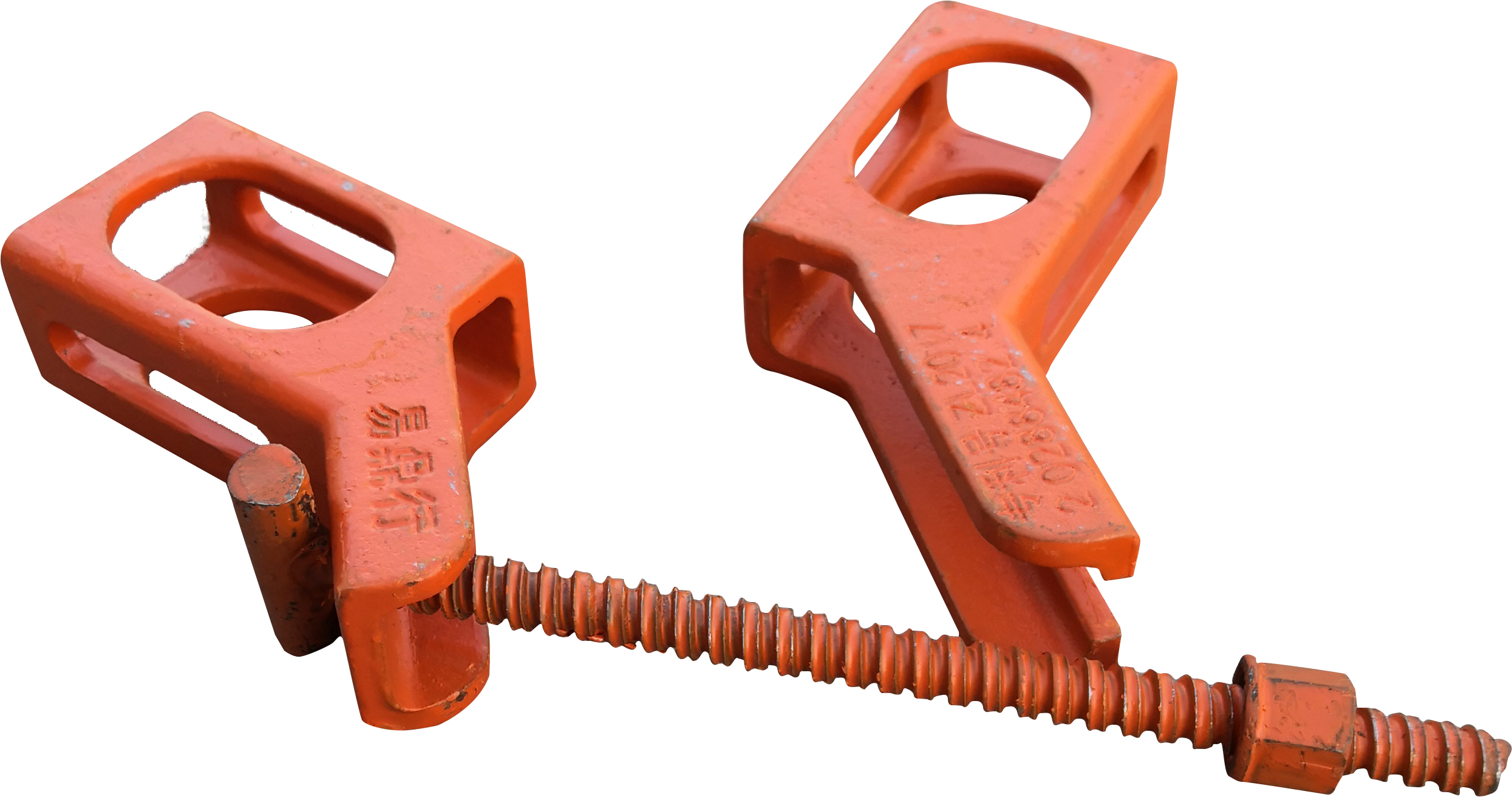

Scaffolding

Diagonal brace scaffolding is a fundamental component in construction, providing robust support and ensuring worker safety at elevated heights. As an expert in the field, understanding the advantages and appropriate application of diagonal brace scaffolding is essential for construction professionals aiming to optimize their project's structural integrity and worker protection. Here, we delve into the intricacies and benefits of diagonal brace scaffolding, enhancing your project’s stability while complying with industry regulations.

Authoritativeness in the matter is reinforced through adherence to established standards such as those prescribed by OSHA (Occupational Safety and Health Administration) or similar governing entities worldwide. Structural engineers regularly consult extensive empirical data and case studies to optimize scaffolding design, ensuring that every aspect from load distribution to wind resistance meets these rigorous standards. Advanced knowledge in materials science also plays a role, as the choice of high-strength materials like steel or aluminum can significantly enhance the scaffolding’s performance. Trustworthiness is underscored by real-world performance and rigorous testing of diagonal brace scaffolding systems before deployment on-site. Ensuring that these systems have undergone third-party testing and certification further assures stakeholders of their reliability. Many manufacturers provide documentation and training to end users, optimizing the installation process and ensuring that all safety protocols are adhered to. For those in the market for effective scaffolding solutions, the choice of diagonal brace scaffolding should be informed by a detailed understanding of the project’s needs and the supplier's track record. Assessing a manufacturer’s expertise and support, availability of components, and the applicability of their systems to your specific use case will enhance the decision-making process. Consulting with structural engineers and scaffolding specialists is advisable to leverage insights that could improve scaffold integration into complex architectural plans. In conclusion, diagonal brace scaffolding is not merely an option but a strategic choice in modern construction, offering unmatched stability, adaptability, and safety. Its deployment is a mark of professionalism and a commitment to maintaining high safety standards in construction. As you embark on your next project, consider diagonal brace scaffolding as a pivotal partner in achieving both structural excellence and worker protection.

Authoritativeness in the matter is reinforced through adherence to established standards such as those prescribed by OSHA (Occupational Safety and Health Administration) or similar governing entities worldwide. Structural engineers regularly consult extensive empirical data and case studies to optimize scaffolding design, ensuring that every aspect from load distribution to wind resistance meets these rigorous standards. Advanced knowledge in materials science also plays a role, as the choice of high-strength materials like steel or aluminum can significantly enhance the scaffolding’s performance. Trustworthiness is underscored by real-world performance and rigorous testing of diagonal brace scaffolding systems before deployment on-site. Ensuring that these systems have undergone third-party testing and certification further assures stakeholders of their reliability. Many manufacturers provide documentation and training to end users, optimizing the installation process and ensuring that all safety protocols are adhered to. For those in the market for effective scaffolding solutions, the choice of diagonal brace scaffolding should be informed by a detailed understanding of the project’s needs and the supplier's track record. Assessing a manufacturer’s expertise and support, availability of components, and the applicability of their systems to your specific use case will enhance the decision-making process. Consulting with structural engineers and scaffolding specialists is advisable to leverage insights that could improve scaffold integration into complex architectural plans. In conclusion, diagonal brace scaffolding is not merely an option but a strategic choice in modern construction, offering unmatched stability, adaptability, and safety. Its deployment is a mark of professionalism and a commitment to maintaining high safety standards in construction. As you embark on your next project, consider diagonal brace scaffolding as a pivotal partner in achieving both structural excellence and worker protection.

Share

Next:

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products