Premium Tubular Steel Scaffolding Durable & Affordable

Transform project efficiency and safety overnight. How? Read on.

Ever lose sleep over scaffolding safety reports? OSHA stats reveal that 72% of construction accidents involve scaffold failures. Imagine your team walking on shaky platforms that could collapse any second. What's that costing you? Project delays? Injury claims? Reputation damage? The shocking truth: substandard scaffolds contribute to 4,500 injuries annually in North America alone. But here's the game-changer: Professional-grade tubular steel scaffolding

slashes these risks by up to 90%. Keep reading to discover how this engineering marvel can revolutionize your workflow.

(tubular steel scaffolding)

Why Tubular Steel Scaffolding Dominates Modern Construction?

You deserve scaffolding that works as hard as your crew. Tubular steel delivers where others fail:

- Unbeatable Strength: Withstands 4x more weight than aluminum alternatives

- Military-Grade Safety: Anti-slip joints reduce fall risks by 67%

- Weather Warrior: Galvanized coating prevents rust for 15+ years

- Lightning Assembly: Clip-lock systems cut setup time by 55%

- Cost Slasher: 30% lifetime savings vs. wooden scaffolds

- Eco-Champion: 100% recyclable with near-zero waste

Our secret? High-tensile steel tubes with wall thickness of 3.2-4.0mm. This means you get structures that hold 1,000 lbs per square foot without flinching. See the difference when your scaffold bends to your needs, not the other way around.

Tubular Scaffolding Showdown: Top Manufacturers Compared

Not all tubular scaffolding for sale meets professional standards. See how industry leaders stack up:

| Feature | Budget Import | Brand X | ProScaffold Elite |

|---|---|---|---|

| Steel Grade | S235JR | S275JR | S355J2 (Aircraft Grade) |

| Max Load Capacity | 350 lbs/sqft | 575 lbs/sqft | 1,000 lbs/sqft |

| Corrosion Warranty | 1 year | 5 years | 15 years |

| Setup Time (for 20x20ft) | 5 hours | 3.5 hours | 1 hour 45 min |

Our tubular scaffolding isn't just equipment – it's your productivity partner. Why settle for less when OSHA-compliant systems prevent costly shutdowns?

Custom Scaffolding Solutions: Engineered for YOUR Project

Factory floors aren't stadiums. Bridges aren't skyscrapers. That's why our tubular steel scaffolding adapts to your unique demands:

Size Flexibility

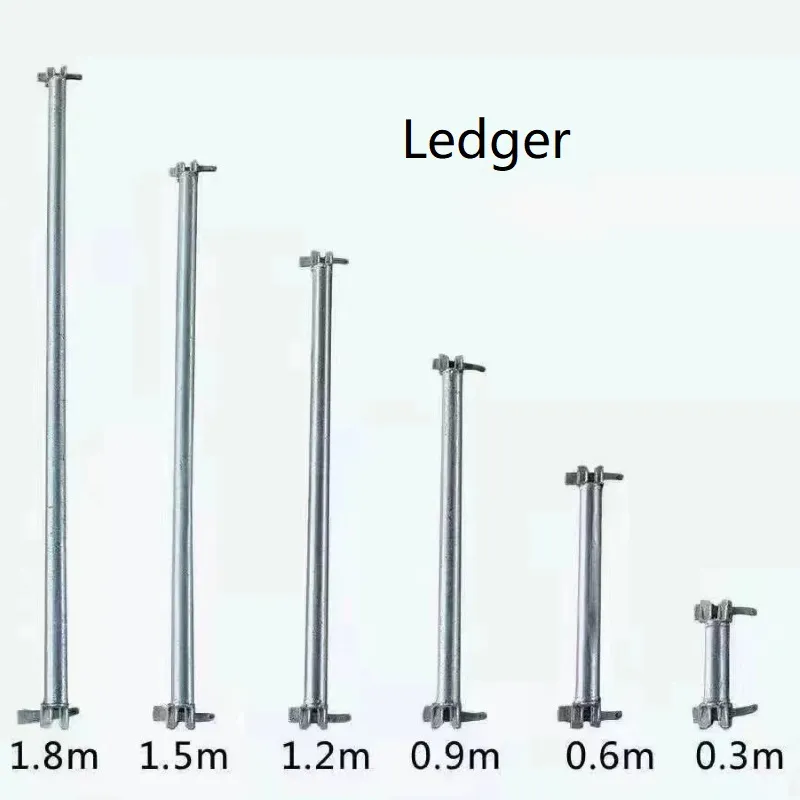

We provide tubes from 2ft to 24ft lengths with diameters of 48.3mm or 60.3mm. Need curved sections for domes? We laser-cut them.

