Revolutionizing Formwork Systems: Keel Steel

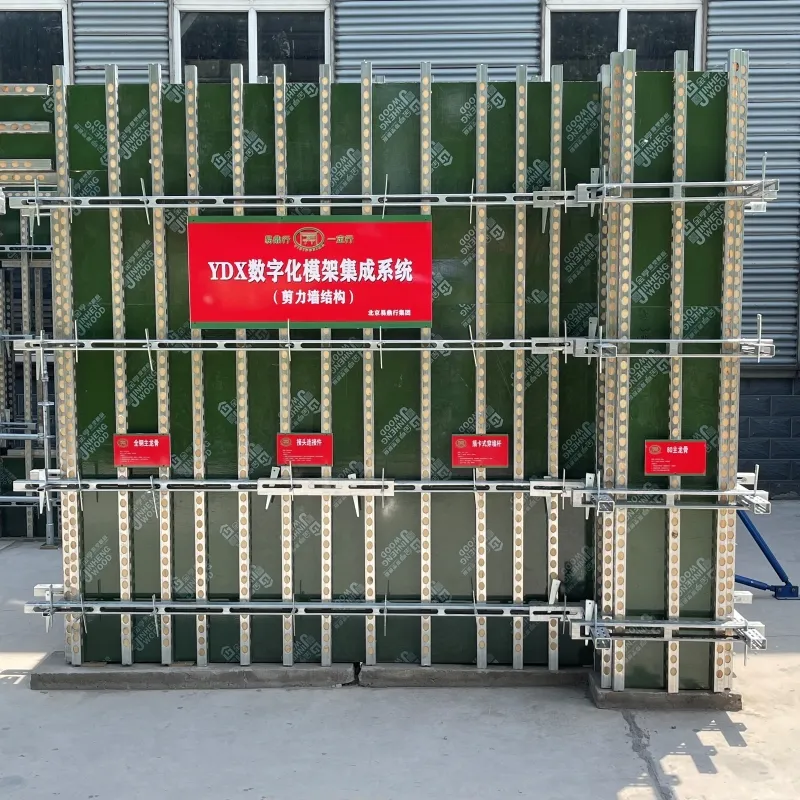

The construction process of steel keel is an advanced formwork system composed of wood/plastic formwork + keel steel with matching components. This system offers:

- Superior rigidity and stability with light weight components

- Standardized, modular design for easy assembly

- High recyclability with up to 1000 turnover cycles

- 50*70mm specification with 3.0mm wall thickness

- Full hot-galvanized protection for enhanced durability

Steel Keel Technology Trends

The construction industry has increasingly adopted steel keel systems as sustainable alternatives to traditional wood formwork. According to recent data from the Journal of Construction Engineering, structural systems using steel formworks provide up to 40% faster assembly times compared to conventional methods (Source: ASCE Journals).

Global Steel Keel Market Growth (2020-2030)

Technical Specifications of Steel Keel Systems

Comparative Steel Keel Specifications

| Parameter | Light Steel Keel | Traditional Steel | YDX Keel Steel |

|---|---|---|---|

| Dimensions | 50*40mm | 60*80mm | 50*70mm |

| Wall Thickness | 1.2-1.5mm | 2.0-2.5mm | 3.0mm |

| Weight Per Meter | 2.8kg | 5.2kg | 3.94kg |

| Yield Strength | 235 MPa | 345 MPa | 355 MPa |

| Max Turnover | 300 cycles | 500 cycles | 1000 cycles |

| Corrosion Protection | Electro-galvanized | Paint coating | Hot-dip galvanized |

Weight Comparison (kg/m)

Load Capacity (kN/m)

Turnover Cycles

Corrosion Resistance Rating

Steel Keel Application Scenarios

The steel keel finds extensive applications across construction environments. Here are the primary implementations according to construction standards:

High-Rise Buildings

Steel keel formwork systems provide the stability needed for vertical concrete structures in tall buildings. The modular design accelerates construction time while ensuring precision alignment.

Tunnel Construction

In curved tunnel applications, specialized light steel keel components maintain structural integrity under lateral pressure. Their corrosion resistance makes them ideal for underground environments.

Infrastructure Projects

Bridges and overpasses utilize stainless steel keel bands in critical joints and expansions. These components withstand environmental stresses that standard steel cannot endure.

Real-World Application: Shanghai Tower Project

The Shanghai Tower project utilized YDX's keel steel system for its core wall construction. According to the International Journal of High-Rise Buildings, the use of specialized steel formwork reduced construction time by 28% compared to traditional methods (CTBUH Journal).

Steel Keel Professional FAQ

What distinguishes light steel keel from traditional options?

Light steel keel features thinner wall sections (1.0-2.0mm) utilizing high-strength steels, reducing weight while maintaining structural capacity. Traditional keels have thicker walls with conventional steel compositions.

What does "steel keel in english" mean structurally?

The term "steel keel" refers to the primary load-bearing framework of a formwork system. Functionally analogous to a ship's keel, it provides foundational support and alignment for concrete forming operations.

What are standard steel keel specifications?

Common specifications range from 50×30mm to 100×50mm rectangular sections, with wall thicknesses from 1.2mm to 3.0mm. ASTM standards specify material compositions of either Q235 or Q345 steel with yield strengths of 235-345 MPa.

When is stainless steel keel band necessary?

Stainless bands provide critical corrosion protection in coastal environments, chemical facilities, or structures requiring longevity beyond standard galvanized protection. They withstand chloride exposure that degrades regular steel.

What installation tolerances apply to steel keel systems?

ANSI A10.9-1997 specifies maximum vertical deviations of ±5mm per 3m height and ±6mm alignment variance between adjacent keel sections. Proper installation prevents concrete dimensional irregularities.

How do thermal properties affect steel keel selection?

All materials expand under temperature variation. Steel has a thermal expansion coefficient of 12×10⁻⁶/°C. Design must account for potential daily variations of 15-30°C, especially in exposed applications.

What maintenance ensures maximum steel keel lifecycle?

Post-use cleaning to remove concrete residue, inspection for deformation, protective coating touch-ups, and proper stacking/storage away from moisture. Consistent maintenance achieves 1000+ turnover cycles in hot-dip galvanized systems.

Industry Perspective on Steel Keel Evolution

The future of steel keel technology focuses on material science breakthroughs. As noted in Construction and Building Materials journal:

"Advanced high-strength steels (AHSS) and nano-coating technologies will push keel system capabilities to new thresholds. The next generation may offer 25% greater strength-to-weight ratios while extending service life by a factor of 1.5× through molecular-level corrosion inhibition." Construction and Building Materials Vol. 345 (2022)

The steel keel remains a fundamental component in modern construction methodology. Its continuous refinement reflects the industry's drive toward sustainable, efficient building practices.

Ready to Upgrade Your Formwork System?

Contact our engineering team to discuss steel keel solutions:

HeBei Yidingxing Technology Co.,LTD.

Phone: +8618311022101 | Email: sophie@bj-ydx.cn

Download Product Specifications