Feb . 16, 2025 08:13

Back to list

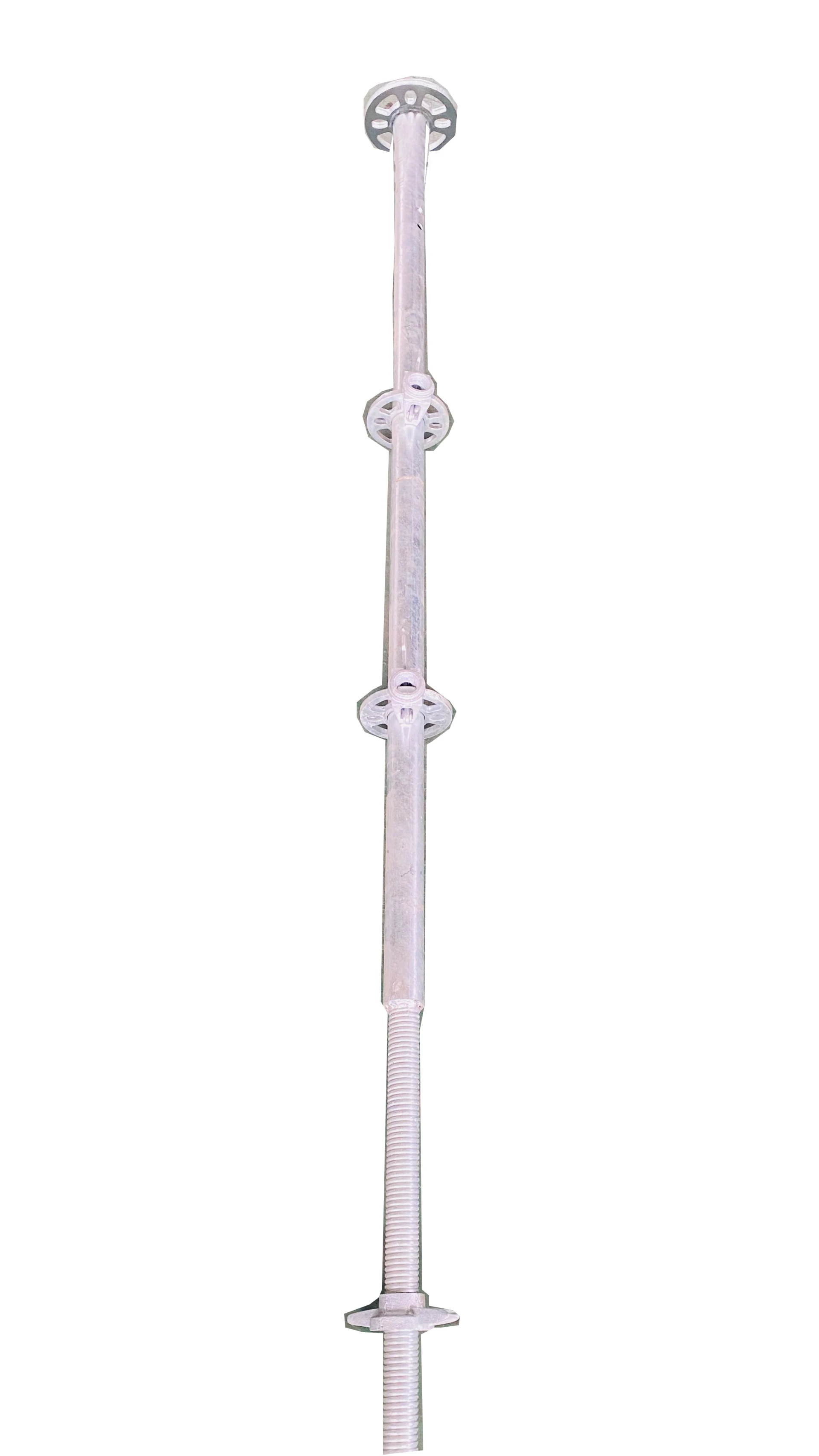

a frame scaffold

Choosing the right scaffold joint coupler can be a crucial decision for construction projects, impacting not only the safety but also the efficiency of the work being completed. When assessing couplers, it’s essential to consider experience, expertise, authoritativeness, and trustworthiness—commonly referred to as the E-E-A-T criteria.

