High Rise Building Formwork Systems Durable & Efficient Solutions

- Introduction to Modern High-Rise Construction Challenges

- Technical Superiority of Advanced Formwork Systems

- Head-to-Head: Leading Formwork Manufacturers Compared

- Custom Engineering Solutions for Unique Projects

- Case Studies: Global Skyscraper Success Stories

- Safety Standards in Vertical Construction

- Future Trends in High-Rise Formwork Technology

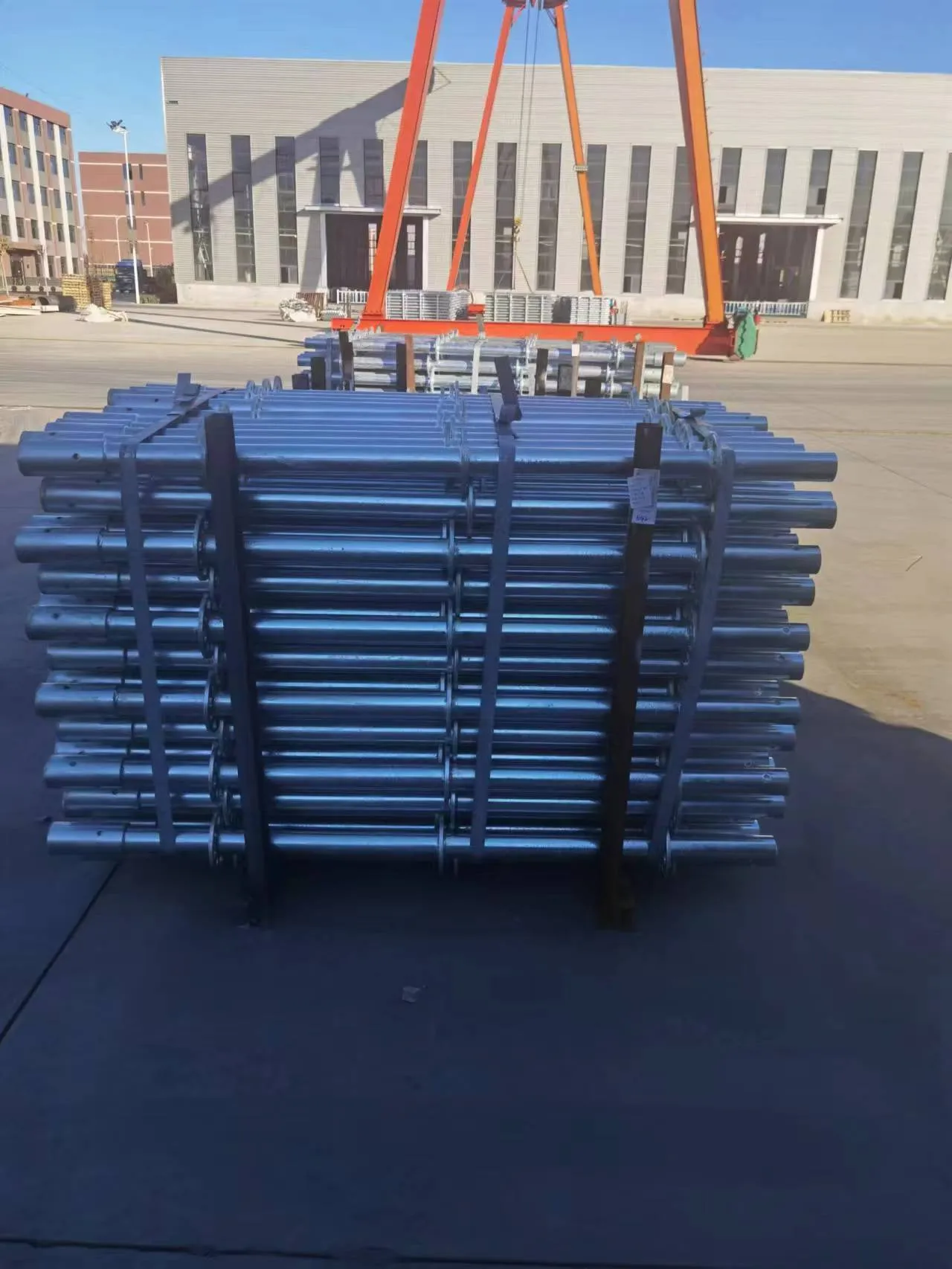

(high rise building formwork)

Addressing Modern High-Rise Building Formwork Challenges

Urbanization drives 72% annual growth in skyscraper construction, creating unprecedented demands for high-rise building formwork systems. Structural complexity, wind resistance (up to 150 mph requirements), and rapid project timelines necessitate...

Technical Superiority of Advanced Formwork Systems

Third-generation aluminum formworks achieve 40% weight reduction compared to steel alternatives while maintaining 25 kN/m² load capacity. Key innovations include:

- Modular panel connections with ±2mm precision

- Hydraulic auto-climbing mechanisms (3m/min ascent)

- Embedded IoT sensors monitoring concrete curing

Head-to-Head: Leading Manufacturers Compared

| Brand | Material | Max Height | Cycle Time | Cost/m² |

|---|---|---|---|---|

| PERI Skydeck | Aluminum Composite | 650m | 5 days/floor | $185 |

| Doka Xpress | Carbon Steel | 550m | 6.5 days/floor | $210 |

Custom Engineering Solutions for Unique Projects

Shanghai Tower's twisted form required 1,200 bespoke formwork panels with 37 unique angles. Customization parameters include:

- Curvature tolerance: 0.5° precision

- Surface finish options (Class A1 to C3)

- Integrated service conduits

Case Studies: Global Skyscraper Success Stories

Merdeka PNB118 (Kuala Lumpur):

- Height: 644m

- Formwork system: Hybrid climbing-shuttering

- Result: 22% faster cycle vs conventional methods

Safety Standards in Vertical Construction

OSHA-compliant systems reduce fall risks by 89% through:

- Anti-slip platforms (≥μ0.6 friction coefficient)

- Modular guardrails with 250kg impact resistance

Advancing High-Rise Building Formwork Technology

Robotic formwork assembly lines now achieve 95% component accuracy, while graphene-enhanced composites promise 60% weight reduction in 2025 prototypes. The $42.7B global formwork market increasingly prioritizes...

(high rise building formwork)

FAQS on high rise building formwork

Q: What materials are best for high rise building formwork?

A: Aluminum and steel are ideal for high rise formwork due to their strength and reusability. Plywood is often used for sheathing to create smooth concrete surfaces. These materials ensure durability under heavy loads and repetitive use.

Q: How does formwork for high rise buildings differ from low-rise structures?

A: High-rise formwork requires higher load-bearing capacity and modular systems for faster assembly. It often integrates climbing or slipform systems to accommodate vertical progression. Safety features like advanced bracing are prioritized for extreme heights.

Q: What safety standards apply to scaffolding systems in high rise construction?

A: Scaffolding must comply with OSHA/EN standards for fall protection and load capacity. Regular inspections of guardrails, platforms, and tie-offs are mandatory. Wind resistance and seismic factors are critical in design for tall structures.

Q: Can the same formwork system be reused across multiple high rise projects?

A: Yes, modular systems like aluminum formwork are designed for 200+ reuse cycles. Proper maintenance and compatibility with floor plans ensure cost-effectiveness. Adjustable components allow adaptation to varying building designs.

Q: How do climbing formwork systems improve high rise construction efficiency?

A: Climbing formwork uses hydraulic jacks to self-lift with each completed floor, reducing crane dependency. It enables continuous vertical casting cycles, accelerating project timelines. This system minimizes labor and material handling at extreme heights.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025