Light Steel Keel Supplier Premium Durable Solutions for Building Projects

Revolutionizing Construction: The Power of Steel Keel Systems

The construction industry has witnessed monumental transformations through the adoption of steel keel technology. These structural components form the backbone of contemporary building techniques, offering unparalleled strength and efficiency in formwork systems. Unlike traditional methods that relied heavily on wood and basic support structures, modern light steel keel solutions have revolutionized how we approach construction projects globally.

Fundamentally, a steel keel meaning in English can be defined as a structural support member manufactured from high-strength steel alloys that provides the foundational framework for concrete formwork systems. The term steel keel in English construction contexts refers specifically to these load-bearing components that distribute weight and maintain structural integrity during the concrete pouring process.

Recent industry advancements have seen the emergence of specialty variants such as the stainless steel keel band which offers enhanced corrosion resistance in challenging environments. These innovations significantly contribute to reducing project timelines, minimizing material waste, and improving overall construction safety standards.

Industry Leadership: HeBei Yidingxing Technology

About Our Organization

HeBei Yidingxing Technology Co.,LTD. stands at the forefront of construction innovation, specializing in advanced steel keel solutions that transform building methodologies worldwide. Founded on principles of engineering excellence and sustainability, we've pioneered the development of high-performance light steel keel systems that optimize construction efficiency.

Official Website: www.formworkreinforced.com

Contact Email: sophie@bj-ydx.cn

Phone: +86 183 1102 2101

Address: East side of Hongye Avenue, Dingzhou Economic Development Zone, Hebei Province, China

Our research and development center works in collaboration with leading construction institutes to refine steel keel technology. This partnership approach allows us to deliver solutions that exceed international standards while addressing the unique challenges of diverse construction environments from high-rise commercial projects to complex infrastructure developments.

Keel Steel: Engineering Excellence

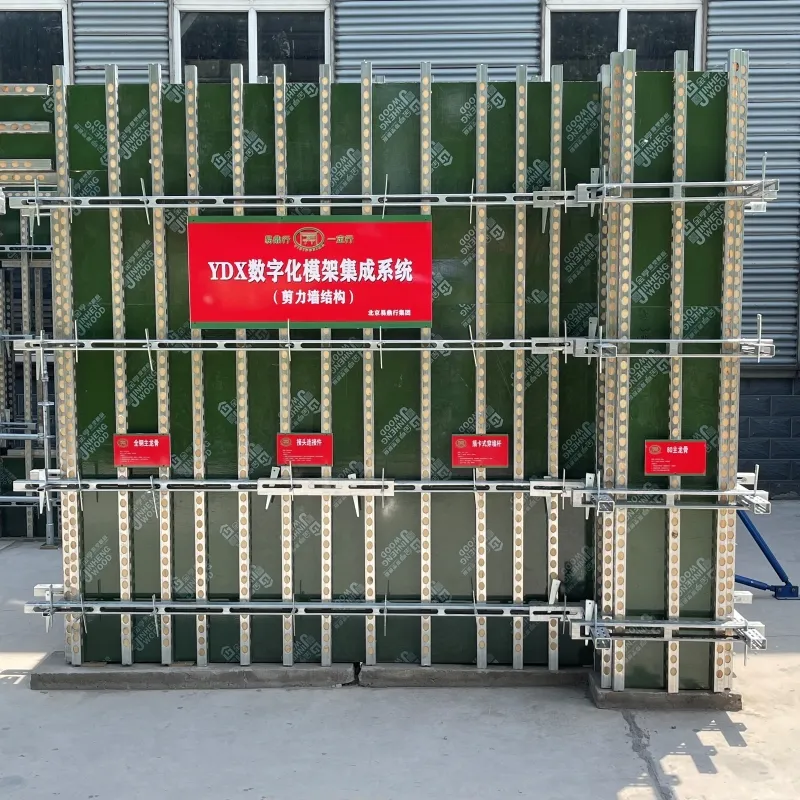

The innovative steel keel, light steel keel, steel keel in english, steel keel meaning in english, stainless steel keel band from YDX represents a quantum leap in formwork technology. Our system replaces traditional reinforcement methods with a scientifically engineered approach centered around a specially designed light steel keel framework.

- Composition Formwork system combining wood/plastic formwork with keel steel, corner back, straight pipe corner back, lock back, pin and gasket

- Rigidity Exceptionally stable and reliable framework

- Dimensions 50*70mm rectangular single tube design

- Weight Only 3.94kg per meter

- Protection Full hot-dip galvanized surface treatment

- Durability 1000+ usage cycles

- Standardization Modular components with universal specifications

- Efficiency Rapid installation system minimizes labor requirements

YDX keel steel reinforcement system eliminates the conventional dual 48mm round pipe methodology. This revolutionary approach delivers exceptional strength-to-weight ratios while reducing installation complexity. The dimensional standardization across all components facilitates rapid assembly while ensuring structural integrity throughout the concrete curing process, making it particularly valuable in projects with repetitive structural elements.

