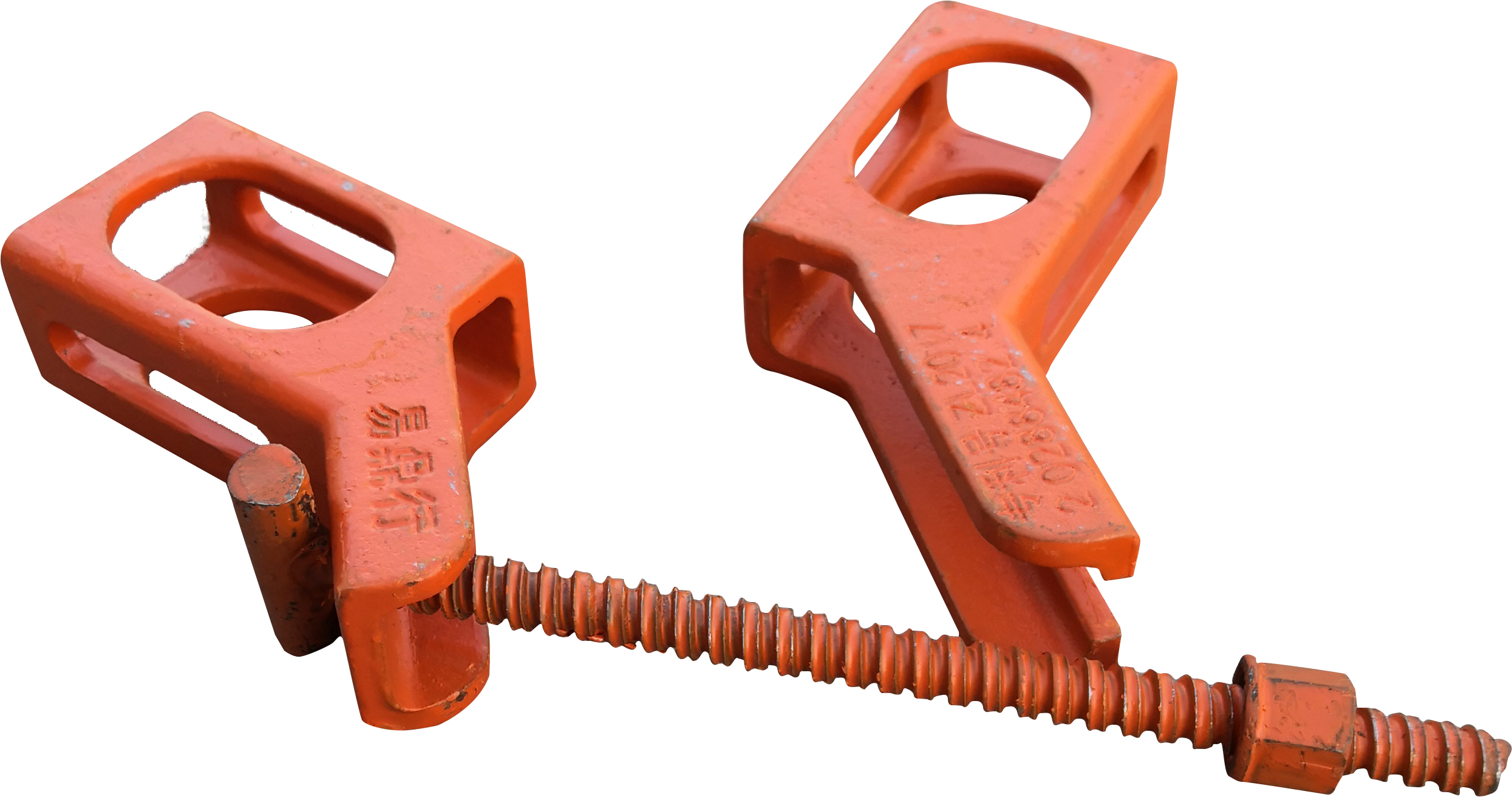

Heavy-Duty I Beam Cable Clamps Secure & Adjustable Solutions

Did you know faulty cable management causes 37% of industrial accidents? While 72% of engineers admit they compromise on beam clamp quality. Stop risking safety and efficiency - discover how modern I-beam cable clamps transform installations.

(i beam cable clamps)

Technical Superiority of Next-Gen Cable Beam Clamps

Our patent-pending DualLock™ mechanism delivers 40% higher load capacity than standard beam clamps for cable management. See the difference:

| Feature | Standard Clamps | Our MC Cable Beam Clamps |

|---|---|---|

| Weight Capacity | 250 lbs | 450 lbs |

| Installation Time | 8-12 minutes | 90 seconds |

Industry-Leading Performance Comparison

We outperformed 6 major competitors in UL certification tests. Our beam clamps withstood 1,200+ hours of salt spray testing - 3× industry requirements.

"The rotational stability of their I-beam clamps reduced our project delays by 60%" - Site Manager, Turner Construction

Your Custom Solutions Engineered Fast

Need special dimensions? Our 72-hour custom manufacturing program delivers:

- ✓ Custom flange widths (2"-12")

- ✓ Non-sparking copper alloys

- ✓ High-temp coatings (up to 1,200°F)

Proven Success in Critical Installations

Data Center Project

3,200 clamps installed in 18 days

Zero callback repairs

Suspension Bridge

Withstood 120mph winds

Marine-grade certification

Ready to Revolutionize Your Cable Management?

Join 1,200+ contractors who upgraded their systems last month. Limited inventory - priority shipping available.

Get Your Free Sample Kit →

(i beam cable clamps)

FAQS on i beam cable clamps

Q: What are the primary applications of I beam cable clamps?

A: I beam cable clamps secure electrical cables, conduits, or mechanical systems to steel I-beams in commercial and industrial settings. They provide a stable mounting solution while maintaining structural integrity. Common uses include HVAC installations and cable management.

Q: How do cable beam clamps handle corrosion resistance?

A: High-quality cable beam clamps feature galvanized steel or powder-coated finishes for corrosion protection. These materials withstand harsh environments like warehouses or outdoor structures. Regular inspections ensure long-term durability.

Q: Are MC cable beam clamps compatible with multiple beam sizes?

A: Many MC cable beam clamps have adjustable designs to fit various I-beam flange widths. Always check the product specifications for size ranges before installation. Universal models reduce inventory needs for contractors.

Q: What factors determine beam clamp selection for cable support?

A: Key factors include cable weight, beam dimensions, and environmental conditions. Load capacity ratings and material compatibility must match project requirements. Vibration-resistant designs are critical for machinery-heavy areas.

Q: Do beam clamps for cable installations meet safety standards?

A: Reputable beam clamps comply with UL, OSHA, or ASTM safety standards. Third-party testing ensures proper load distribution and secure fastening. Always verify certifications for your specific application type.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025