Jan . 14, 2025 10:38

Back to list

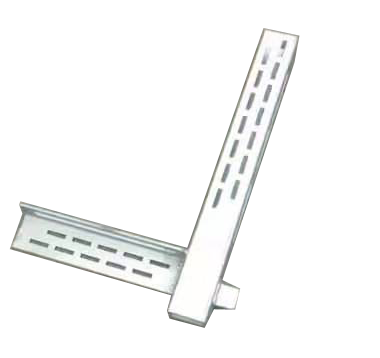

concrete floor formwork

Concrete floor formwork plays a pivotal role in the construction industry, acting as the backbone for any successful flooring project. Selecting the right formwork solution is critical for ensuring structural integrity, cost-effectiveness, and project efficiency. Drawing upon decades of industry experience, we explore the nuances of choosing, implementing, and maintaining concrete floor formwork.

For projects seeking authoritative consultation, collaboration with manufacturers and suppliers with a robust track record is advisable. Reputable firms not only supply high-quality formwork systems but also provide valuable insights into innovative practices and habitual pitfalls. Their authoritative guidance can be instrumental in navigating complex regulatory requirements or addressing unique project challenges. Trustworthiness is typically gauged by a company's reputation and the reliability of its products. Formwork suppliers committed to sustainability and safety audits help reduce environmental impact and uphold high safety standards on job sites. Moreover, warranties and certifications offered by these suppliers add an extra layer of trust, assuring clients of their commitment to quality and safety. To conclude, concrete floor formwork is an investment in the longevity and success of construction projects. Leveraging expert insights, staying informed on materials and techniques, and opting for reputable suppliers are strategies that ensure the optimal performance of floor formwork. By prioritizing quality and expertise, stakeholders can safeguard their projects against unforeseen challenges and pave the way for seamless execution. Aspiring to the highest industry standards, stakeholders not only enhance their credibility but also contribute to the advancement of construction practices.

For projects seeking authoritative consultation, collaboration with manufacturers and suppliers with a robust track record is advisable. Reputable firms not only supply high-quality formwork systems but also provide valuable insights into innovative practices and habitual pitfalls. Their authoritative guidance can be instrumental in navigating complex regulatory requirements or addressing unique project challenges. Trustworthiness is typically gauged by a company's reputation and the reliability of its products. Formwork suppliers committed to sustainability and safety audits help reduce environmental impact and uphold high safety standards on job sites. Moreover, warranties and certifications offered by these suppliers add an extra layer of trust, assuring clients of their commitment to quality and safety. To conclude, concrete floor formwork is an investment in the longevity and success of construction projects. Leveraging expert insights, staying informed on materials and techniques, and opting for reputable suppliers are strategies that ensure the optimal performance of floor formwork. By prioritizing quality and expertise, stakeholders can safeguard their projects against unforeseen challenges and pave the way for seamless execution. Aspiring to the highest industry standards, stakeholders not only enhance their credibility but also contribute to the advancement of construction practices.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products