Imagine this: 74% of construction incidents occur due to faulty or improper scaffolding fittings. That's right. One poorly secured joint pin scaffolding structure could mean spiraling project delays, injuries, or even fatal disasters.

What if you could cut that risk to almost zero?

Discover how the right scaffolding pipe joint clamp

rewrites the rules of safety, efficiency, and cost-performance. You’re about to rethink how simple hardware makes a massive difference.

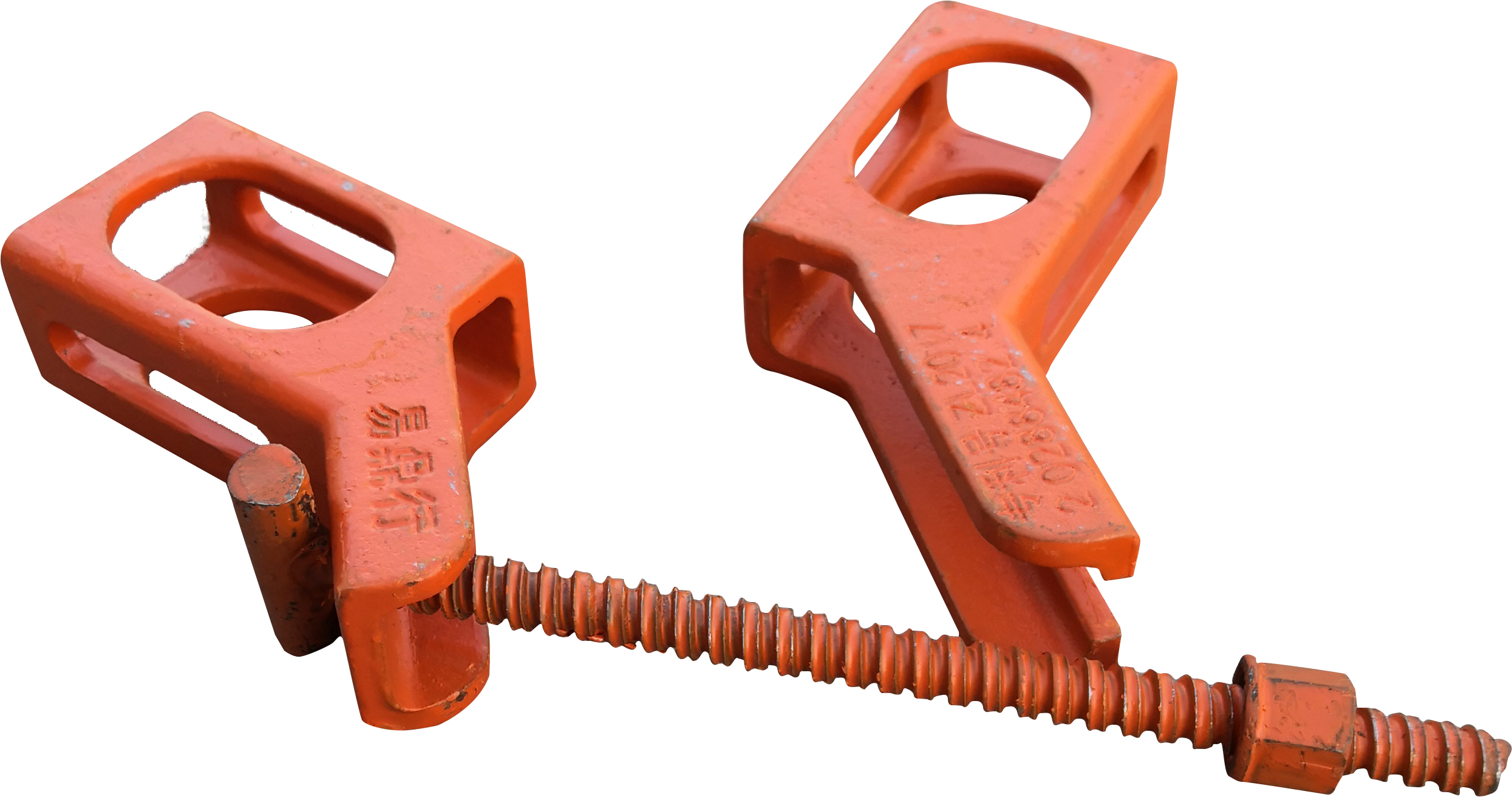

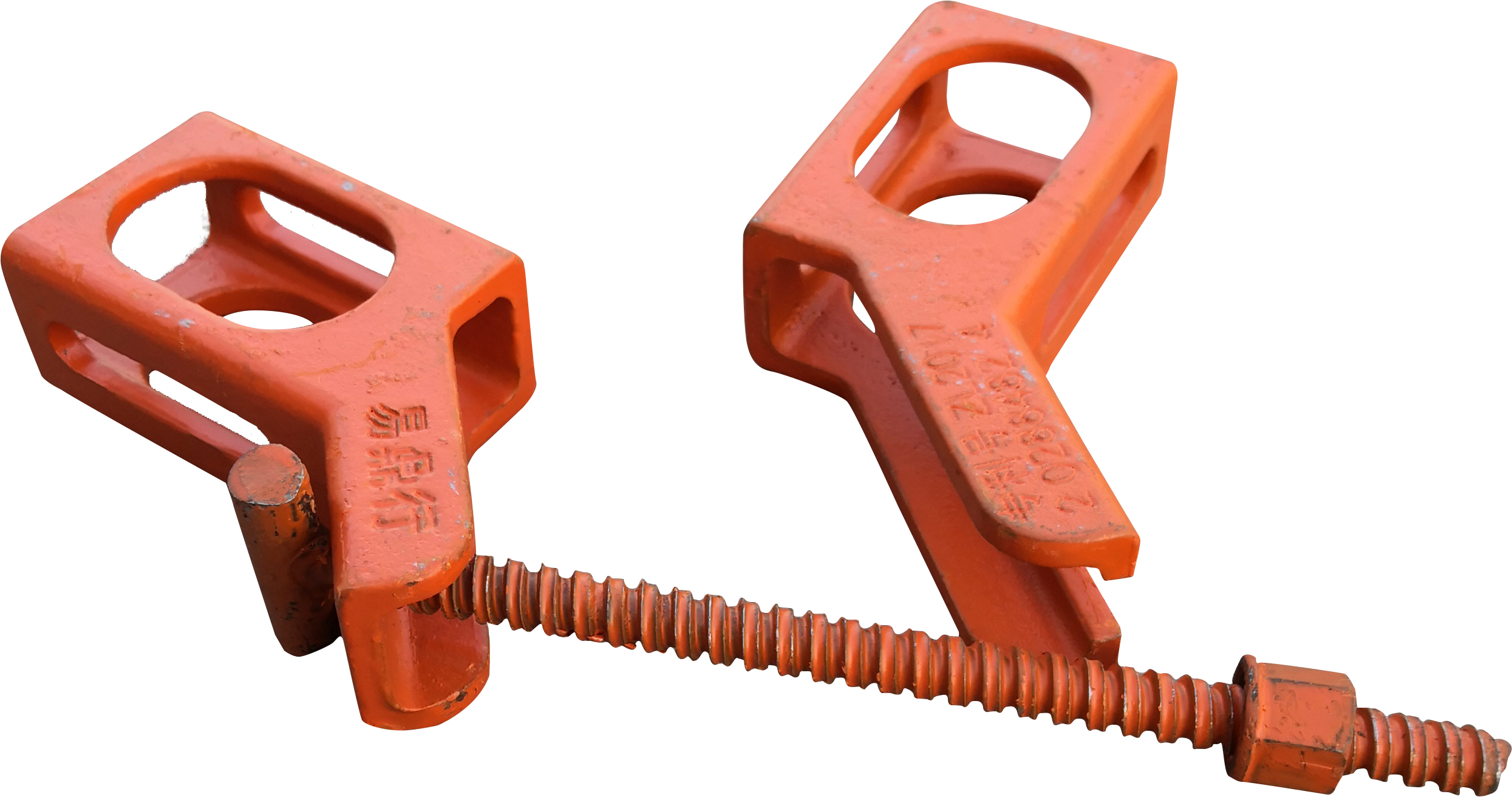

(scaffolding pipe joint clamp)

Why Choose Top-Grade Scaffolding Pipe Joint Clamps?

