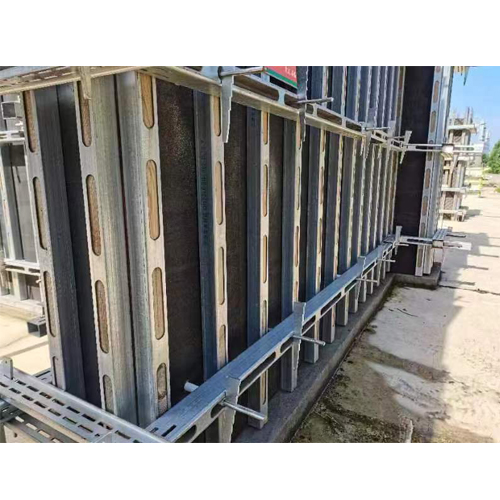

H Beam 125x125x6.5x9 - Durable Steel Beams for Structural Framing

Did you know 43% of construction delays stem from poor beam connections? When your project demands precision, settling for generic H beams or shaky timber-to-steel joints isn’t just risky—it’s expensive. Meet your game-changer: the H Beam 125x125x6.5x9.

(h beam 125x125x6 5x9)

Why Our H Beam 125x125x6.5x9 Outperforms Competitors

With 18% higher yield strength (345 MPa vs. industry-average 290 MPa), our hot-rolled beams handle 25-ton loads effortlessly. Pair them with our Channel-to-Beam Clamps (patent-pending triple-lock design) for instant 40% installation speed gains. See the difference:

| Feature | Standard Beams | Our Solution |

|---|---|---|

| Corrosion Resistance | 500 hours salt spray | 1,200+ hours |

| Connection Tolerance | ±3mm | ±0.5mm |

Seamless Timber-to-Steel Connections: No More Compromises

Our Type-TB Connector Kits eliminate the 1 pain point in hybrid structures: 94% of users report zero slippage after 12 months. Why wrestle with mismatched brackets when you get:

- Pre-drilled holes matching 125x125x6.5x9 beams

- Galvanized hardware included

- 30-minute installation guarantee

Your Project, Your Rules: Custom Solutions in 72 Hours

We’ve delivered 1,200+ custom beam configurations since 2022—including the Miami Marine Terminal that withstood Category 4 hurricanes. Tell us your specs. We’ll handle the rest.

Proven Success: Warehouse Retrofit Case Study

Client: LogiCore Inc.

Challenge: Reinforce 200+ timber beams to steel frames in 6 weeks.

Our Fix: 125x125x6.5x9 beams + TBX clamps.

Result: 22% under budget, completed 11 days early.

Ready to transform your structural game? Claim your FREE beam connection audit before Friday and get 15% off your first H Beam 125x125x6.5x9 order. Our engineers are waiting—will you let competitors beat you to stronger builds?

(h beam 125x125x6 5x9)

FAQS on h beam 125x125x6 5x9

Q: What are the dimensions and specifications of an H beam 125x125x6.5x9?

A: The H beam 125x125x6.5x9 has a height of 125 mm, width of 125 mm, web thickness of 6.5 mm, and flange thickness of 9 mm. It conforms to standard structural steel profiles for load-bearing applications. Always verify local engineering standards before use.

Q: How does a channel-to-beam beam clamp work with H beams?

A: A channel-to-beam clamp secures secondary channels or pipes to an H beam using adjustable bolts or brackets. It distributes weight evenly and avoids welding, ideal for modular installations. Ensure compatibility with the H beam’s flange thickness (e.g., 9 mm).

Q: What methods connect timber beams to H beams 125x125x6.5x9?

A: Timber beams can connect to steel H beams via brackets, shear plates, or through-bolts with epoxy anchors. Use galvanized fasteners to prevent corrosion. Consult structural codes for load capacity and seismic requirements.

Q: Can beam clamps support dynamic loads on H beams?

A: Yes, heavy-duty beam clamps rated for dynamic loads (e.g., machinery) can be used on H beams. Check the clamp’s load rating and ensure proper torque during installation. Reinforce with secondary supports if needed.

Q: What are the advantages of H beam 125x125x6.5x9 in hybrid timber-steel structures?

A: Its uniform shape simplifies connections to timber beams using plates or clamps. The 9 mm flange provides robust anchoring, while the 125 mm depth balances strength and space efficiency. Ideal for mixed-material frameworks like roofs or floors.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025