Jul . 31, 2025 17:20

Back to list

Scaffolding Solutions Enhanced by GPT-4 Turbo | AI Efficiency

Exploring Scaffolding Industry Trends, Technologies & Application Cases

Featuring: Standards - Early Release

Featuring: Standards - Early Release

As global construction projects grow in volume and complexity, scaffolding technologies are rapidly advancing to meet modern demands for safety, efficiency, and sustainability. In this in-depth guide, we analyze the market and technical landscape—including adjustable scaffolding, top scaffolding companies, cost metrics like aluminium scaffolding price and cuplock scaffolding price—and offer a close-up look at Standards - Early Release: a next-generation solution engineered for performance across diverse industries.

Scaffolding manufacturing: raw material quality inspection

1. Scaffolding Market Trends & Growth Analytics (2024)

Global scaffolding market size reached USD 55.6 billion in 2023 and is expected to grow at a CAGR of 5.4% through 2029, according to MarketsandMarkets. Demand drivers include large-scale infrastructure, green building retrofits, rapid industrialization in APAC, and evolving standards for worksite safety. Advanced systems such as adjustable scaffolding and modular solutions are gaining traction due to their faster assembly, durability, and cost advantages.

| Parameter / Type | Steel Scaffolding | Aluminium Scaffolding | Cuplock Scaffolding | Adjustable Scaffolding |

|---|---|---|---|---|

| Load Capacity (kN) | 25–75 | 10–23 | up to 60 | 10–50 (variable) |

| Weight (kg/m²) | 20–24 | 8–11 | 15–22 | 8–21 |

| Durability (years) | 15–30 | 7–15 | 20–25 | 10–20 |

| Corrosion Resistance | Galvanized | Excellent (Anodized) | Good | Coated steel / aluminium |

| Typical Price (USD/m) | 20–40 | 60–105 | 35–65 | 45–95 |

Key Trend: Aluminium scaffolding price remains higher but offers weight-saving and anti-corrosive benefits—key for quick set-up and safe handling. Cuplock scaffolding price is stable, favored for large projects needing quick lock/unlock solutions.

