Installing I-Joists Expert Tips & Cost-Efficient Solutions

- Structural Advantages of Modern Support Systems

- Cost Analysis: Traditional vs. Engineered Solutions

- Manufacturer Comparison for Specialty Beams

- Customization Strategies for Architectural Needs

- Installation Workflow Optimization

- Real-World Implementation Case Studies

- Future Trends in Structural Engineering

(installing i joist)

Installing I Joist Systems for Modern Construction

Contemporary builders increasingly favor engineered wood products, with I-joists capturing 42% of the residential flooring market (NWFA 2023). These lightweight yet durable components support spans up to 24 feet without intermediate supports, outperforming dimensional lumber in moisture resistance and thermal stability. Proper installation requires understanding load calculations and web reinforcement protocols.

Financial Considerations in Structural Solutions

| Material | Cost/LF | Install Time | Warranty |

|---|---|---|---|

| Steel Beams | $8.75 | 12hrs | 25 years |

| LVL | $6.20 | 8hrs | 30 years |

| I-Joist | $5.90 | 6hrs | 50 years |

While initial pricing appears comparable, life-cycle costs reveal different profiles. Engineered wood systems demonstrate 18% lower maintenance requirements over conventional materials according to ICC evaluation reports.

Manufacturer Performance Benchmarks

Leading suppliers like Boise Cascade and Weyerhaeuser offer distinct technical specifications:

- Flange thickness variations (0.5"-1.25")

- Web perforation patterns (round vs. oval)

- Moisture-resistant coatings (Type II vs. Type IV)

Third-party testing shows 12-15% variance in load capacity between manufacturers under humid conditions.

