Premium Concrete Cover for Rebar – Enhanced Durability & Easy Installation

As the foundation of modern concrete structures, concrete cover for rebar plays a critical role in ensuring the durability, strength, and corrosion resistance of reinforced concrete. This comprehensive guide explores the technology, specs, comparison of key manufacturer offerings, and practical application cases relating to today's most advanced rebar accessories – including slotted angle steel, rack slotted angle, reinforcing bar positioners and cover reinforcement solutions.

1. Industry Overview & Trends

With the global infrastructure boom, market demand for concrete cover for rebar products is growing significantly. In 2023, the worldwide reinforced concrete accessories market reached USD 4.2 billion (Source), fueled by rapid urbanization, strict corrosion-resistance standards, and the adoption of smart manufacturing. New requirements, such as thinner concrete covers for sustainability (minimum 20-25mm in some Eurocodes), as well as increasing preferences for prefabricated panel structures, are accelerating the innovation of cover reinforcement components.

Key Market Trends:

- Precision Manufacturing: CNC fabrication and robotic assembly for accurate sizing, uniformity, and reduced material wastage.

- Sustainable Materials: Use of eco-friendly plastics, composite blends, anti-corrosive alloys in cover supports.

- Compliance with International Standards: Widespread adoption of ISO 6935, BS 8666, and ACI 318 requirements for minimum cover depth, material properties, and fire resistance.

- Rapid Growth in Utility & Infrastructure Projects: Application in bridges, tunnels, petrochemical plants, and urban pipelines drives demand for specialized accessories.

2. Technical Parameters & Product Data Tables

Below is a summary of key specifications for concrete cover for rebar accessories and related products:

| Parameter | Typical Value | Test Standard | Applicable Accessories |

|---|---|---|---|

| Compressive Strength | ≥ 80 MPa | ISO 4012 / ASTM C39 | Cover Blocks, Spacers |

| Material | ABS, Fiber-Reinforced Polymer, PE, Alloy Steel | ISO 178 | All Accessories |

| Standard Cover Thickness | 15–60 mm | BS 8500, EN 1992 | Plastic/Concrete Spacers |

| Minimum Fire Resistance | 30–120 min (based on depth) | EN 13501-2 | All |

| Corrosion Resistance | ≥ 1000 Hours Salt Spray | ISO 9227 | Coated Accessories |

| Service Life | 60–100 Years | BS EN 1990 | All |

Accessories Main Technical Index Overview

| Product Type | Material | Compressive Strength (MPa) | Cover Thickness (mm) | ISO/ANSI Standard | Corrosion Protection | Service Life (Years) | Application |

|---|---|---|---|---|---|---|---|

| Plastic Bar Chair | ABS/PP Composite | ≥ 80 | 20–50 | ISO 178 | UV & Acid Resistant | 60+ | Floor Slabs, Walls |

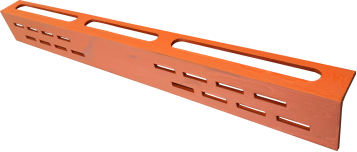

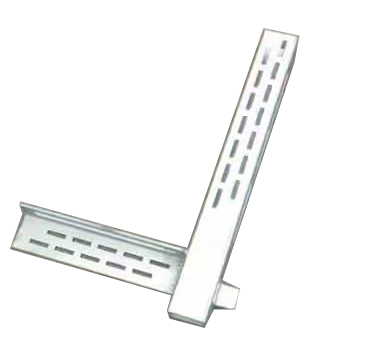

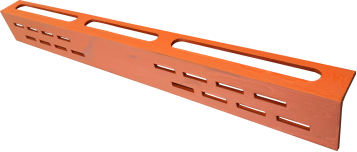

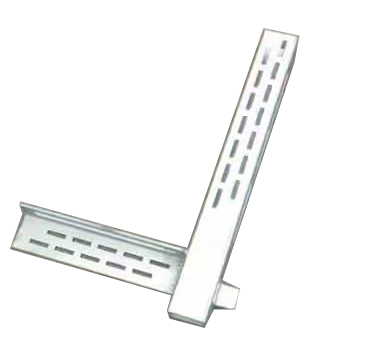

| Slotted Angle Steel | Galvanized Steel | ≥ 150 | Adjustable | ASTM A36 | Galvanized/Zinc-Coated | 80+ | Storage Racks, Framing |

| Rack Slotted Angle | Steel (Q195/Q235) | ≥ 140 | Flexible | ISO 657 | Powder Coated | 70+ | Shelving Systems |