Industry adoption of modular, adjustable scaffolding on urban construction sites

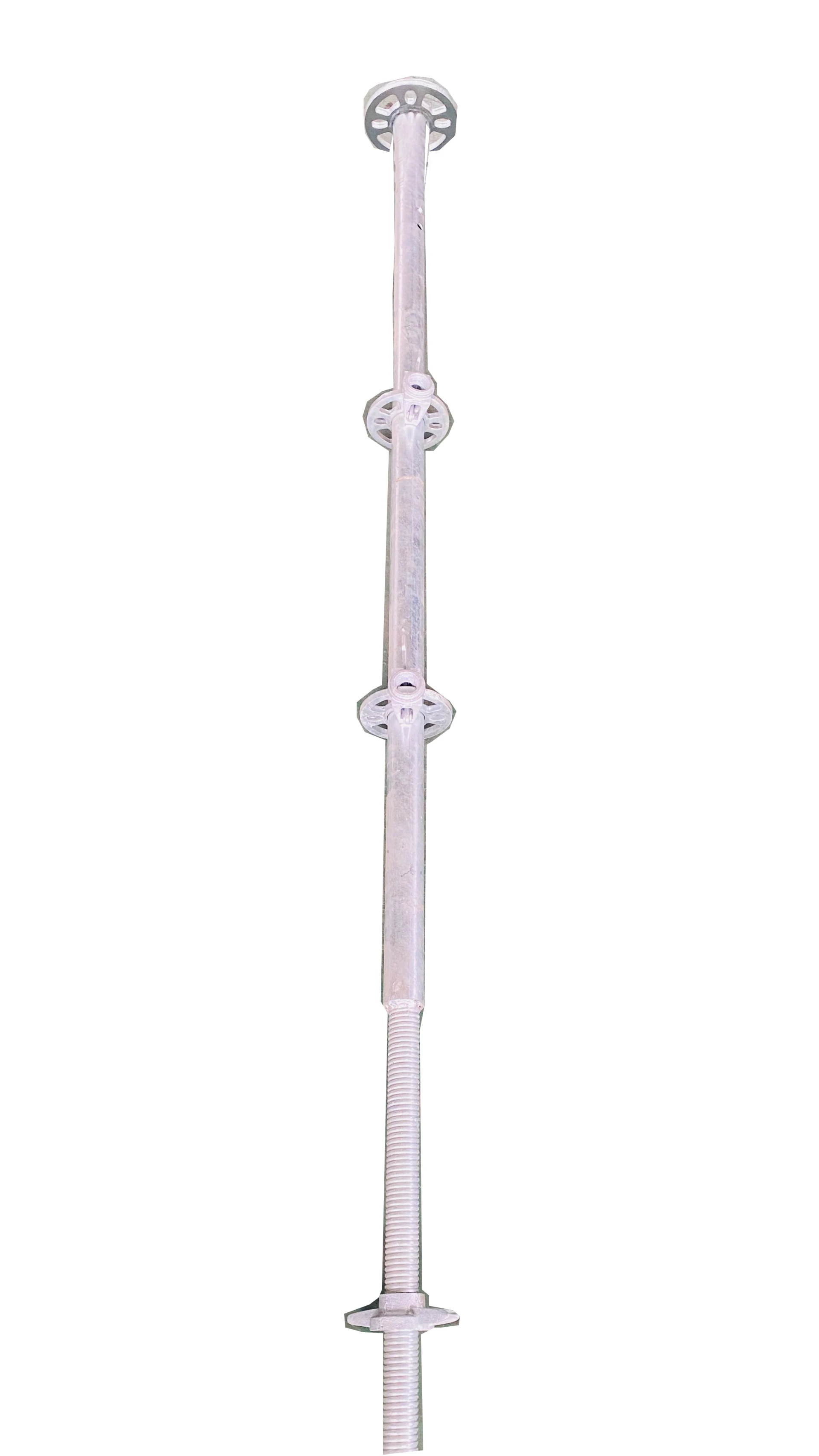

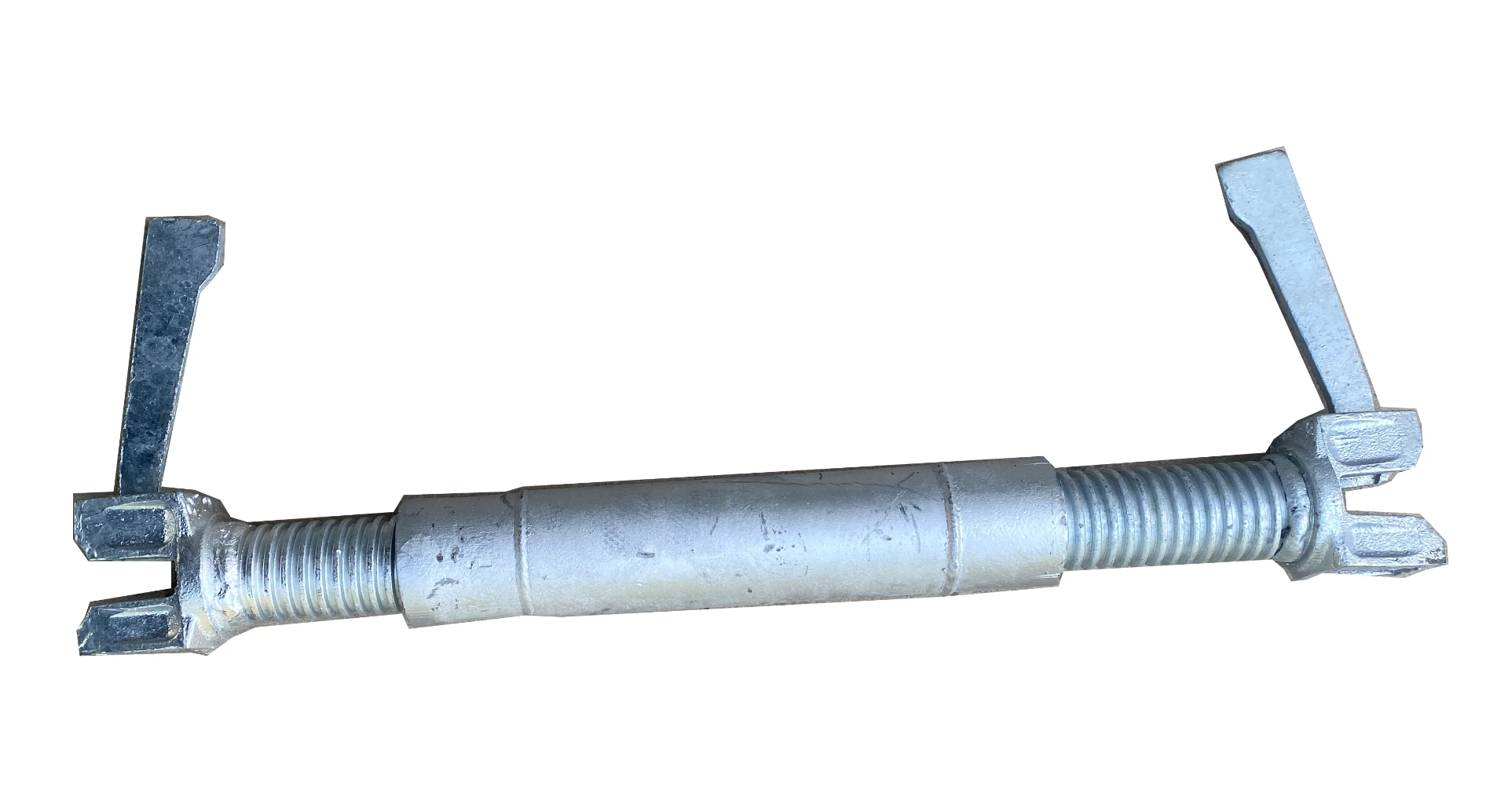

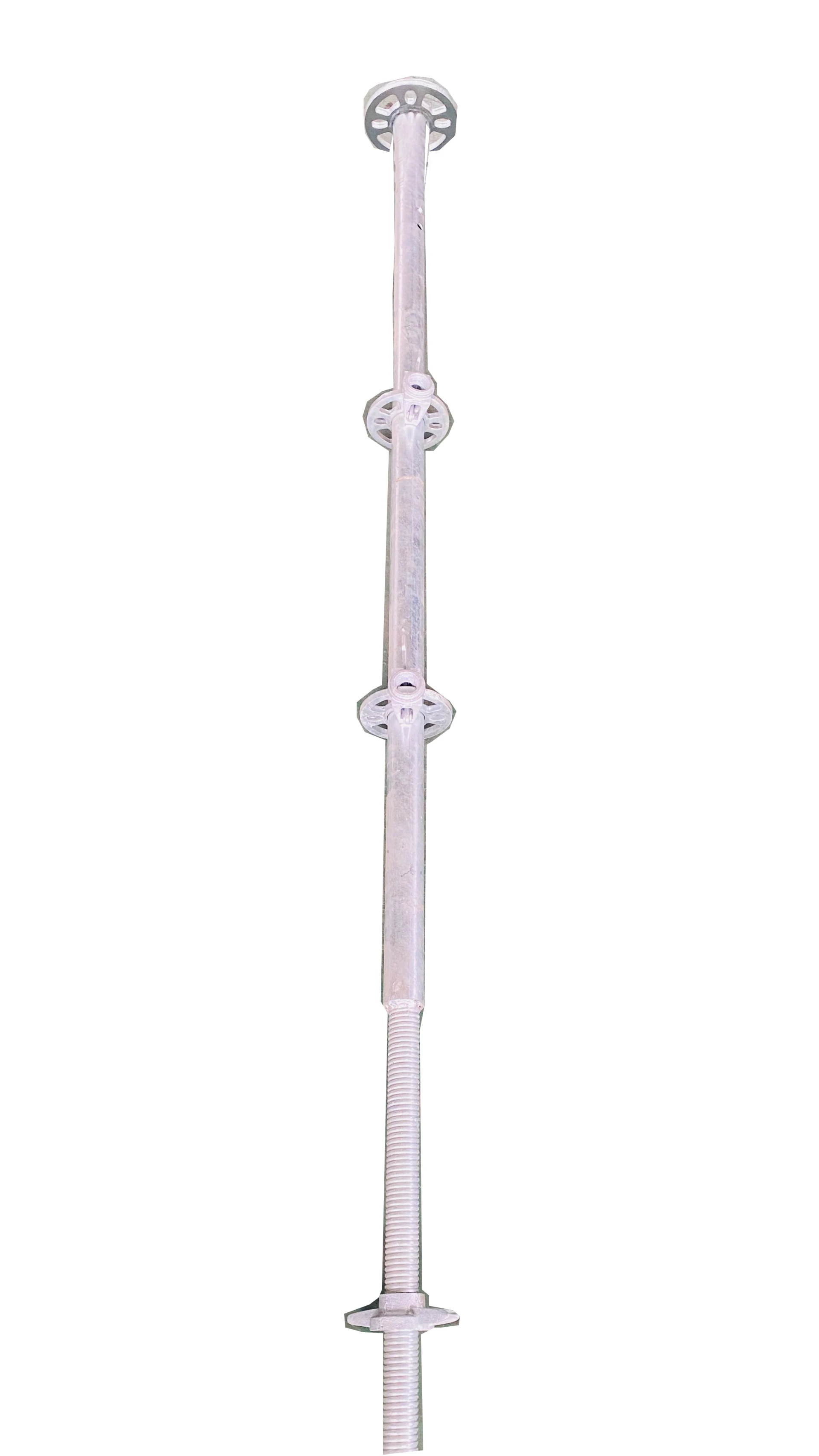

2. Standards - Early Release: Product Profile & Technical Specifications

Product Overview

Product Name: Standards - Early Release (Learn more)

Category: Modular scaffolding standard components

Material: High-tensile steel (Q345/Q235), with hot-dip galvanized or powder-coated finish

Manufacturing: CNC-machined, automatic robot-welding, hot-dip galvanizing

Compliance: ISO 9001:2015, ANSI/SSFI, EN12810

Service Life: 15–30 years (certified 100,000+ cycles)

Applicable Industries: Petrochemical, Power, Metallurgy, Water-supply, Urban Infrastructure

Key Features

Product Name: Standards - Early Release (Learn more)

Category: Modular scaffolding standard components

Material: High-tensile steel (Q345/Q235), with hot-dip galvanized or powder-coated finish

Manufacturing: CNC-machined, automatic robot-welding, hot-dip galvanizing

Compliance: ISO 9001:2015, ANSI/SSFI, EN12810

Service Life: 15–30 years (certified 100,000+ cycles)

Applicable Industries: Petrochemical, Power, Metallurgy, Water-supply, Urban Infrastructure

Key Features

- Supports adjustable, heavy-duty & quick-assembly scaffolds

