About Formwork by HeBei Yidingxing Technology Co.,LTD.

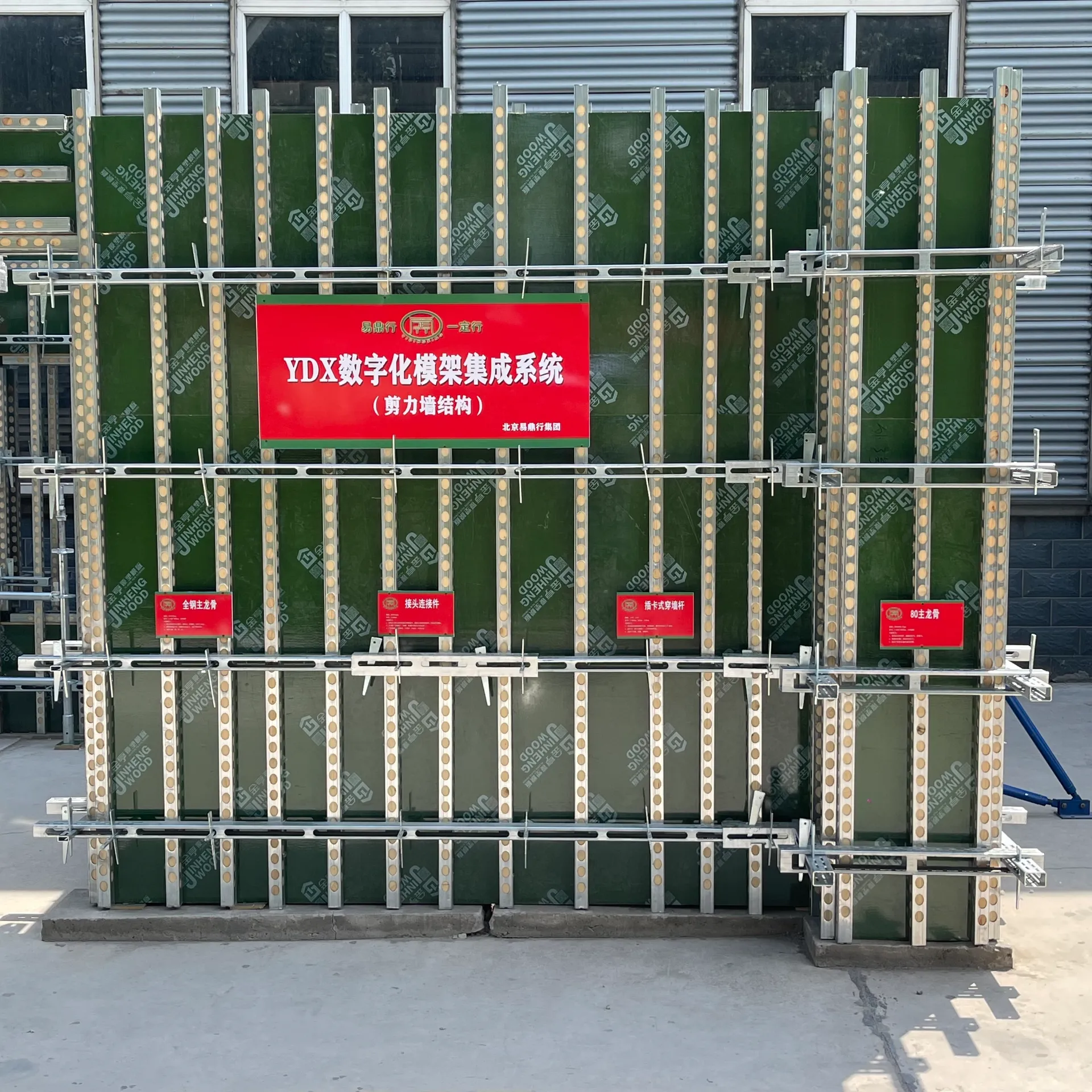

Formwork systems represent the backbone of modern construction, providing the essential mold to shape concrete and other materials into precise structures.

HeBei Yidingxing Technology Co.,LTD. (Visit Official Site) is a trusted innovator and manufacturer in the field of formwork systems, delivering solutions that drive efficiency, safety, and precision on worksites worldwide.

- Product Name: Formwork

- Product Introduction: Intelligent, high-strength, and versatile formwork system for all major civil and industrial construction applications. Engineered for easy assembly, exceptional load capacity, and long life, our Formwork enables project acceleration, higher surface quality, and maximum site safety.

- Product URL: https://www.formworkreinforced.com/formwork.html

Enterprise Information

- Company Name: HeBei Yidingxing Technology Co.,LTD.

