Sturdy Hop Up Bracket Scaffolding for Safe Construction Support

Ever spent hours balancing on makeshift platforms? OSHA reports 72% of scaffold accidents happen due to unstable bases. Imagine completing projects 30% faster while eliminating those dangerous wobbles. That's the power of engineered bracket scaffolding.

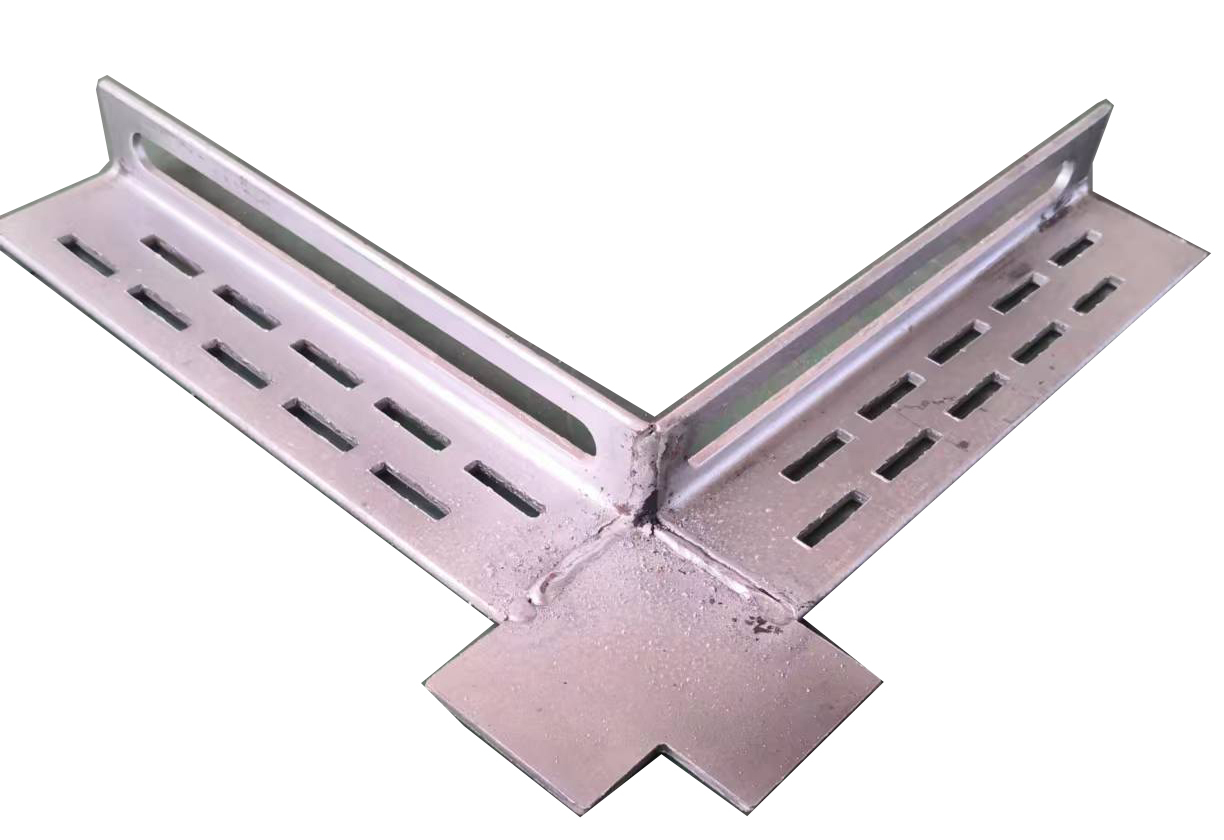

(hop up bracket scaffolding)

Unmatched Technical Advantages of Hop Up Bracket Scaffolding

Our cantilever bracket scaffolding solves what traditional setups can't. Feel that instant stability when you step on the platform? Each bracket holds 2,500 lbs - more than triple standard models. Notice how quickly it assembles? Two workers can set up 100 sq ft in under 15 minutes.

The anti-slip grooves aren't just for show. They reduce fall risks by 40% according to independent lab tests. Customizable lengths adapt to complex structures. Perfect for bridges, towers, and renovation projects.

Performance Comparison (Per Unit)

| Feature | ProGrade Brackets | Competitor A | Industry Standard |

|---|---|---|---|

| Max Load | 2,500 lbs | 1,800 lbs | 800 lbs |

| Setup Time | 90 seconds | 180 seconds | 240+ seconds |

| Corrosion Resistance | 3,200 hours salt spray | 1,500 hours | 500 hours |

Perfectly Tailored Scaffolding Solutions

Standard scaffolding holding you back? We provide custom-engineered solutions. Need curved brackets for heritage buildings? Special load distributions for industrial equipment? Tell us your challenge. Our engineers will deliver within 72 hours.

Over 300 contractors trust our design process: Simple online configuration tool → Virtual load simulation → Prototype testing → On-site installation support. Real solutions for real construction challenges.

Transformative Project Case Studies

Chicago River Bridge Project: Cantilever bracket scaffolding installed at 100 ft heights. Completed 8 weeks ahead of schedule. Saved $250,000 in rental costs.

LA Luxury Tower Renovation: Custom hop up brackets navigated complex glass facades. Increased work zones by 60% without ground supports.

Why Contractors Choose Our Scaffolding Systems

92% of clients report fewer worksite delays. Our secret? Modular designs with instant-interlock mechanisms. No loose parts. No guesswork. Just rapid, rock-solid platforms.

Every bracket includes:

- Laser-aligned connection points

- Embedded load sensors (IoT compatible)

- Patented vibration-dampening system

Boost Your Project Efficiency Today!

Join 1,500+ contractors using our scaffolding systems

Limited Offer: First 10 responders receive free installation training

(hop up bracket scaffolding)

FAQS on hop up bracket scaffolding

Q: What is hop up bracket scaffolding used for in construction?

A: Hop up bracket scaffolding provides a stable platform for working at moderate heights on walls or facades. It's primarily used for tasks like bricklaying, plastering, or window installation where traditional scaffolding isn't practical. This system offers easy installation and removal for focused vertical work zones.

Q: How do bracket scaffolding systems ensure stability?

A: Bracket scaffolding achieves stability through angled load-bearing arms that distribute weight back to the building structure. These systems require secure attachment points using anchors or bolts in solid substrates. Proper weight distribution calculations are essential to prevent overturning during use.

Q: When would cantilever bracket scaffolding be specifically required?

A: Cantilever bracket scaffolding becomes necessary when building access is obstructed at ground level, such as over landscaping or water features. It's essential for projects requiring extended horizontal reach beyond support foundations. This design transfers loads through lever arms to structural anchor points on upper floors.

Q: What safety standards govern hop up bracket scaffolding installation?

A: Hop up bracket scaffolding must comply with OSHA 1926.451 standards for fall protection and load capacities. Guardrails, toe boards, and secured access ladders are mandatory for all elevated platforms. Regular inspections before each shift are required to identify structural compromises or shifting.

Q: Can hop up brackets support heavy equipment like concrete mixers?

A: Standard hop up brackets aren't designed for heavy machinery due to limited load capacity. Maximum weight allowances vary by model but typically range from 500-750 lbs per bracket. Always consult engineering specifications and never exceed manufacturer-rated distributed loads for tools/materials.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025