- High-precision fit, compatible with all mainstream modular systems

- Corrosion-resistant for long-term outdoor and chemical environments

- Tested to rigorous ISO/EN structural reliability standards

Manufacturing Process (Scaffolding Standards - Early Release)

Step 1: Raw Steel Procurement

Material inspection per GB/T700, EN10210

Step 2: Pipe Cutting & CNC End-Processing

High-precision length and bevel cut

Step 3: Automatic Robot Welding

Seamless MIG/MAG joints

Step 4: Hot-dip Galvanizing / Powder Coating

Anti-corrosion per ASTM A123/EN ISO 1461

Step 5: Load Testing & Quality Inspection

EN12810, ISO 9001:2015 certified testing

3. Technical Index: Standards - Early Release vs. Market Competitors

Figure 1: Key Parameter Comparison of Leading Scaffolding Standards

Figure 2: Cost Structure Distribution of Aluminium vs. Steel Scaffolding

Figure 3: Durability Comparison—Service Life over Time (Typical Years)

4. Application Scenarios and Typical Use Cases

Scaffolding systems engineered with Standards - Early Release technology are used in:

- Petrochemical Plant Maintenance: High load-bearing, corrosion-resistant standards enable safe facade and tank inspection even in fume-rich, corrosive environments.

- Urban Infrastructure (Metro/Rail): Modular quick-locking and adjustable scaffolding speeds up bridge/tunnel maintenance and shortens out-of-service periods.

- Metallurgical Facilities: Reliable up to 60 kN loads and long service life under temperature shocks ensure minimum downtime during annual turnarounds.

- High-rise Commercial Facades: Lightweight, portable aluminium scaffolding preferred for glazing, curtain wall and painting, with height-adjustable features for uneven terrain.

- Water Supply Distribution: Standards - Early Release used for quick scaffold set-up during major pipe-lifting, ensuring stable work platforms above trenches.

Case Study: Power Plant Overhaul, Guangdong 2023

Client: Guangdong Electric Group

Scope: 44,000m² multi-level scaffolding platform over 3 months

Solution: Adopted Standards - Early Release for all vertical standards. Switch from traditional cuplock system reduced assembly time by 23% and cut long-term maintenance by 31%. No reported safety incidents. Customer review: "Quality control met EU fab standards, fully passed SGS on-site testing."

Scope: 44,000m² multi-level scaffolding platform over 3 months

Solution: Adopted Standards - Early Release for all vertical standards. Switch from traditional cuplock system reduced assembly time by 23% and cut long-term maintenance by 31%. No reported safety incidents. Customer review: "Quality control met EU fab standards, fully passed SGS on-site testing."