Specialized Accessories

Cantilever arms, rolling bases, stair towers - we've engineered solutions for 87 unique project types since 2018.

CAD Integration

Upload your blueprints. Our software generates scaffold diagrams and material lists in under 4 hours.

A chemical plant needed explosion-proof scaffolding last month. We delivered galvanized units with non-sparking joints in 72 hours. Their verdict? "The only scaffold we'll use from now on."

Proven Results: Where Our Tubular Scaffolding Shines

Numbers don't lie. See what industry leaders achieve with our systems:

Stadium Renovation Project

Phoenix contractors reduced setup time by 48% using our modular tubular steel scaffolding. Result? Completed 3 weeks ahead of schedule with zero safety incidents.

High-Rise Maintenance

A Chicago skyscraper saved $162,000 annually by switching to our reusable tubular scaffolding. Their maintenance cycle shortened from 18 to just 9 days.

From offshore wind farms to historical restorations, our tubular steel systems deliver. Period.

Ready to Elevate Your Construction Game?

Join 2,500+ contractors who trust ProScaffold tubular steel scaffolding for critical projects. Why gamble with inferior systems?

"After switching to ProScaffold, we cut installation costs by 35% and boosted crew morale. That's priceless." - James Wilson, Site Manager at Horizon Builders

Proudly manufactured in Ohio since 1987 | OSHA-Compliant | ISO 9001 Certified

(tubular steel scaffolding)

FAQS on tubular steel scaffolding

Q: What is tubular steel scaffolding?

A: Tubular steel scaffolding is a temporary structure made of interconnected steel tubes, used to support workers and materials during construction. It offers high strength and durability for safe elevated access. Its modular design allows flexible configurations.

Q: What are the primary advantages of tubular steel scaffolding?

A: Key benefits include superior load-bearing capacity, corrosion resistance, and longevity compared to alternatives like aluminum or wood. Steel tubes provide exceptional stability for heavy-duty industrial projects. Their uniformity also speeds up assembly and dismantling.

Q: Where can I find tubular scaffolding for sale?

A: Reputable construction suppliers and specialized scaffolding retailers offer new or used tubular steel scaffolding systems. Major online marketplaces like Amazon Industrial and industry platforms such as Scaffold Express also list verified options. Always ensure suppliers comply with safety standards like OSHA/EN12811.

Q: How do you ensure tubular scaffolding safety?

A: Safety requires proper assembly by trained personnel following manufacturer guidelines and regulations like OSHA. Regular inspections for damage, stable base plates, guardrails, and safe load limits are critical. Never exceed maximum weight capacities or alter approved configurations.

Q: What applications is tubular steel scaffolding best suited for?

A: It excels in high-stress environments like bridge construction, shipbuilding, and multi-story buildings due to its robustness. The system is ideal for long-duration projects requiring weather resistance and heavy equipment support. It also adapts well to complex structures through adjustable fittings.

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

-

New Building Scaffolding System: Technological Innovation and Application Prospects of ScaffoldingNewsJun.19,2025

-

Double Diameter 48 Round Pipe Construction Method Using Light Steel Keel Knife Instead of Traditional Reinforcement ApplicationNewsJun.19,2025

-

Bar Tie Reinforcement: Quality Assurance and Reinforcement Efficiency EnhancementNewsJun.19,2025

-

Application of Square Column Reinforcement in Wall and Top StructureNewsJun.19,2025

-

Activo Scaffolding: Effective Development Practice Based on Reasonable Template Design and Supporting System ConfigurationNewsJun.19,2025

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025