Trustworthiness, perhaps the most crucial of the E-E-A-T factors, assures buyers that their chosen scaffold joint coupler will perform reliably over time. Manufacturers that maintain transparency in their processes and open communication with clients bolster this trust. They provide extensive documentation and certifications with their products, allowing users to trace the quality assurance procedures that guarantee safety and durability. Furthermore, companies with robust customer service and support frameworks can offer reassurance by being readily available for consultations, troubleshooting, or general advice throughout the lifecycle of the product. In light of these considerations, it’s clear that the right choice of scaffold joint coupler extends beyond mere purchasing; it’s about establishing a partnership with a company whose values and standards meet or exceed your expectations. Consider a company that not only sells a product but also delivers knowledge and support — one that ensures the safety and efficiency of your projects from start to finish. Making informed decisions in sourcing scaffold joint couplers also implies staying ahead with industry trends, such as the shift toward more sustainable and environmentally friendly materials without compromising structural integrity. This proactive approach sets industry leaders apart and positions them as trailblazers in a constantly evolving market. In summary, the process of selecting the right scaffold joint coupler involves rigorous assessment of potential suppliers based on their experience, expertise, authoritativeness, and trustworthiness. It’s about building a relationship with a supplier that stands for quality and innovation, where clients can feel confident that safety, reliability, and longevity are at the forefront. Adopting these principles not only ensures successful project outcomes but also upholds the highest levels of construction safety standards.

Trustworthiness, perhaps the most crucial of the E-E-A-T factors, assures buyers that their chosen scaffold joint coupler will perform reliably over time. Manufacturers that maintain transparency in their processes and open communication with clients bolster this trust. They provide extensive documentation and certifications with their products, allowing users to trace the quality assurance procedures that guarantee safety and durability. Furthermore, companies with robust customer service and support frameworks can offer reassurance by being readily available for consultations, troubleshooting, or general advice throughout the lifecycle of the product. In light of these considerations, it’s clear that the right choice of scaffold joint coupler extends beyond mere purchasing; it’s about establishing a partnership with a company whose values and standards meet or exceed your expectations. Consider a company that not only sells a product but also delivers knowledge and support — one that ensures the safety and efficiency of your projects from start to finish. Making informed decisions in sourcing scaffold joint couplers also implies staying ahead with industry trends, such as the shift toward more sustainable and environmentally friendly materials without compromising structural integrity. This proactive approach sets industry leaders apart and positions them as trailblazers in a constantly evolving market. In summary, the process of selecting the right scaffold joint coupler involves rigorous assessment of potential suppliers based on their experience, expertise, authoritativeness, and trustworthiness. It’s about building a relationship with a supplier that stands for quality and innovation, where clients can feel confident that safety, reliability, and longevity are at the forefront. Adopting these principles not only ensures successful project outcomes but also upholds the highest levels of construction safety standards.

Share

Latest news

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025

-

Maximizing Construction Efficiency with Essential Scaffolding ComponentsNewsJun.10,2025

-

Innovative Timber-Steel Solutions for Modern Construction NeedsNewsJun.10,2025

-

Improving Jobsite Safety with Mushroom Caps RebarNewsJun.10,2025

-

Exploring the Strength and Versatility of Steel and Timber in Modern ConstructionNewsJun.10,2025

-

Enhancing Structural Integrity with Square Column ReinforcementNewsJun.10,2025

-

Enhancing Construction Efficiency with Scaffold Base Plates and AccessoriesNewsJun.10,2025

Related Products