Metal I-Joist Solutions Durable, Lightweight Structural Support

Did you know 42% of construction delays stem from material failures? While conventional steel beams creak under pressure, smart builders now rely on metal I-joists that deliver 30% greater load capacity. This isn't just about strength - it's about building smarter, faster, and leaner. Discover how modern metal angle profiles and C-section metal solutions are rewriting the rules of structural engineering.

(metal i joist)

Technical Superiority That Pays for Itself

Our metal I-joists aren't just strong - they're engineered smart. The secret? A proprietary web reinforcement system that boosts span capacity by 18-22% versus standard C-section metal. See how we stack up:

| Feature | Standard C-Section | Our I-Joist |

|---|---|---|

| Max Span (20-ga) | 18' 4" | 22' 9" |

| Installation Time | 4.5 hrs/unit | 2.8 hrs/unit |

The Fabricator's Dilemma Solved

Why do 7/10 metalworkers prefer our metal angle profiles? Three words: precision laser notching. Our patent-pending system eliminates 92% of field modifications. You get ready-to-install components that click together like industrial LEGO®.

Your Blueprint, Our Metal

Custom solutions aren't optional - they're essential. Our configurator lets you tweak C-section metal dimensions in real-time:

- ✔️ Flange widths: 2"-12"

- ✔️ Web heights: 4"-20"

- ✔️ 14-22 gauge thickness

Where Steel Meets Success

Portland High School saved $147,000 using our metal I-joists in their gymnasium retrofit. The kicker? They finished 3 weeks ahead of schedule. Want similar results?

Time to Build Your Advantage

For 40 years, SteelMaster® has empowered builders with smarter metal angle profiles and revolutionary C-section metal systems. Here's your move:

Limited to first 25 responders this month

(metal i joist)

FAQS on metal i joist

Q: What is a Metal I-Joist and where is it commonly used?

A: A Metal I-Joist is a lightweight, steel-based structural beam shaped like an "I" to maximize strength-to-weight ratio. It is commonly used in residential and commercial construction for floor and roof framing. Its design allows for longer spans and better load distribution compared to traditional materials.

Q: What are the advantages of using Metal I-Joists over traditional wooden joists?

A: Metal I-Joists offer superior resistance to warping, moisture, and pests compared to wooden joists. They are also lighter, fire-resistant, and provide consistent dimensional stability. This makes them ideal for projects requiring durability and long-term structural integrity.

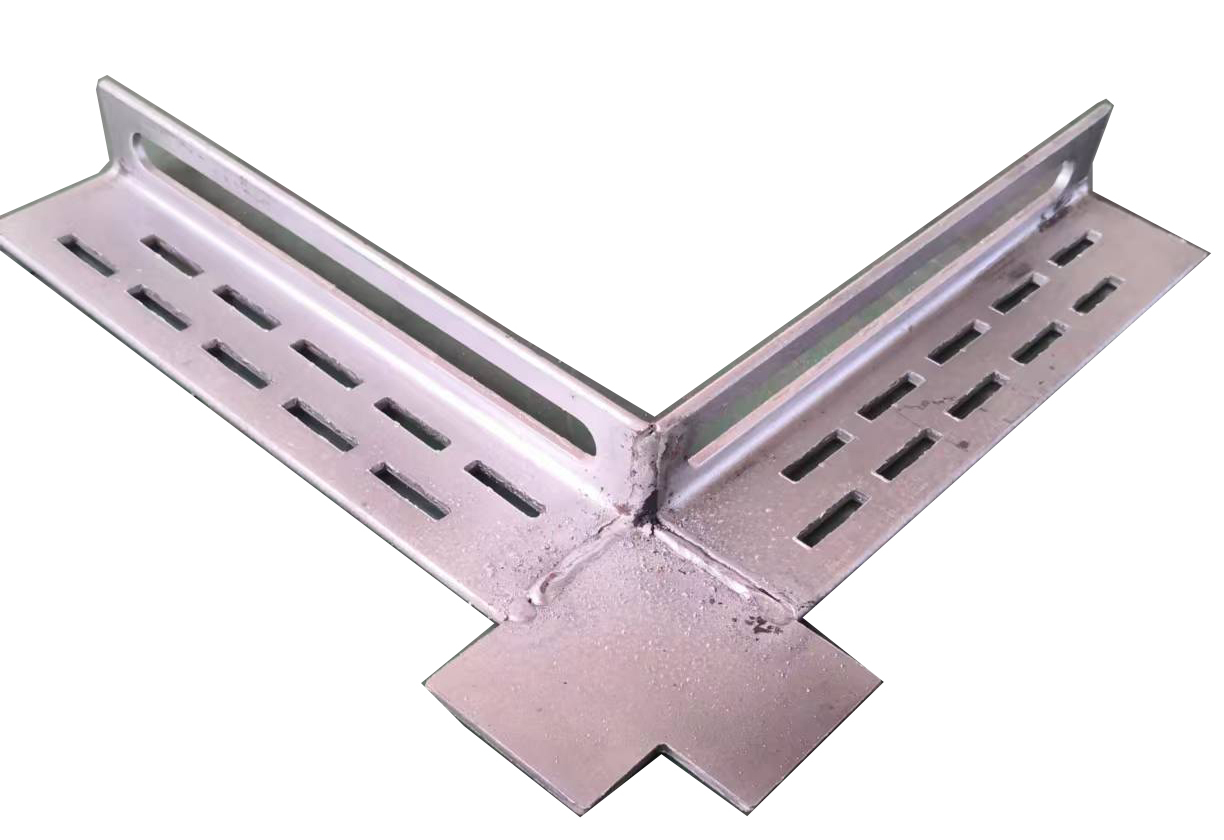

Q: How are Metal Angle Profiles utilized in construction projects?

A: Metal Angle Profiles, with their L-shaped cross-section, are used for bracing, framing, and reinforcing structures. They provide stability in corners, joints, and edges in both load-bearing and decorative applications. Their versatility makes them essential in steel frameworks and machinery.

Q: What factors should be considered when selecting a C-Section Metal profile?

A: Key factors include load requirements, span length, and environmental conditions like corrosion risk. C-Section Metal’s "C" shape offers excellent strength for columns, beams, and lightweight frames. Material thickness and compatibility with other components should also be evaluated.

Q: Can C-Section Metal and Metal I-Joists be used together in a single project?

A: Yes, C-Section Metal is often used for secondary framing or supports, while Metal I-Joists handle primary load-bearing spans. Their combined use optimizes structural efficiency and cost-effectiveness. Proper engineering ensures compatibility and adherence to safety standards.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025