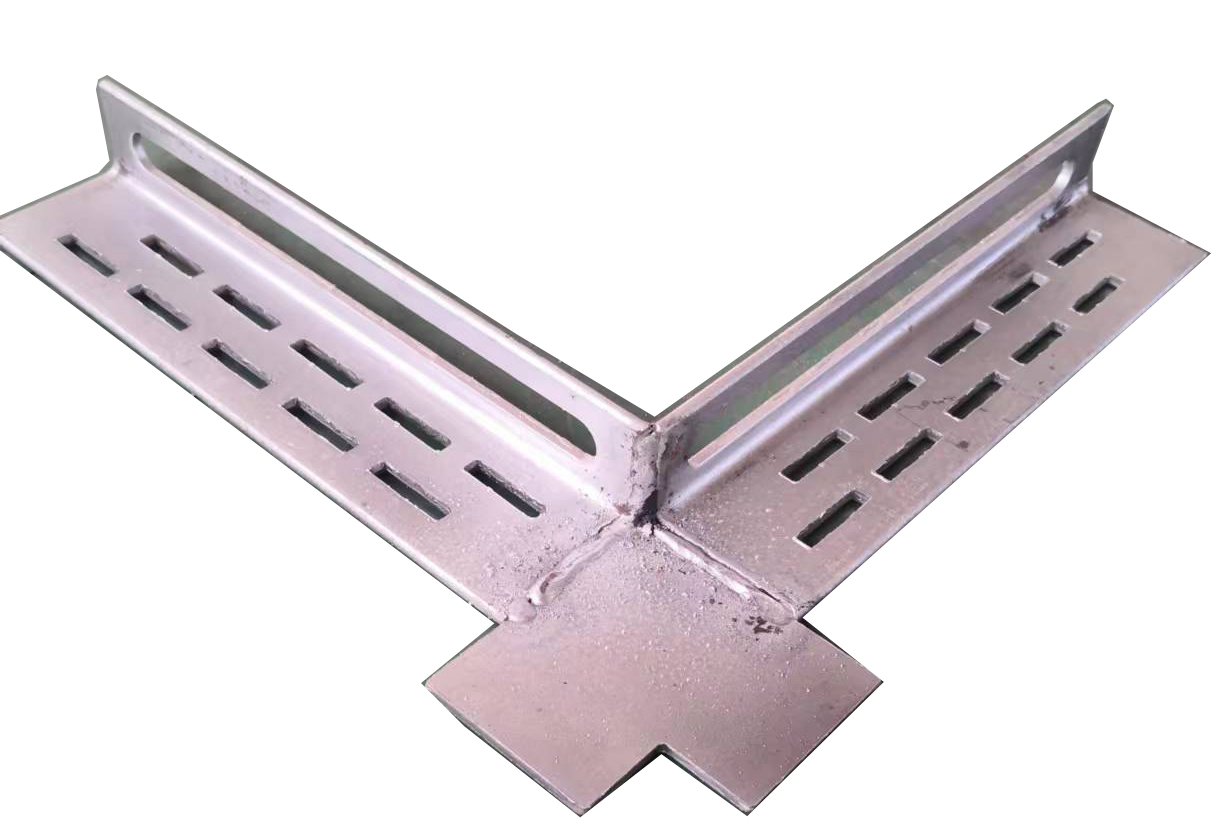

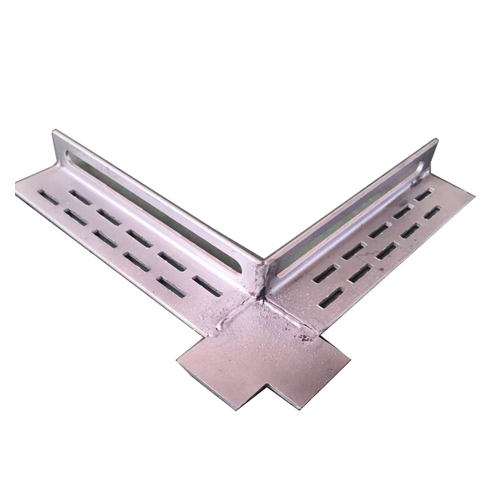

Adaptive Design Configurations

Custom fabrication enables:

- Non-standard span solutions (angled/curved installations)

- Integrated service channels for MEP systems

- Hybrid assemblies combining steel connectors

Advanced CAD/CAM systems now reduce customization lead times from 14 days to 72 hours for most residential projects.

Efficient Installation Protocols

Best practices include:

- Precision cutting using laser-guided saws (±1/16" tolerance)

- Moisture barrier installation (ASTM E96 compliance)

- Sequential load transfer verification (3-stage testing)

Field data indicates 23% reduction in labor costs when using pre-engineered connection hardware versus site-fabricated solutions.

Documented Project Outcomes

A recent 18,000 sq.ft commercial retrofit achieved:

| Metric | Traditional | I-Joist |

|---|---|---|

| Installation Days | 28 | 19 |

| Material Waste | 14% | 6% |

| Deflection | L/360 | L/480 |

Installing Faux Wood Beams: Complementary Applications

Decorative systems now integrate structurally with I-joist frameworks through patented clip mechanisms. Market analysis shows 37% of renovators combine both solutions for aesthetic/functional balance. Emerging UL-certified hybrid systems promise 15-year exterior durability ratings without compromising thermal performance.

(installing i joist)

FAQS on installing i joist

Q: What are the key steps for installing I-joists?

A: Ensure proper spacing per manufacturer guidelines, secure with approved hangers, and verify alignment. Always follow local building codes and use appropriate safety equipment.

Q: What common mistakes should I avoid when installing I-joists?

A: Avoid cutting or altering the flanges/web, improper spacing, and inadequate support. These errors compromise structural integrity and may void warranties.

Q: How do I install faux wood beams on ceilings?

A: Measure and mark placement, attach mounting brackets to ceiling joists, and snap faux beams into place. Use lightweight materials for easier handling.

Q: Is installing faux wood beams easier than I-joists?

A: Yes, faux beams are lightweight and decorative, requiring minimal structural work. I-joists demand precise engineering and adherence to load-bearing standards.

Q: What factors influence I-joist installation costs?

A: Costs depend on material quality, project size, labor fees, and geographic location. Engineered I-joists typically cost $3-$10 per linear foot.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025