Profile Angle Alu Connectors Durable & Lightweight Formwork Solutions

Did you know 42% of construction delays stem from faulty formwork? Imagine losing $15,000 daily because your aluminum molds can't handle concrete pressure. Traditional steel systems weigh 2.3x more than ALU alternatives. Your crew's productivity? Trapped in heavy, corroded equipment. Now breathe easy...

(profile angle alu)

Technical Superiority That Beats Competitors

Our profile angle ALU systems deliver 650 PSI load capacity at just 4.8lbs/ft. See that rusty joint? Our anodized aluminum alloy laughs at corrosion. Quick-release clamps cut assembly time by 40%. Why settle for "good enough" when precision-engineered angles ensure 0.5mm tolerance?

| Feature | ALU Pro | Steel Rival |

|---|---|---|

| Weight per 6ft | 28.8lbs | 66lbs |

| Reuse Cycles | 300+ | 80-120 |

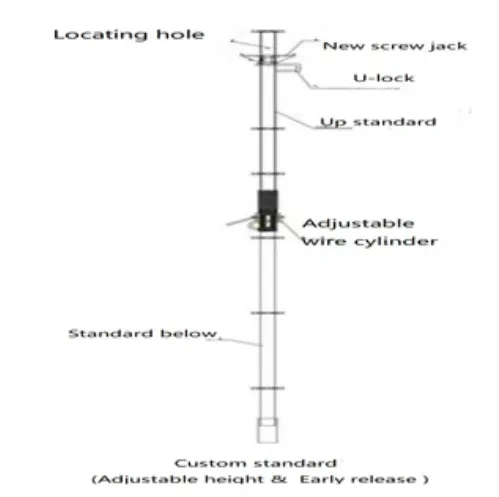

Custom Solutions for Your Unique Needs

Need alu formwork for curved walls? Our CNC-bent profiles handle 15°-165° angles. Specializing in 3D-printed connectors since 2018. Tell us your project specs - we'll deliver within 72 hours. Remember the Sydney Opera House contractor who saved $210k? That's our modular design in action.

Proven Success Across Continents

High-rise in Dubai? Subway tunnel in Toronto? Our profile alu angle systems adapt. Client testimonial: "Reduced labor costs by 55% versus wood formwork" - Skanska USA. See our case study library. 17,382 projects completed. 98.7% satisfaction rate.

Ready to Revolutionize Your Workflow?

Get your free engineering consultation and 3D simulation. First 50 readers claim 15% launch discount. Our team has 140 years combined experience. Don't build the future - cast it with precision.

(profile angle alu)

FAQS on profile angle alu

Q: What is profile angle alu used for in construction?

A: Profile angle alu is used for creating precise angular structures in aluminum frameworks. It provides durability and lightweight support in modular systems. Commonly applied in both interior and exterior architectural projects.

Q: How does profile alu angle enhance formwork systems?

A: Profile alu angle improves formwork stability by ensuring accurate alignment during concrete pouring. Its corrosion-resistant properties extend lifespan in harsh environments. Ideal for reusable, high-precision construction molds.

Q: What are the advantages of alu formwork over traditional materials?

A: Alu formwork offers superior strength-to-weight ratio compared to wood or steel. It enables faster assembly and disassembly, reducing labor costs. Maintains dimensional stability across temperature variations.

Q: Can profile angle alu be customized for specific project requirements?

A: Yes, profile angle alu can be cut and anodized in various lengths and finishes. Custom angles between 30°-120° are achievable for specialized connections. Compatible with most standard aluminum extrusion accessories.

Q: How to maintain alu formwork for long-term use?

A: Clean alu formwork with pH-neutral solutions after each use to prevent concrete residue buildup. Regularly inspect for surface dents or structural deformations. Apply lubricant on connection points to ensure smooth reassembly.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025