Scaffolding for Sale - Durable, Safe & Affordable Options Available

In the modern construction industry, scaffolding for sale plays a pivotal role in ensuring efficient, safe, and flexible accessibility for all types of building projects. Advances in scaffold design such as aluminium scaffolding for sale and mobile scaffold for sale are empowering contractors with robust, lightweight, and modular solutions. This article provides an in-depth analysis of the latest scaffolding technologies, manufacturing processes, technical specifications, vendor comparisons, and real-world application cases to help you make informed purchasing decisions.

1. Global Industry Trends: Scaffolding for Sale

The global market for scaffolding for sale is projected to reach USD 50.1 billion by 2030, growing at a CAGR of 5.2% (source: Grand View Research, 2023). Recent innovations such as modular aluminium scaffolding for sale and mobile scaffold for sale are significantly improving workplace efficiency and safety.

Across construction, petrochemical, water supply, shipbuilding, and energy sectors, the adoption of advanced scaffolding solutions is driven by:

- Stringent safety regulations (meeting ANSI A10.8, EN 12811 standards)

- Increasing infrastructure investments worldwide

- Preference for lightweight, corrosion-resistant materials

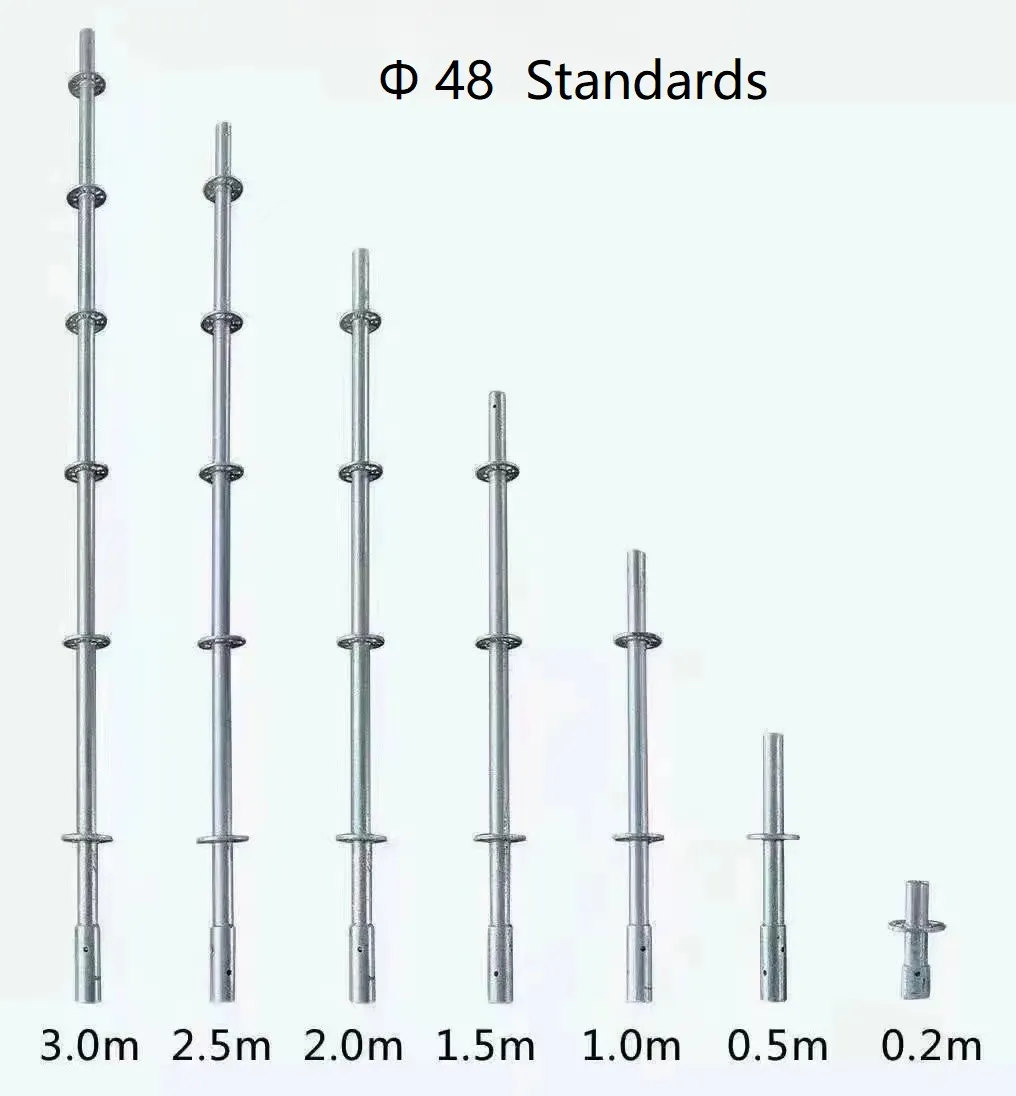

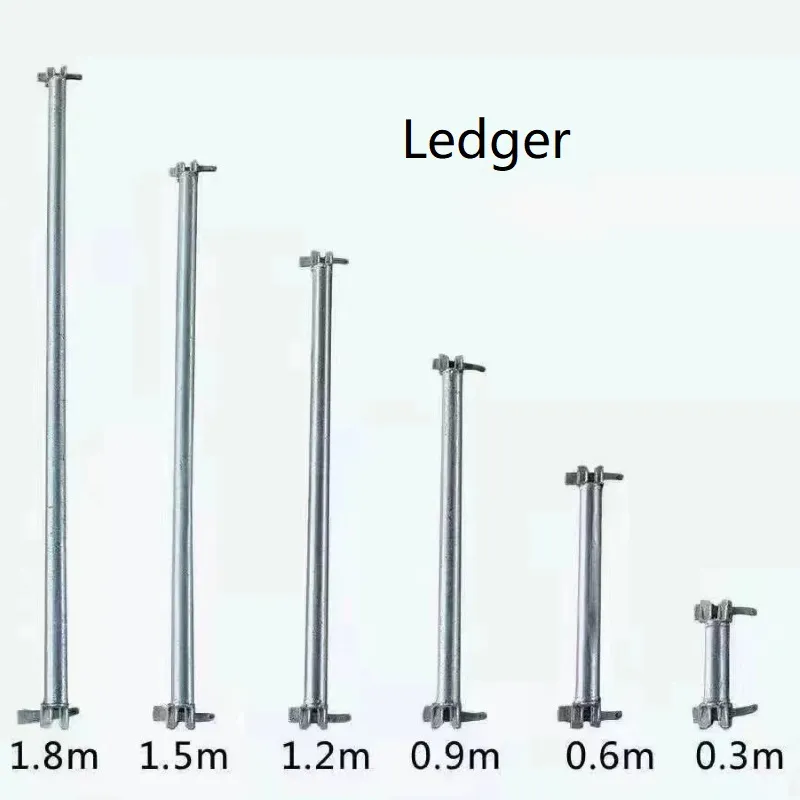

2. Technical Specifications: Comparing Top Scaffolding Products

The market includes various types of scaffolding for sale: A frame scaffold, aluminium scaffolding for sale, and mobile scaffold for sale. Choosing the right type depends on application, load capacity, site environment, and regulatory compliance.

| Specification | A Frame Scaffold | Aluminium Scaffolding | Mobile Scaffold | Steel Tube Scaffolding |

|---|---|---|---|---|

| Material | High-Strength Steel | 6061-T6 Aluminium Alloy | Aluminium & Steel | Q235/Q345 Hot-dip Steel |

| Max. Load | 200~300kg/m² | 250kg/m² | 230kg/m² | 270~350kg/m² |

| Standard Size | 1700x1219mm | 1300x750mm | 1350x750mm | Customized |

| Weight | 23kg/meter | 11kg/meter | 12~15kg/meter | 25~28kg/meter |

| Corrosion Resistance | Galvanized | Anodized | Anodized/Galvanized | Galvanized |

| Service Life | 10~15 years | 10 years | 8~12 years | 8~20 years |

| Standard Compliance | ANSI, EN, ISO | ISO 9001, EN 12811 | ANSI A10.8 | EN12810, ISO 9001 |

