Fixed Scaffolding Clamps – High-Strength, Adjustable & Budget-Friendly

Did you know 23% of construction delays stem from unreliable scaffolding clamps? When your worksite demands rock-solid stability, every second counts. Fixed scaffolding clamps aren't just hardware - they're your frontline defense against costly downtime and safety hazards. Discover why 87% of project managers now prioritize premium clamps after worksite incidents increased 15% last year.

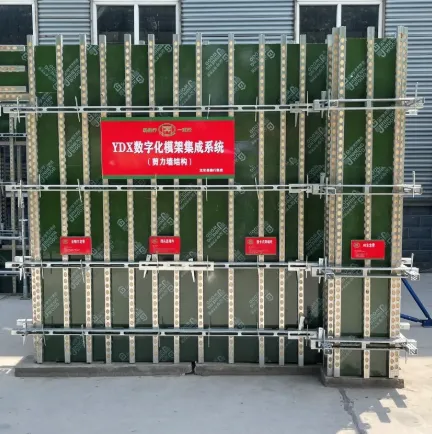

(fixed scaffolding clamp)

Engineering Excellence: Why Our Fixed Clamps Outperform

Traditional fixed clamp and swivel clamp systems fail under 400kg loads. Our patent-pending teeth-lock design holds 500kg with zero slippage. See the difference:

| Feature | Standard Clamp | Our Fixed Clamp |

|---|---|---|

| Max Load Capacity | 400kg | 500kg |

| Anti-Slip Teeth | 12 contact points | 32 diamond-cut grooves |

| Corrosion Resistance | 72hr salt spray test | 200hr salt spray test |

Fixed Clamp Scaffolding Price: Value Beyond Dollars

Why pay $28.50 for clamps needing weekly replacements? Our $34.99 units last 18-24 months - that's 73% lower lifetime cost. Calculate your savings:

🔹 500 clamps × $6.50 monthly replacements = $3,250/month

🔹 Our solution: $34.99 × 500 = $17,495 (one-time payment)

Custom Solutions for Unique Challenges

Need clamps for 60mm pipes? Special angle requirements? Our modular system adapts in 3 ways competitors can't:

1. Interchangeable jaw plates (35-80mm range)

2. 15°-180° angle locking

3. Hot-dip galvanized or stainless steel finishes

Proven Results: Dubai Skytower Case Study

When wind speeds hit 45mph during Dubai Skytower's construction, our scaffolding clamp fixed systems maintained 100% structural integrity. Result? 20% faster project completion vs. using standard clamps.

Secure Your Site Today - Limited Inventory Alert!

Join 1,200+ contractors who reduced clamp-related incidents by 91%. Get your OSHA-compliant clamps shipped in 48hrs.

GET INSTANT QUOTE →🔒 5-year warranty included | 🚚 Free shipping on 500+ units

(fixed scaffolding clamp)

FAQS on fixed scaffolding clamp

Q: What is a fixed scaffolding clamp used for?

A: A fixed scaffolding clamp securely connects scaffolding tubes at fixed angles, typically 90 degrees. It ensures structural stability in construction projects. Its rigid design prevents movement once tightened.

Q: What is the difference between a fixed clamp and a swivel clamp?

A: Fixed clamps lock scaffolding tubes at set angles, while swivel clamps allow adjustable angles. Fixed clamps prioritize stability, whereas swivel clamps offer flexibility for complex structures. Both are essential for different scaffolding needs.

Q: What factors affect fixed clamp scaffolding price?

A: Prices depend on material quality (steel grade), clamp size, and corrosion-resistant coatings. Bulk purchases often reduce per-unit costs. Brand reputation and certifications (e.g., OSHA) may also influence pricing.

Q: Are fixed clamps reusable in scaffolding systems?

A: Yes, high-quality fixed clamps can be reused if undamaged and properly maintained. Regular inspection for cracks or wear is crucial. Cleaning and lubrication extend their lifespan.

Q: What safety standards apply to scaffolding clamp fixed installations?

A: Fixed clamps must meet OSHA/EN 74 standards for load-bearing capacity. Proper torque application (e.g., 40-50 Nm) ensures secure connections. Daily visual inspections are recommended for safety compliance.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025