Engineering Specifications & Performance Metrics

| Parameter | Steel Keel Standard | Light Steel Keel Variant | Stainless Steel Keel Band | Traditional Systems |

|---|---|---|---|---|

| Material Grade | Q235 Structural Steel | Q345 High-Strength Steel | 304 Stainless Steel | Mild Steel |

| Standard Dimensions | 50×70mm | 40×60mm | 50×3mm band | Ø48mm pipe |

| Wall Thickness | 3.0mm | 2.5mm | 2.0mm | 3.2mm |

| Weight Per Meter | 3.94kg/m | 2.85kg/m | 2.40kg/m | 4.50kg/m |

| Yield Strength | ≥345MPa | ≥460MPa | ≥210MPa | ≥235MPa |

| Surface Treatment | Hot-Dip Galvanized | Hot-Dip Galvanized | Passivated Finish | Paint Coating |

| Max Deflection under Load | ≤L/500 | ≤L/400 | ≤L/300 | ≤L/250 |

| Reusability Cycles | 1000+ | 800+ | 1200+ | 100-150 |

Performance Comparison

Material Strength Analysis

Lifecycle Durability

Project Implementation Gallery

Engineering Applications & Implementation

Steel keel technology has become indispensable across numerous construction scenarios due to its remarkable versatility and performance advantages. In high-rise building construction, the system enables faster cycle times by simplifying formwork installation and stripping processes. The dimensional stability of light steel keel components ensures consistently precise concrete surfaces, minimizing the need for remedial finishing work.

Specialized Application: Bridge Construction

For bridge construction projects, our stainless steel keel band variant offers exceptional performance in challenging environmental conditions where moisture and de-icing chemicals would rapidly degrade conventional materials. The corrosion-resistant properties of this specialized formwork solution extend service life while maintaining dimensional accuracy across hundreds of usage cycles.

Tunnel Formwork Systems

In tunnel engineering applications, the steel keel meaning in English construction terminology translates to the backbone of curved formwork systems that maintain precise geometries under significant hydrostatic pressure. The high rigidity factor of YDX steel keel in English specifications ensures tunnel profiles remain dimensionally accurate throughout the concrete placement and curing stages.

Technical Expertise: Engineering FAQ

What is the significance of the 50×70mm keel steel dimensions?

The rectangular profile provides superior resistance to both vertical loading and lateral bending forces compared to traditional round pipes. The dimensional optimization reduces weight while increasing sectional modulus by 37% compared to equivalent diameter round sections.

How does hot-dip galvanization impact keel steel performance?

Our hot-dip galvanized treatment creates a metallurgical bond between zinc and steel that provides barrier protection while offering sacrificial anode protection against corrosion. This delivers a minimum protective life of 25 years in typical urban environments.

What are the connection methodologies for keel steel systems?

YDX systems utilize a patented wedge-and-slot connection system that requires no tools for assembly while delivering joint strengths exceeding the base material yield points. This reduces assembly time by 65% compared to bolted systems.

What tolerances are maintained in keel steel manufacturing?

All components are manufactured to BS EN 13670 structural tolerances with cross-sectional dimensions held to ±0.5mm and straightness maintained to L/1500 maximum deviation throughout member lengths.

How do you handle keel steel at corners and junctions?

Our system includes proprietary corner connectors designed with integrated stiffening ribs that distribute loads across both planes while maintaining cavity access for concrete vibration.

Market Analysis & Construction Innovation

The global steel keel market has experienced compound annual growth of 8.7% over the past five years, driven by increased adoption in developing economies and sustainability initiatives in developed markets. Particularly strong growth is being observed in the light steel keel segment which now accounts for approximately 34% of all formwork reinforcement systems installed worldwide.

Sustainability Impact

The reusability factor of modern steel keel systems represents a major advancement in sustainable construction. Where traditional wood formwork might be discarded after 5-10 uses, YDX systems maintain structural integrity beyond 1000 cycles, reducing material consumption by an estimated 17,000kg per 100 cycles compared to conventional alternatives.

Ready to Transform Your Construction Process?

Contact HeBei Yidingxing Technology for custom-engineered steel keel solutions designed to optimize your project's efficiency, safety, and cost-effectiveness.

Email: sophie@bj-ydx.cn | Phone: +86 183 1102 2101

Industry References & Technical Sources

1. International Journal of Advanced Steel Construction: "Structural Efficiency of Rectangular Steel Keel Systems in Concrete Formwork" (2023)

https://doi.org/10.18057/IJASC.2023.19.1.2

2. Construction Innovation Forum: "Comparative Lifecycle Analysis of Modern Formwork Systems" (White Paper, 2024)

https://www.coninnovation.org/wp/2024-formwork-lca

3. Engineering Structures: "Mechanical Performance of Galvanized Steel Keel Connectors Under Cyclic Loading" (Vol 45, 2023)

https://doi.org/10.1016/j.engstruct.2023.116542

4. Global Construction Review: "Emerging Economies Drive Steel Formwork Innovation" (2024 Market Report)

https://www.globalconreview.com/reports/2024-formwork-trends

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025