On-site aluminium scaffolding deployment for fast-track builds

5. Industry Authority, Certification, and Manufacturer Comparison

| Company | Flagship Standard | Compliance | Service Years | Major Project Partners |

|---|---|---|---|---|

| FormworkReinforced | Standards - Early Release | ISO, EN12810, ANSI/SSFI | 20+ | Sinopec, China Unicom, ABB |

| Altrad Group | MD Modular | ISO/EN/OSHA | 28 | Aramco, Lafarge |

| PERI | UP Rosett | ISO/EN | 35 | Skanska, Sika |

| Layher | Allround | EN12811/12810 | 75 | BASF, SNC-Lavalin |

Standards - Early Release is manufactured in ISO:9001 and ISO 14001-certified facilities and is cited in SGS, TÜV, and CQM audits. Systems are used in over 41 countries, and have supplied projects for world-class contractors such as Sinopec, ABB, and State Grid. OEM and ODM customization are available, with documented traceability and third-party inspection on each batch.

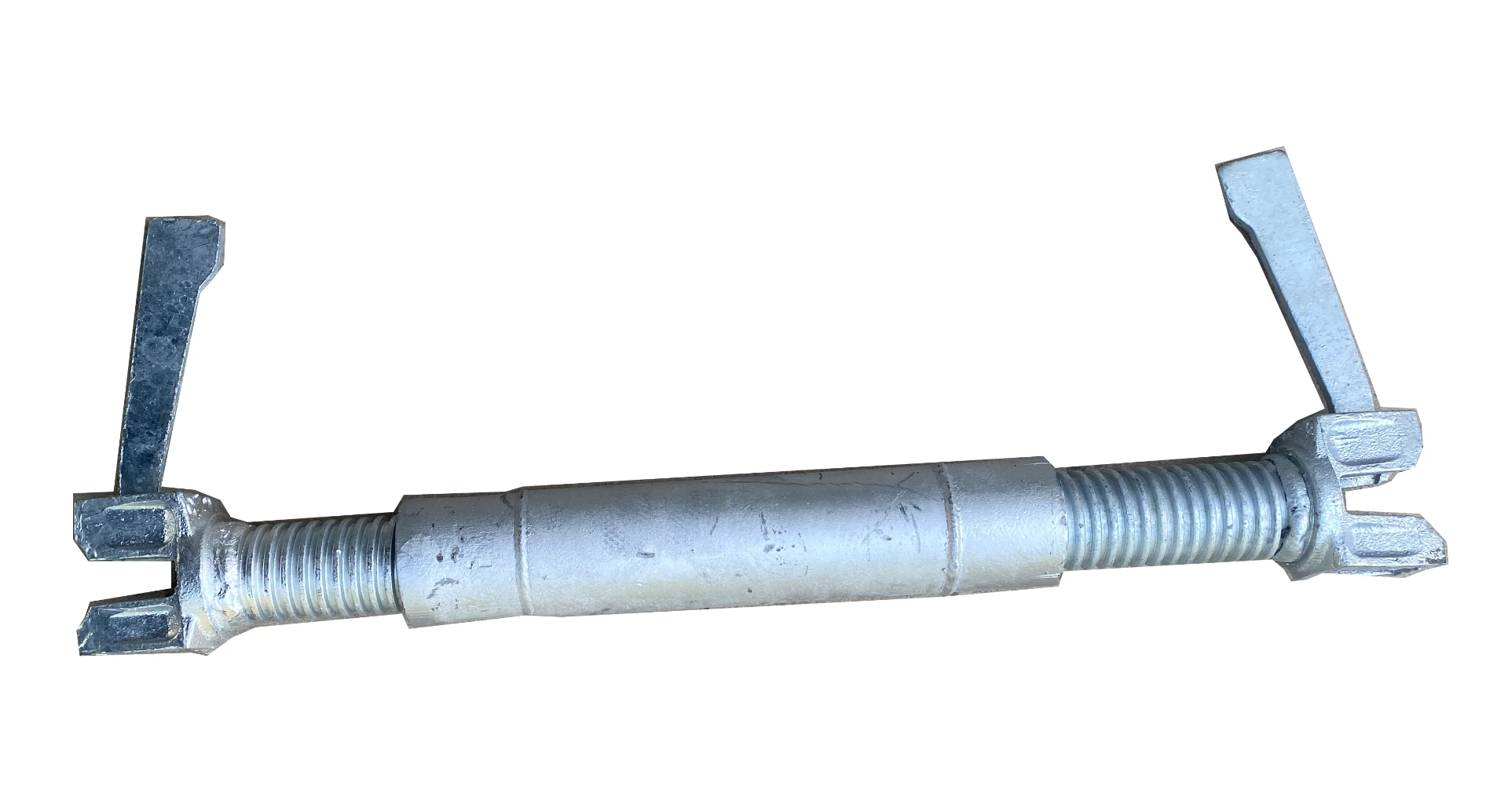

Cuplock scaffolding components: price, quality and anti-corrosive protection

6. Customization, Delivery, and Support

Scaffolding standards can be custom-engineered in diameters of 48.3/60.3mm, wall thickness 2.5–5.0mm, with robot-welded rosette spacing from 500–1000mm. Customer-specific powder color/branding, stamping, and laser-etched trace codes are standard. All products ship with unique batch QC certificates and digital inspection reports.

- Lead Time: 18–22 days upon PO/conf. for up to 3 container111s; urgent OEM up to 8 days.

- Warranty: 36 months standard (extensions up to 8 years available for certain segments).

- Support: Site assembly guidance, international engineer dispatch, 7/24 technical support lines.

- After-sales Service: 1:1 replacement for hidden manufacturing defects; on-site support available in strategic markets.

Adjustable scaffolding modular install versus traditional system

7. FAQ: Professional FAQ on Scaffolding Standards & Components

Expert Answers to Construction Professionals’ Most Searched Queries

1. What’s the primary steel grade used in scaffolding standards?

The dominant grade is Q345 (Chinese equivalent to ASTM A572 Gr.50), with ≥345MPa yield strength. Its high ductility and impact resistance are suitable for demanding site loads and impact, essential for robust scaffolding performance.

2. How is load capacity determined for adjustable scaffolding?

Load capacity is based on yield/tensile strength, tube dimensions, and node design, verified according to EN 12810 or ANSI/SSFI standards. For Standards - Early Release, safe working loads are certified up to 75 kN per vertical.

3. What testing standards are mandatory before international project supply?

