High-Quality Steel Keel Solutions for Construction & Design Needs

As the foundation of modern construction support systems, steel keel and its derivatives such as light steel keel and stainless steel keel band play a vital role in architectural engineering. HeBei Yidingxing Technology Co.,LTD. (Official Site) stands at the forefront of innovation, production, and technical progress in this industry.

Website: https://www.formworkreinforced.com

Email: sophie@bj-ydx.cn

Phone: +8618311022101

Address: East side of Hongye Avenue, Dingzhou Economic Development Zone, Hebei Province

1. Industry Overview & Trends of Steel Keel

The steel keel industry has undergone tremendous changes over the past decade, driven by urbanization, advanced construction needs, and emphasis on sustainable building practices. Especially, light steel keel is now a preferred choice for frameworks due to weight reduction, high strength, standardization, and excellent reusability. According to the Journal of Building Engineering, the trend is to adopt modular, recyclable systems for speed, safety, and lower total cost of ownership.

In international markets, "steel keel" in English represents a structural spine that supports walls, ceilings, and formwork. The steel keel meaning in English specifically denotes a straight or profile section forming the core load-bearing part of a non-loadbearing partition or ceiling.

Stainless steel variants, such as stainless steel keel band, are popular in environments requiring corrosion resistance and long-term serviceability.

2. About Keel Steel from HeBei Yidingxing Technology Co.,LTD.

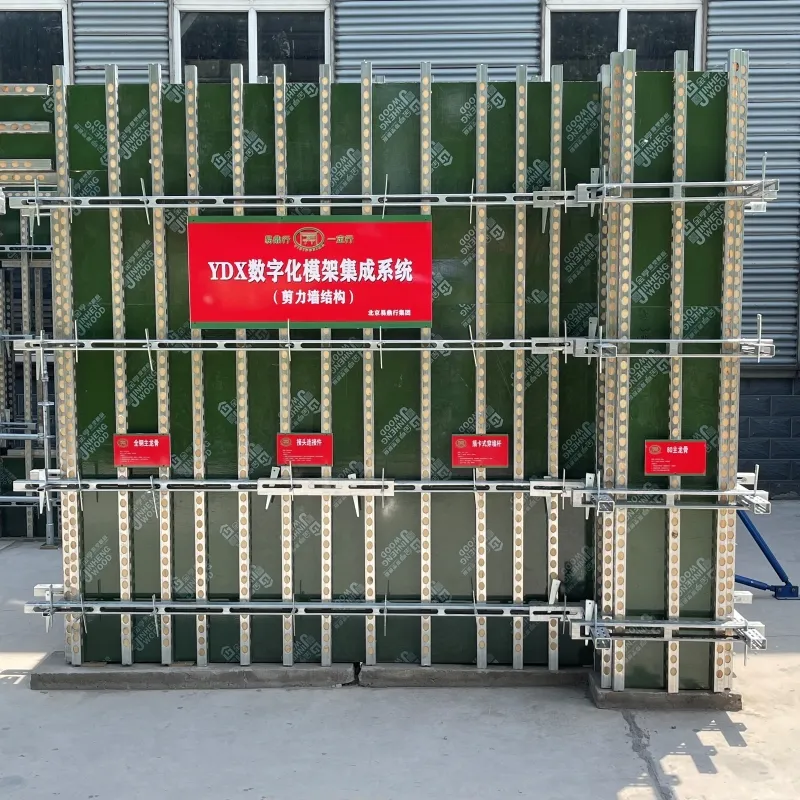

The Keel Steel system pioneered by HeBei Yidingxing Technology Co.,LTD. integrates advanced formwork engineering, using a combination of wood or plastic formwork with steel keel and dedicated accessories. The design features:

- Rigid, stable, modular, and reliable system configuration

- Light weight (3.94 kg/m), compact size, easy handling, and hassle-free transportation

- Highly standardized and modularized components

- Uniform specifications, rapid installation, and strong versatility for diverse wall/shearwall lengths

- Galvanized finish for maximum anti-corrosion & up to 1000 turnovers for environmental sustainability

- No need for connection; can fully substitute traditional double-48 pipe support

- High recycling value

The YDX steel keel specifications adopt a rectangular single tube design (50×70mm, wall thickness 3.0mm), streamlining construction and enhancing safety.