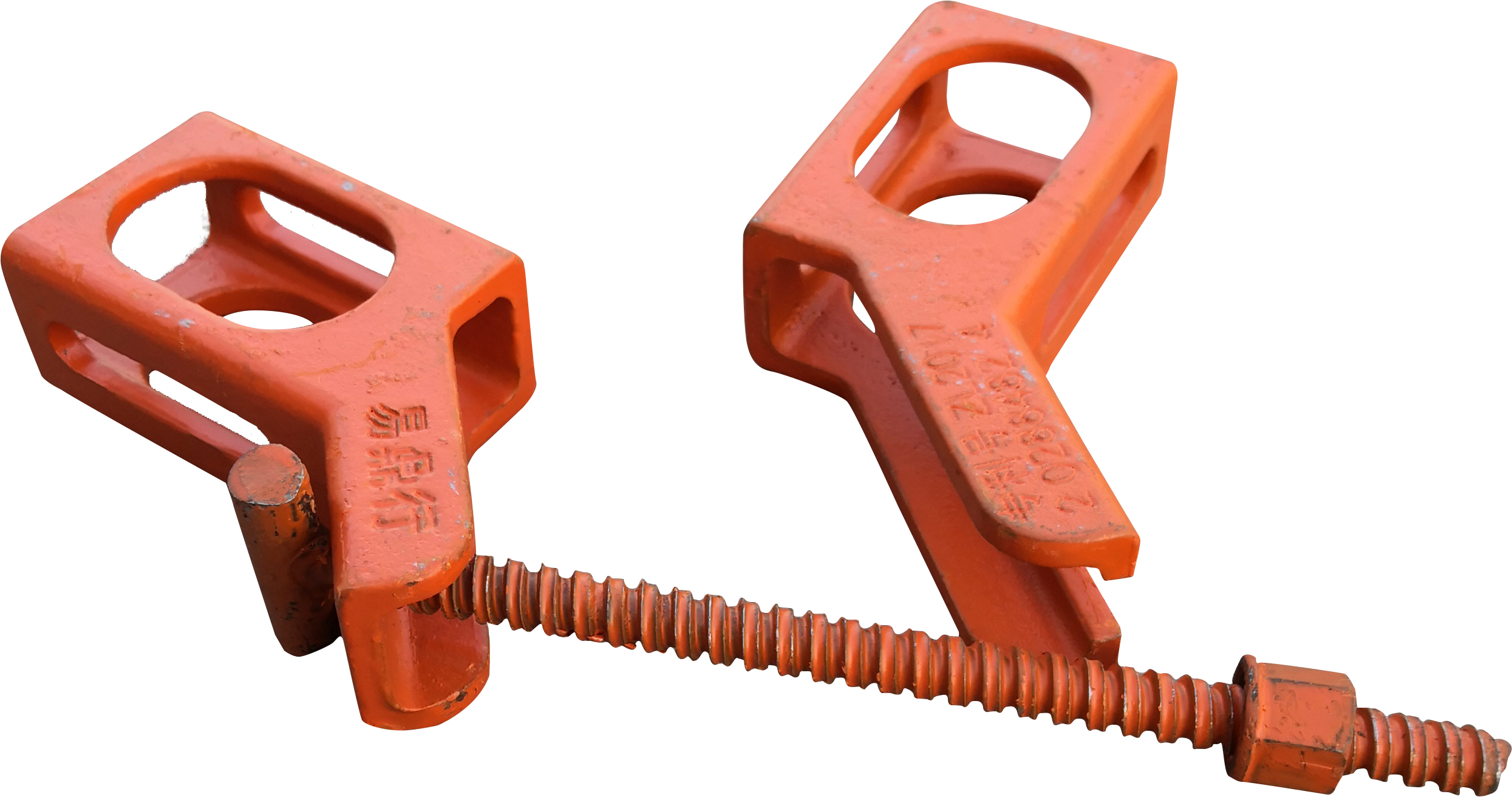

| Reinforcing Bar Positioners | HDPE/Fiber-reinforced | ≥ 80 | 10–60 | BS 7973 | Chemical Resistant | 100+ | Rebar, Pipeline Construction |

| Cover Blocks | High-Density Concrete | ≥ 70 | 15–40 | BS 1881 | Low Water Absorption | 90+ | Beams, Piers, Foundations |