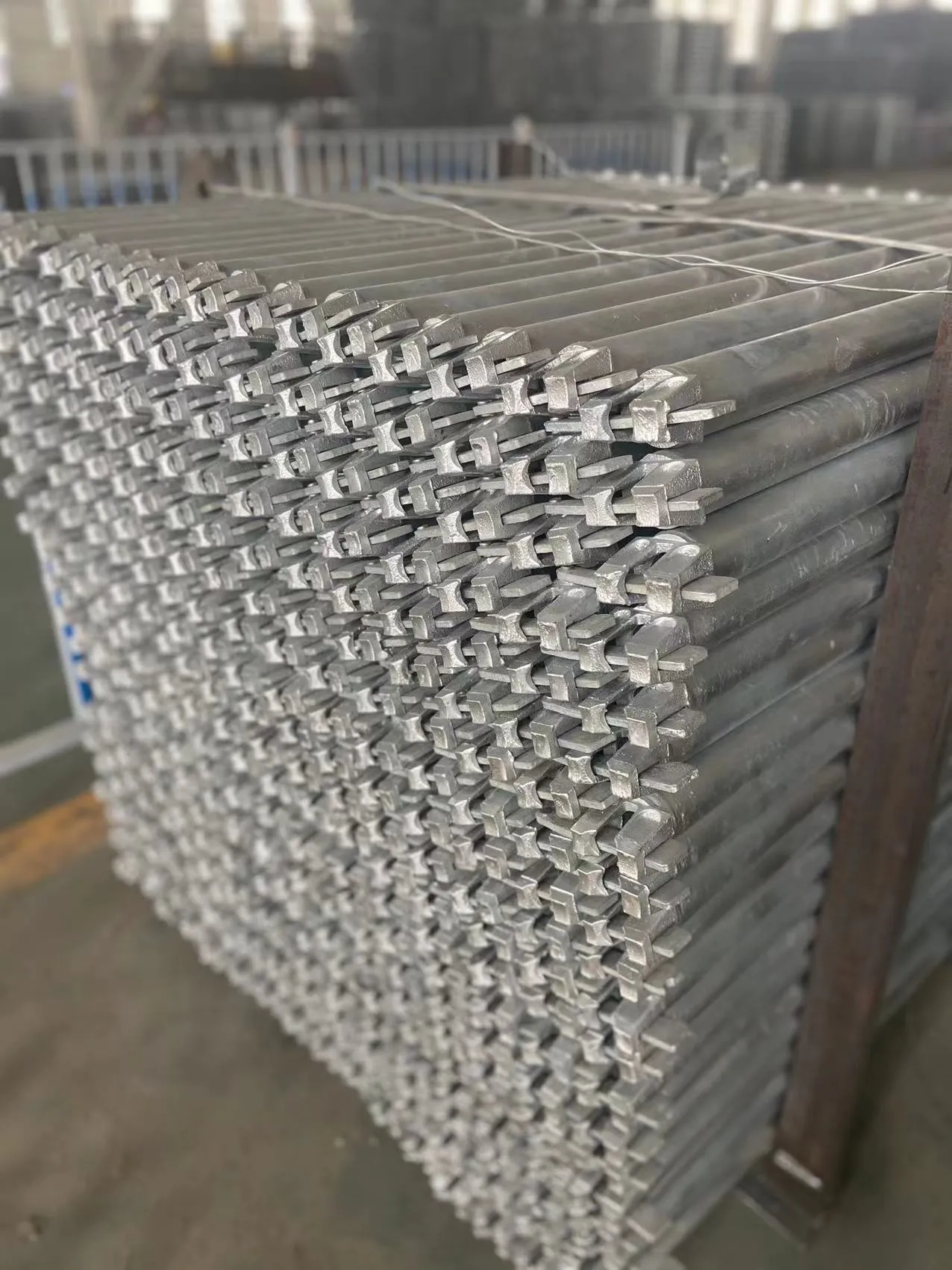

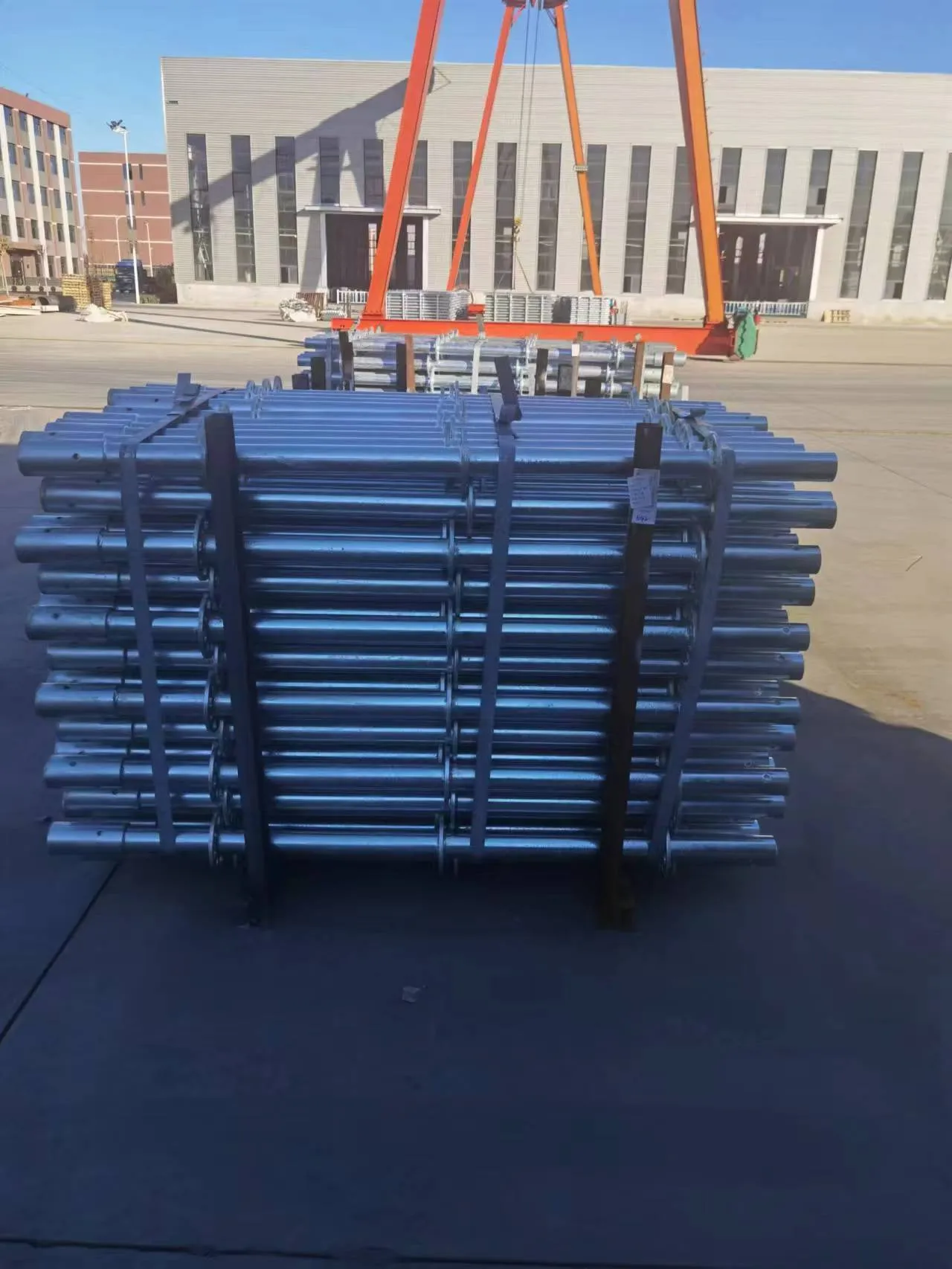

3. Scaffolding for Sale - Product Technology & Manufacturing Process

The scaffolding for sale by leading manufacturers undergoes a rigorous and standardized production process, ensuring premium quality, reliability, and safety for diverse construction scenarios.

4. Key Technical Indicators: Data Visualization

5. Key Applications: Industry Use Cases & Benefits

Adoption of scaffolding for sale technologies such as aluminium scaffolding and a frame scaffold in tier-1 urban centers improves installation efficiency by 37%, lowers labor costs, and supports strict safety management (ISO 9001/ANSI compliant).

Customized mobile scaffold for sale used in oil refineries and large plant turnarounds offers superior corrosion resistance, weatherability, and quick relocation for dynamic site demands.

Lightweight anodized aluminium scaffolding enables safe, repeatable access in damp and chemically aggressive environments.

- Industry certifications: ISO 9001, EN12811, ANSI A10.8, SGS tested

- Major clients: Sinopec, Vanke, China State Construction, GE

- Imported to 40+ countries with >95% on-time delivery rate

