Jan . 31, 2025 01:03

Back to list

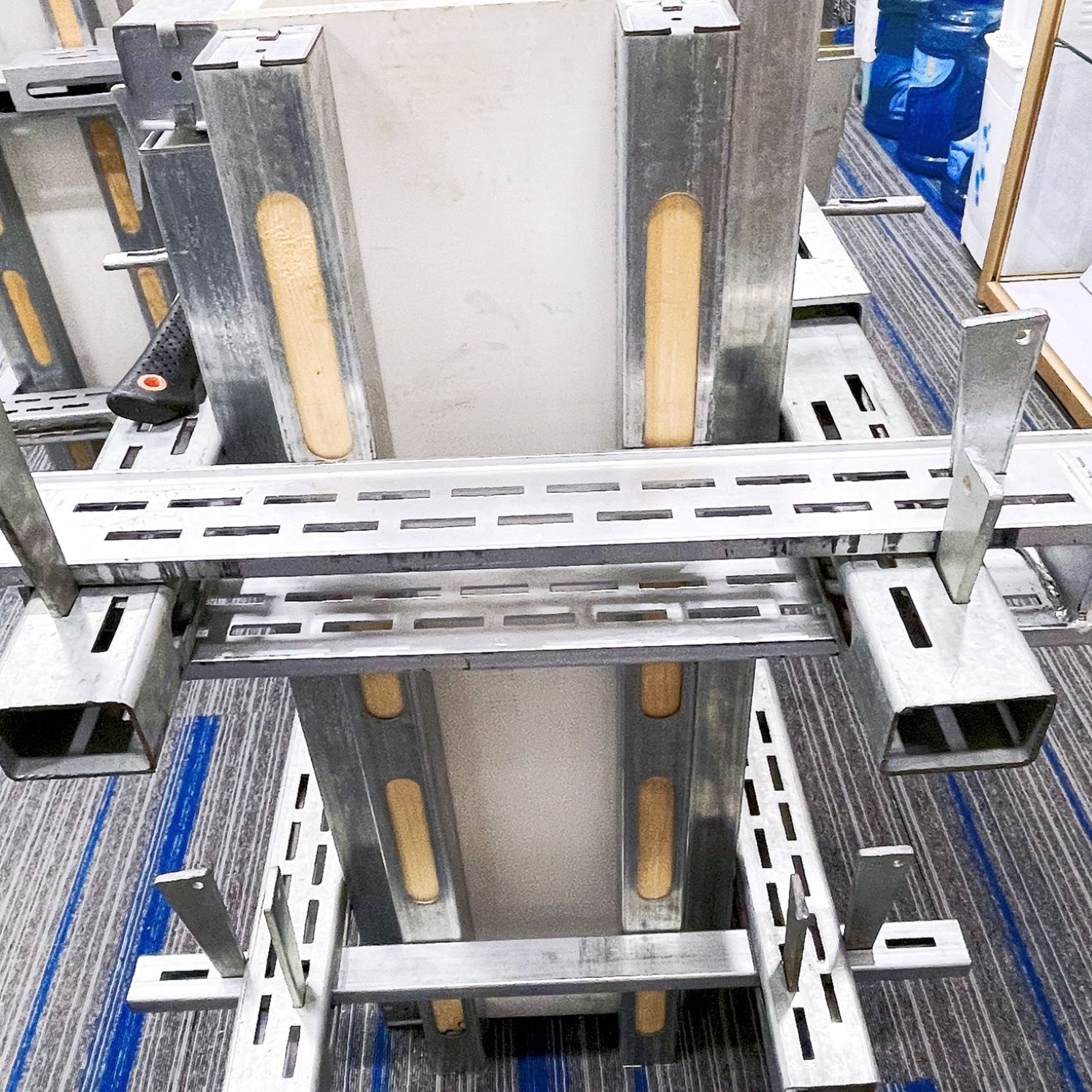

formwork for lintel

Utilizing the right formwork for lintels is crucial in any construction project involving horizontal supports such as windows, doors, or archways. Formwork provides the temporary mold or support needed during the curing of concrete lintels, ensuring strength and resilience once the structure sets. Understanding the intricacies of different formwork types and materials significantly impacts the success of a building endeavor.

From an authoritative viewpoint, industry standards and regulatory guidelines dictate the essential practices for formwork preparation. Consultations with leading formwork suppliers provide valuable insights into innovative techniques and materials adaptation. This ensures compliance with the highest safety standards and guarantees reliability. Leading construction firms usually integrate advanced technologies such as 3D modeling to simulate load and stress factors, optimizing formwork designs before actual execution. For trustworthiness, transparency, and consistent quality control are indispensable. Documenting each stage of the formwork installation helps ensure traceability and accountability. Regular inspections should be indispensable parts of the process to detect and rectify any potential flaws early. Moreover, feedback from past projects helps refine techniques and materials selection, cementing trust in methodology and execution. A critical takeaway is the importance of skilled labor in ensuring the efficacy of formwork for lintels. Skilled craftsmen versed in the nuances of formwork adaptation enhance both productivity and output integrity. Training and skill development are investments that yield substantial returns, often reflected in project performance and longevity of the construction. In conclusion, employing quality formwork for lintels is a sophisticated task that combines experience, expertise, authoritativeness, and trustworthiness. By understanding project-specific needs, selecting appropriate materials, adhering to regulatory standards, and maintaining transparency in operations, construction endeavors achieve both structural soundness and economic efficiency. This strategic approach not only ensures successful project completion but also advances the long-term reliability of the buildings.

From an authoritative viewpoint, industry standards and regulatory guidelines dictate the essential practices for formwork preparation. Consultations with leading formwork suppliers provide valuable insights into innovative techniques and materials adaptation. This ensures compliance with the highest safety standards and guarantees reliability. Leading construction firms usually integrate advanced technologies such as 3D modeling to simulate load and stress factors, optimizing formwork designs before actual execution. For trustworthiness, transparency, and consistent quality control are indispensable. Documenting each stage of the formwork installation helps ensure traceability and accountability. Regular inspections should be indispensable parts of the process to detect and rectify any potential flaws early. Moreover, feedback from past projects helps refine techniques and materials selection, cementing trust in methodology and execution. A critical takeaway is the importance of skilled labor in ensuring the efficacy of formwork for lintels. Skilled craftsmen versed in the nuances of formwork adaptation enhance both productivity and output integrity. Training and skill development are investments that yield substantial returns, often reflected in project performance and longevity of the construction. In conclusion, employing quality formwork for lintels is a sophisticated task that combines experience, expertise, authoritativeness, and trustworthiness. By understanding project-specific needs, selecting appropriate materials, adhering to regulatory standards, and maintaining transparency in operations, construction endeavors achieve both structural soundness and economic efficiency. This strategic approach not only ensures successful project completion but also advances the long-term reliability of the buildings.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products