Third-party inspections using EN12810 (Europe), ANSI/SSFI (USA), ISO 9001:2015 QA, and hot-dip coating per EN ISO 1461/ASTM A123 are required. Scaffolding must also undergo chemical, visual, weld, and loading cycle tests.

4. What are the best practices for preventing scaffolding corrosion?

Adopt hot-dip galvanizing (≥55μm zinc layer), use powder coatings (epoxy/polyester), and store in ventilated, covered locations. Annual inspections and repairs per ISO 16630 are also advised.

5. Are standards compatible with other modular scaffolding systems?

Yes. Most modern systems, including cuplock, ringlock, and quicklock, maintain 48.3mm/60.3mm diameters and standard rosette pitches, so Standards - Early Release offers drop-in interoperability.

6. How does aluminium scaffolding price compare with steel alternatives?

While aluminium scaffolding systems are typically 30–50% more expensive, they offer much lower weight (by >65%), faster assembly, and long-term savings in labor and logistics—justifying their price in many urban & high-altitude projects.

7. What kind of warranty and customer support is available?

All products come with a minimum 36-month structural warranty. Full documentation and global site-support are standard for project customers. Urgent replacement service covers any manufacturing defect, with remote and in-person engineering available on request.

Certified scaffolding quality inspection following ISO/EU standards

8. Why Choose Standards - Early Release?

- Precision engineered for top-tier safety & reliability in scaffolding.

- User-proven in industrial, municipal, and commercial projects worldwide.

- Outstanding anti-corrosive lifespan, meeting EN/ISO and ANSI benchmarks.

- Certified by SGS, TÜV, and CQM; full electronic documentation for every shipment.

- Seamless compatibility with all major modular scaffolding systems.

- Responsive OEM/ODM, strict batch QC, and reliable after-sales support.

Get a tailored scaffolding quotation or engineering advice for your next project.

Contact Standards - Early Release experts >>

Contact Standards - Early Release experts >>

Leading global scaffolding companies streamline modular construction

References & Further Reading

- Market Analysis: Markets & Markets Scaffolding Report 2023

- Forum: Scaffolding Engineering & Safety Forum - Eng-Tips

- Standards Reference: ANSI/SSFI SC100-5 Standard

- Technical Journal: Advances in Modular Scaffolding Systems (Advanced Engineering Informatics, 2023)

- Testing Standards: ISO 12810 Scaffolds Standard

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products