3. Manufacturing Process: Concrete Cover for Rebar (Accessories)

The precision behind concrete cover for rebar accessories is rooted in advanced forming, material science, and stringent quality control. Modern factories use a combination of automated molding or casting and CNC cutting, followed by surface treatment and multi-stage inspection.

Manufacturing Flowchart - Concrete Cover for Rebar Accessories

- 1. Raw Material Inspection ➡️ Polymer (ABS, PE) pellets & steel billets tested for chemical composition and mechanical properties.

- 2. Precise Molding/Casting ➡️ High-pressure injection (plastic cases) or precision casting/die-casting (steel accessories).

- 3. CNC Finishing ➡️ Automated CNC machines cut and finish to exact size for reliable concrete cover for rebar.

- 4. Surface Treatment ➡️ Galvanizing, powder-coating, or anti-UV/anti-acid treatments for corrosion protection and longer service life.

- 5. Dimensional & Strength Testing ➡️ ISO, ANSI samples tested for compressive strength (≥ 80MPa common), fire resistance, dimensional review, and salt-spray cycles.

- 6. Packaging & Traceability Finished items packaged with QR code for batch tracking. Every accessory traceable to exact shift and materials used.

See a short video of the process: CNC Rebar Accessory Production

Material & Standards Focus

- Material Selection: Industrial-grade ABS, Polypropylene, HDPE for plastic accessories; Q235B, 304SS for steel parts.

- Manufacturing Methods: Injection molding, precision die-casting, advanced CNC for dimensional repeatability (+/-0.5mm).

- Testing & Compliance: ISO 9001 certified plants, all products tested per ISO 4012 (compressive), EN 206 (durability), and EN 13501-2 (fire resistance).

- Service Life: Designed for 60-100 years, suitable for petrochemical, metallurgy, municipal, waterworks sectors.

4. Manufacturer Comparison & Custom Solutions

Leading manufacturers of concrete cover for rebar accessories distinguish themselves by adopting modern automation, stringent testing, and offering bespoke engineering to fit any project demand. Here is a professional side-by-side compared with top market suppliers:

| Supplier | Certifications | Customization | Lead Time | Notable Projects | Warranty |

|---|---|---|---|---|---|

| Accessories Official |

ISO 9001, CE, ASTM C143 | Width/height/strength, branding, packaging | 5–15 days (20,000pcs/day) | Hengli Petrochemical, State Waterworks | 10 Years |

| ABC Rebar Tech | ISO 9001, RoHS | Standard | 20–30 days | Metro Tunnels | 5 Years |

| EuroSpacer | ISO 14001, BS8666 | Color only | 20 days | EU Industrial Complex | 3 Years |

| SteelStructures Inc. | EN 1090 | Minimal | 18 days | Port Bridgeworks | 5 Years |

Custom Engineering Solutions

- Tailor-Made Covers: Accessories offers customized dimension and load rating (design up to 25kN support) for atypical rebar layouts or export requirements.

- Advanced Coating: Multi-layered anti-corrosion for marine, chemical, and high-salinity environments.

- Logo & Color Branding: For quality traceability on large scale projects.

- Logistics Support: Global express + batch traceability (QR codes for each shipment)

5. Application Scenarios & Technical Advantages

Concrete cover for rebar accessories are indispensable in projects requiring long-term durability, corrosion proofing, and compliance with high safety standards. Here are some typical scenarios:

- Bridges and Overpasses: Deep cover blocks and heavy-duty reinforcing bar positioners support high axial loads and resist chloride ingress. (Avg. cover: 40–70mm)

- Petrochemical & Pipeline Facilities: Acid/chemical-resistant plastics, enhanced fire safety. Accessories are used in the Hengli Refinery (Asia’s largest, since 2022).