Not all clamps are made equal. Our scaffolding pipe joint clamps combine strength, durability, and quick installation. Each clamp handles up to 6.5kN of load—double the international minimum safety standard. Zinc-plating resists corrosion for over 72 hours of salt-spray testing. You never have to worry about rust or premature failure.

| Feature |

Industry Standard |

Our Clamp |

| Safe Working Load |

3.2kN |

6.5kN |

| Corrosion Protection |

24 Hours |

72+ Hours |

| Install Speed |

4 min/joint |

1.5 min/joint |

Need to upgrade safety? Demand less downtime? Our clamps deliver both.

Supplier Showdown: Why Our Joint Pins & Clamps Stand Out

You have choices in today’s market. But here’s the twist: few offer transparency on joint pin scaffolding price or strict QC on the scaffolding pipe joint pin itself.

- 100% batch-tested for safety

- Consistent dimensions: 48.6mm pipe fit ± 0.2mm

- Ambiguous pricing? Not here. We list competitive rates right up front: From $0.70 per clamp—bulk deals, always.

- Global certifications: ISO, EN74, JIS G3444

- Seamless logistics to 25+ countries

We believe in open dealing and real numbers. Why trust the build that holds lives on empty claims? Choose proof, not promises.

Custom Scaffolding Joint Solutions—Just for You

Projects differ. So should your scaffolding hardware. We offer:

- Pipe joint clamps from 38mm up to 76mm diameter

- Steel grades Q235B, Q345, and optional HDG

- Custom branding, color marking, and barcoding for asset tracking

- Pre-assembled or knock-down sets

- OEM/ODM capability—perfect fit, every time

No two jobs are the same. Let’s find the perfect clamp for your specs, timeline, and safety code. Premium custom. Zero premium headaches.

Proven Success: Real-World Application Cases

Numbers tell the story, but our clients shout the results.

Case Study: Metro Tower, Kuala Lumpur

Problem: The project faced a 22% delay due to unstable pipes and mismatched joint pins.

Solution: Our team delivered 25,000 custom joint clamps (48.6mm, zinc-plated). Fitment rate? 99.8%. No failures. Installation time cut by 60%.

Result: Project caught up and finished ahead by 14 days, at a cost savings of $18,500.

Trusted in 12 Major Countries

From US skyscrapers to highways in Dubai, our scaffolding pipe joint clamps support safer, smarter builds all over the globe. Want reliability? Here’s where it begins.

Ready for Better, Safer, Faster Scaffolding?

At ZENITH ScaffoldTech, we blend engineering rigor with unbeatable prices. Our scaffolding pipe joint clamps and joint pins are trusted by industry leaders worldwide. Want bulk pricing? Custom logos? Real-time shipping? You’ve found your source.

Don’t let faults and delays threaten your project—switch to the industry’s 1 joint clamp solution now!

Contact Our Engineers Today – Get a FREE Quote!

(scaffolding pipe joint clamp)

FAQS on scaffolding pipe joint clamp

Q: What is a scaffolding pipe joint clamp used for?

A: Scaffolding pipe joint clamps are used to connect two scaffolding pipes together securely. They ensure the structural stability of the scaffolding. This allows for safe and flexible construction setups.

Q: How is a scaffolding pipe joint pin different from a pipe joint clamp?

A: A scaffolding pipe joint pin is inserted inside the pipes to join them end-to-end. In contrast, a joint clamp holds pipes together externally. Both are essential for assembling safe scaffolding structures.

Q: What factors affect the joint pin scaffolding price?

A: The price of joint pin scaffolding depends on material quality, size, and manufacturing standards. Bulk purchase and brand reputation can also impact cost. Always compare different suppliers for the best rates.

Q: Are scaffolding pipe joint clamps reusable?

A: Yes, most scaffolding pipe joint clamps are made from durable steel for repeated use. They can be easily attached and detached as needed. Regular inspection for damage is recommended.

Q: Can I use a scaffolding pipe joint clamp for all types of scaffolding pipes?

A: Scaffolding pipe joint clamps are designed for specific pipe diameters and types. Always check compatibility with your scaffolding system. Using the wrong clamp may compromise safety.