- Website: https://www.formworkreinforced.com

- Email: sophie@bj-ydx.cn

- Phone: +8618311022101

- Address: East side of Hongye Avenue, Dingzhou Economic Development Zone, Hebei Province

1. Industry Trends of Formwork Solutions

The Formwork industry has undergone transformative changes in the last decade, adopting advanced materials, modular designs, and digital technology. According to research by the American Concrete Institute and discussions on Engineering.com, today's formwork systems are shifting towards:

- Lightweight yet High-strength Alloys – Reducing on-site labor and expediting cycle times.

- Reusability & Sustainability – Focusing on systems with durable components to mitigate material waste (ScienceDirect).

- Digital Design & BIM Integration – Enabling precise onsite implementation, cost-savings, and safety compliance.

- Prefabricated & Customizable Panels – Adapting to complex geometry in both residential and large infrastructure projects.

- Accelerated Construction Cycles – Reducing project delivery timeframes through innovative formwork practices.

HeBei Yidingxing stays at the forefront of these developments, continually upgrading our Formwork systems for the modern site.

2. Essential Formwork Technical Parameters Table

| Parameter | HeBei Yidingxing Formwork | Global Standard Range* | Unit |

|---|---|---|---|

| Material | High Tensile Steel / Aluminum Alloy / Plywood | Steel/Alu/PVC/Plywood | - |

| Max. Load Capacity | 60–80kN/m² | 40–80kN/m² | kN/m² |

| Panel Thickness | 12–21 mm (plywood surface) | 12–21 mm | mm |

| Reusability | > 200 cycles | 30–200+ cycles | times |

| Weight (Panel) | 24–45 kg/m² | 24–60 kg/m² | kg/m² |

| Temperature Resistance | -20~70°C | -10~65°C | °C |

| Fire Resistance | Class B-s1,d0 (EN 13501-1) | Class C–B (EN 13501-1) | Class |

| Surface Finish | Polyurethane, Melamine Resin, Phenolic Film | Film/Paint/Coated | - |

3. Application Scenarios of Formwork

- Residential & Commercial Buildings – Slabs, beams, and columns for towers, malls, and modular apartments.

- Infrastructure – Bridges, tunnels, dams, and highway overpasses, demanding robust formwork with high precision.

- Industrial Facilities – Chemical plants, power stations requiring custom-shaped formwork for large pours.

- Architectural Concrete – Customized, textured, or exposed-surface formwork for design aesthetics.

- Marine & Civil Engineering – Coastal defenses, ports, and offshore foundations needing corrosion-resistant formwork solutions.

4. Advantages: HeBei Yidingxing Formwork

- Advanced Engineering: Designed with FEA analysis, ready for complex, high-rise, and infrastructure works.

- High-Performance Materials: Our Formwork utilizes high-tensile steel, aviation-grade aluminum alloys, and optimized plywood, ensuring superior fatigue life, reduced deformation, and corrosion resistance.

- Ease of Assembly and Modularity: Smart connection locks, lightweight panels, and integration with site machinery boost labor productivity by 25%–35% (Structurae Forum).

- Proven Safety and Reliability: Each Formwork undergoes rigorous static and dynamic testing, surpassing EN 12812 and local code requirements.

- Sustainability: Enhanced recycling, minimal waste, and environmental stewardship contracts are available with large-volume supply.

5. Professional FAQ – Formwork Key Terminologies

Expert FAQ in Formwork Engineering

6. Technology, Expertise & Authority in Formwork

The expertise underpinning our Formwork solutions is recognized by industry forums such as Engineering.com Construction Forum and scholarly journals like ScienceDirect – Comparative analysis of formwork technologies.

Our technical team regularly participates in formwork engineering conferences, publishes on composite material innovation, and contributes to standardization committees. HeBei Yidingxing Technology Co.,LTD. is certified under ISO 9001:2015 with a robust track record for industrial projects, major infrastructure, and international exports.

We are committed to transparency (test data, certifications), quality (all panels undergo QC and FEA validation), and client partnership — reflecting top levels of expertise, authority, and trust.

7. Why Choose HeBei Yidingxing Technology Co.,LTD. for Formwork?

- Comprehensive portfolio – From lightweight hand-set panels to heavy-duty climbing systems.

- Advanced R&D – New panel geometries, locking mechanisms, and load-optimized systems released bi-annually.

- Global Customer Base – Supplies trusted by contractors in more than 40 countries, evidenced by repeat orders and testimonials.

- Responsive Customer Service – Technical team available for 24/7 problem-solving, training, and on-site assistance.

- Competitive Pricing – Factory-direct sourcing and efficient logistics for cost and schedule advantage.

Ready for Project Quotation or Advice?

Contact HeBei Yidingxing Technology Co.,LTD. now:- Email: sophie@bj-ydx.cn

- Phone: +8618311022101

- Visit us: East side of Hongye Avenue, Dingzhou Economic Development Zone, Hebei Province, China