Feb . 15, 2025 05:02

Back to list

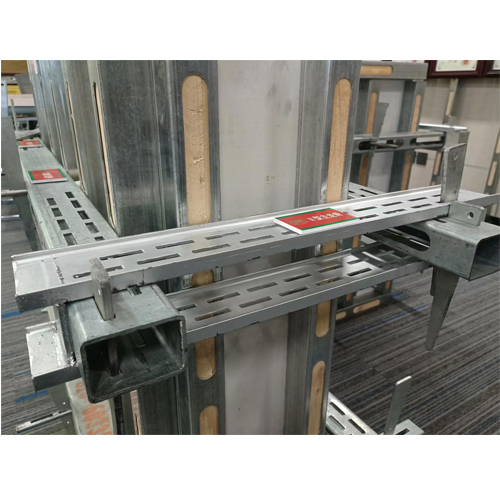

aluminium scaffolding for sale

Temporary roof scaffolding has become an indispensable component in construction and renovation projects, offering both safety and accessibility for workers. Understanding its costs is crucial for project managers and builders alike. This insight into temporary roof scaffolding costs, grounded in industry experience and expertise, explores key factors influencing pricing and valuable cost-saving strategies.

3. Reuse and Recycle Consider utilizing reusable scaffolding components. This can significantly reduce costs over multiple projects, especially when investing in quality materials that withstand wear and tear. 4. Regular Maintenance Well-maintained scaffolding extends the life of materials and reduces the likelihood of unexpected repairs or replacements. Regular inspections and maintenance by certified professionals ensure safety and cost-effectiveness. 5. Training and Safety Investing in training for your scaffold team ensures efficient use and compliance with safety regulations. Safety reduces the risk of accidents and associated costs, emphasizing the importance of a well-trained workforce. Emphasizing Safety and Compliance Temporary roof scaffolding is paramount for construction safety and efficiency. Emphasizing safety doesn’t just avert accidents but also ensures compliance with local building regulations, which can prevent costly fines or project delays. The Occupational Safety and Health Administration (OSHA) and similar organizations set forth stringent standards for scaffolding construction and use. Compliance with these standards not only ensures worker safety but also minimizes legal liabilities, safeguarding the project's financial and reputational investments. Balancing Costs with Quality and Expertise While cost management is crucial, ensuring scaffolding quality and employing expert labor is equally important. Low-cost solutions may jeopardize safety and project integrity. Therefore, balancing costs with quality materials and skilled labor is essential for both safety and long-term savings. Professional consultation on scaffolding requirements and site-specific challenges can provide valuable insights. Engaging experts in scaffolding not only optimizes design and functionality but also identifies potential cost-saving measures without compromising safety or performance. Conclusion Understanding the dynamics of temporary roof scaffolding costs involves careful consideration of materials, labor, and project specifics. By implementing strategic planning and engaging experienced professionals, it is possible to manage expenses effectively while upholding safety and compliance standards. This balanced approach not only leverages industry expertise but also establishes a foundation of trustworthiness and authority in managing temporary scaffolding needs, ensuring successful project outcomes.

3. Reuse and Recycle Consider utilizing reusable scaffolding components. This can significantly reduce costs over multiple projects, especially when investing in quality materials that withstand wear and tear. 4. Regular Maintenance Well-maintained scaffolding extends the life of materials and reduces the likelihood of unexpected repairs or replacements. Regular inspections and maintenance by certified professionals ensure safety and cost-effectiveness. 5. Training and Safety Investing in training for your scaffold team ensures efficient use and compliance with safety regulations. Safety reduces the risk of accidents and associated costs, emphasizing the importance of a well-trained workforce. Emphasizing Safety and Compliance Temporary roof scaffolding is paramount for construction safety and efficiency. Emphasizing safety doesn’t just avert accidents but also ensures compliance with local building regulations, which can prevent costly fines or project delays. The Occupational Safety and Health Administration (OSHA) and similar organizations set forth stringent standards for scaffolding construction and use. Compliance with these standards not only ensures worker safety but also minimizes legal liabilities, safeguarding the project's financial and reputational investments. Balancing Costs with Quality and Expertise While cost management is crucial, ensuring scaffolding quality and employing expert labor is equally important. Low-cost solutions may jeopardize safety and project integrity. Therefore, balancing costs with quality materials and skilled labor is essential for both safety and long-term savings. Professional consultation on scaffolding requirements and site-specific challenges can provide valuable insights. Engaging experts in scaffolding not only optimizes design and functionality but also identifies potential cost-saving measures without compromising safety or performance. Conclusion Understanding the dynamics of temporary roof scaffolding costs involves careful consideration of materials, labor, and project specifics. By implementing strategic planning and engaging experienced professionals, it is possible to manage expenses effectively while upholding safety and compliance standards. This balanced approach not only leverages industry expertise but also establishes a foundation of trustworthiness and authority in managing temporary scaffolding needs, ensuring successful project outcomes.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products