6. Manufacturer Comparison: Scaffolding Suppliers at a Glance

| Supplier | Location | Main Products | Certifications | MOQ | OEM/ODM | Key Clients |

|---|---|---|---|---|---|---|

| Formwork Reinforced | China | Ringlock, Cuplock, Aluminium, A Frame, Mobile scaffold | ISO9001, EN12811, ANSI, SGS | 100 m² | Yes | Vanke, Sinohydro |

| ULMA Construction | Spain | Aluminium & Modular Scaffolding | ISO9001, EN | 300 m² | Yes | Ferrovial |

| PERI Group | Germany | Steel & Aluminium Scaffolding | ISO, DIN | Flexible | Yes | Bouygues |

| Layher | Germany | All Types | ISO, EN12811 | 200 m² | No | Skanska |

7. Custom Scaffolding Solutions: Design to Delivery

- Free technical consultation & on-site project survey

- Kiln-dried durable timber planks or anti-slip steel platforms

- Integrated safety rails, toe boards, access ladders

- Modular connection: pinlock, cuplock, ringlock, A frame

- Bespoke hot-dip galvanization or anodizing per project specs

- EU/US export packing, logistics tracking, one-stop solution

8. Service & Support Commitment

- Lead time: Standard scaffolding for sale products: 7-10 working days for orders <5000m²; 18-25 days for custom bulk

- Warranty: 5 years, extends to 10 years for premium lines

- Global technical support: 24/7, on-site assist in 30+ countries

- After-sales: Free installation training, video guides, quick replacement parts within 48 hours

- Third-Party Inspections: SGS/BV/Intertek

9. Professional FAQ on Scaffolding for Sale

10. Conclusion & Authoritative Reference

As demonstrated above, modern scaffolding for sale solutions integrate advanced materials, precision manufacturing, and international certifications to deliver safety and performance for any project. Whether you require a frame scaffold, mobile scaffold for sale, or high-strength aluminium scaffolding for sale, select vendors with robust QA processes, global references, and documented compliance.

For further technical insights and compliance advice, see:

- Scaffolding for Sale Product Page

- Scaffolders Forum

- Scaffold Industry Standards Explained

- [MDPI Applied Sciences] Optimization of Scaffolding Systems

[1] Grand View Research. "Scaffolding Market Size, Share & Trends Analysis Report 2023-2030".

[2] "Scaffolders Forum" : https://www.scaffoldersforum.com/

[3] MDPI Appl. Sci. 2021, 11, "Scaffolding System Optimization": View journal

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025