3. Technical Parameters of Steel Keel: Comparative Table

| Parameter | YDX Keel Steel | Light Steel Keel | Stainless Steel Keel Band | Traditional Pipe System |

|---|---|---|---|---|

| Section Size | 50×70mm | 38×12mm / 50×20mm | Customized | Φ48mm pipe |

| Wall Thickness | 3.0mm | 0.6–1.2mm | 1.0–2.0mm | 3.5mm |

| Material | Q235 Galvanized | Q195/Q235 Galvanized | 304/316 Stainless Steel | Q235/Q345 Carbon Steel |

| Unit Weight (kg/m) | 3.94 | 1.0–1.6 | 2.5–3.5 | 5.3 |

| Max Turnover Times | 1000+ | 60–120 | 500+ | 180 |

| Surface Finish | Hot-dip Galvanized | Zinc Coat/Galvanized | Polished/Brushed | Painted/Rusted |

| Applications | Formwork, Shear Wall, Slab Support | Ceiling, Partition, Light Walls | Wet, Marine & Clean Room | Formwork, Temporary Support |

4. Data Visualization: Steel Keel Trends & Technical Indexes

5. Application Scenarios: Where Steel Keel Excels

- Shear Wall Formwork: Particularly for high-rise buildings, YDX steel keel replaces traditional pipe supports for improved uniformity and structural safety.

- Slab Supports: Used for concrete flooring and flat roof support, offering fast installation and easy demounting.

- Ceiling Frameworks: Light steel keel is favored for commercial ceilings and partitioning due to its lightness and speed.

- Marine Structures: Stainless steel keel band is applied where wet or corrosive environments demand high corrosion resistance.

- Modular Building Solutions: When modularity and multiple turnovers are needed, such as prefab housing or rapid infrastructure deployment.

- Special Cleanroom or Hospital Environments: Stainless, hot-dip galvanized, or powder-coated options to meet hygiene and non-contamination regulations.

Learn more about the product here: YDX Keel Steel

6. Innovation & Sustainability: Environmental Impact of Modern Steel Keel Solutions

Modern construction puts a significant focus on the environmental lifecycle of the steel keel. With up to 1000 turnovers per piece, the recycling and reuse rates have surged. This not only cuts long-term costs for contractors but also sharply reduces waste compared to traditional wooden or carbon steel systems. Powder coating and hot-dip galvanizing also ensure minimal long-term maintenance, vital for sustainability certifications like LEED or BREEAM.

The modularity and standardized production methods of Keel Steel mean drastically lower errors, less onsite waste, and easier logistics.

7. Technical FAQ: Key Professional Terms & Standards for Steel Keel

8. Why Choose HeBei Yidingxing Technology Co.,LTD. for Your Steel Keel Solution?

- Advanced R&D: Decades of technology accumulation and innovation, focused on durability, modularity, and cost-efficiency.

- Strict Quality Management: Full ISO 9001:2015 compliance; every batch is tested for strength, zinc thickness, and elongation.

- Project Support: Design consulting, on-site training, and after-sales technical support for all steel keel customers.

- Global Export Experience: Projects in Europe, SEA, Africa, and the Americas – with complete supporting documentation.

- Competitive Pricing: Direct-from-manufacturer pricing and consistent inventory.

For direct inquiries or technical consultation regarding steel keel, light steel keel, or stainless steel keel band, contact us:

Email: sophie@bj-ydx.cn | Phone: +8618311022101

9. Reference Links

- "Trend and Development Prospect of Lightweight Keel System"(Journal of Building Engineering)

- "Application and Innovation of Steel Keel in Modern Highrise Formwork" (Zhulong Construction Forum)

- "Engineering Properties of Galvanized Keel in Building Framework" (ResearchGate)

- Discover YDX Keel Steel: Product Details

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025