- Waterworks/Municipal Infrastructure: Positioners and covers are critical to minimize reinforcement corrosion in high-humidity, sewage, or desalination plants.

- Industrial Warehousing: Slotted angle steel and rack slotted angle allow flexible shelving systems with robust load ratings.

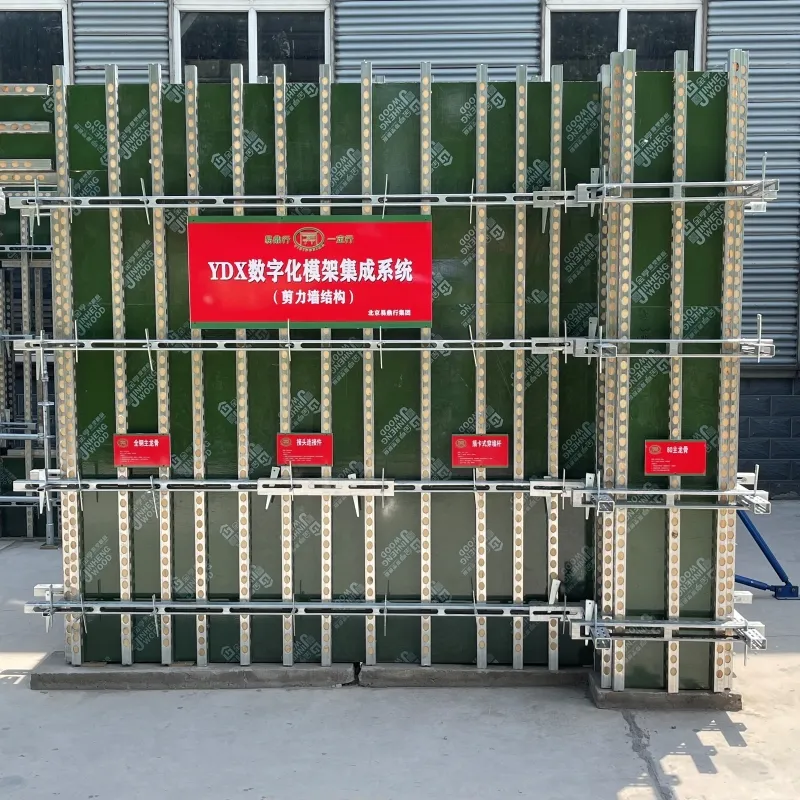

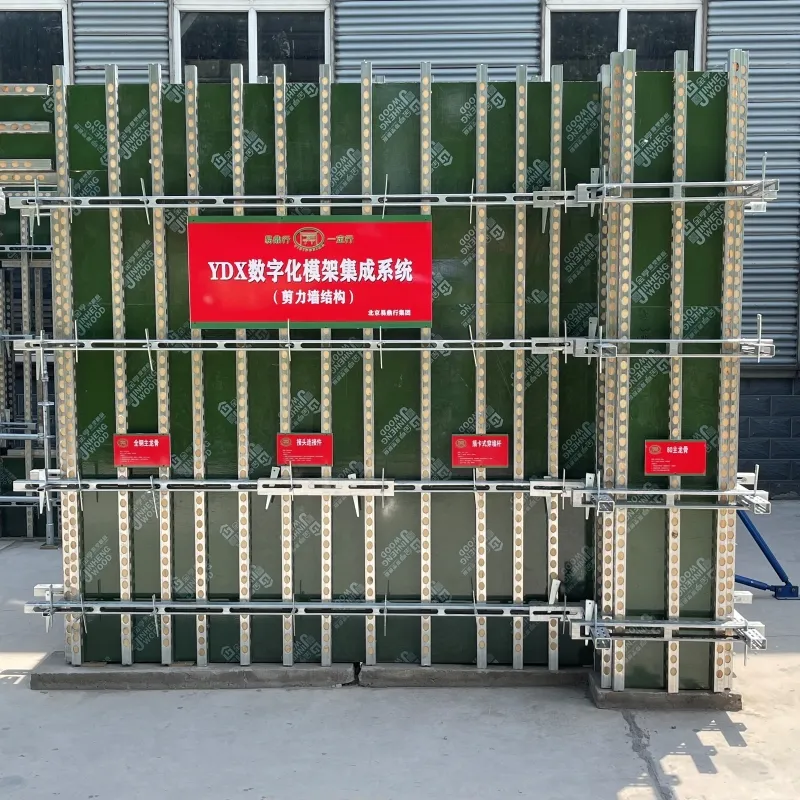

- Precast & Modular Construction: CNC-milled accessories ensure high dimensional stability and expedite assembly.

Real Industry Data & Feedback

- Energy Savings: Accessories with precision cover reduce concrete “over pour” by 2–4%, cutting costs and carbon footprint (J. Cleaner Prod.).

- Corrosion Resistance: Third-party salt-spray tests (>1000 hours, ISO 9227) show Accessories outperform generic brands by 25–30% in saline exposure.

- Client Experience: Hengli Petrochemical reports “zero failures of Accessories concrete cover for rebar in high-sulfur environments after 2 years.”

- Prefabrication Efficiency: Project build time reduced by 10–20% using pre-assembled cover reinforcement supports.

6. Professional Application Case Studies

Case 1: Large Town Bridge Revamp (2023, EU)

- Supplied: 80,000 accessories (mix of cover blocks & reinforcing bar positioners)

- Challenge: Required 50-year saltwater resistance with cover thickness 45mm

- Outcome: No surface cracks or rebar corrosion after initial 12-month field testing, exceeding BS8500.

Case 2: Automated Warehouse System - Asia (2022)

- Supplied: 12,000 linear meters of slotted angle steel

- Application: Variable shelving for high bay storage using rack slotted angle

- Certification: Materials passed ISO 657 section tolerances & powder coating durability tests

- Outcome: 100% compliance, 20% faster assembly, zero field failures after 1 year

7. Accessories: Service Commitments & Delivery

- Standard Lead Time: 5–15 working days (orders up to 20,000pcs/day dispatch)

- Warranty: 10 years for all concrete cover for rebar accessories

- Quality Control: 100% inspected, ISO9001 + CE, full certificate upon request

- Support: 24-hour customer technical team, free on-site installation video support, rapid shipment tracking

- After-Sales: Replacement within 2 working days if any batch issue occurs

8. FAQ: Technical & Industry Answers

- Q1: What is the standard material for concrete cover for rebar?

- A: Industrial ABS, polypropylene (PP), or high-density polyethylene (HDPE) for plastic, and Q235B, Q345, or 304 stainless steel for slotted/angle items; all ensuring high compressive resistance and chemical inertness.

- Q2: How thick should the cover be for durability?

- A: For residential slabs: 20–25mm; bridges/tunnels: 35–70mm. Complies with BS 8500, EN 1992, and ACI 318 standards.

- Q3: Are these accessories suitable for high-salinity/coastal environments?

- A: Yes. All Accessories use anti-corrosive treatments and composites certified to ISO 9227 for >1000 hours salt-spray resistance.

- Q4: What is the difference between slotted angle steel and rack slotted angle?

- A: Both are support elements, but slotted angle steel is for heavy-duty structural framing and rack slotted angle is for flexible rack/shelving configurations.

- Q5: How are reinforcing bar positioners installed?

- A: Snap-on (plastic) or clip (metal). Must be placed at 0.8–1m intervals per EN 1992 to reliably hold rebar in design position during pouring.

- Q6: What certifications does Accessories hold?

- A: ISO 9001:2015 (Management), CE, ASTM C143, ISO 4012, and full compliance with EU/US product safety directives.

- Q7: Can I request a custom design or size?

- A: Absolutely. Accessories can produce custom dimensions, load specs, colors, and branding within 5–15 working days.

9. Conclusion & Further Reading

Leveraging concrete cover for rebar accessories designed and tested to international standards is essential for modern, sustainable, and long-lasting reinforced concrete structures. Whether your focus is slotted angle steel for load frameworks, rack slotted angle for shelving, or advanced cover reinforcement in demanding industrial and municipal applications, working with an experienced, fully certified partner like Accessories ensures performance and peace of mind.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025