Durable Formwork Systems for Fast Construction

The Evolving Landscape of Construction: Current Formwork Industry Trends

The construction industry is undergoing a significant transformation, driven by demands for greater speed, sustainability, and safety. Formwork, as the critical temporary mold for concrete, is at the heart of this evolution. The global formwork market is projected to reach USD 6.8 billion by 2027, growing at a CAGR of 3.5%. This growth is fueled by several key trends that are reshaping how structures are built.

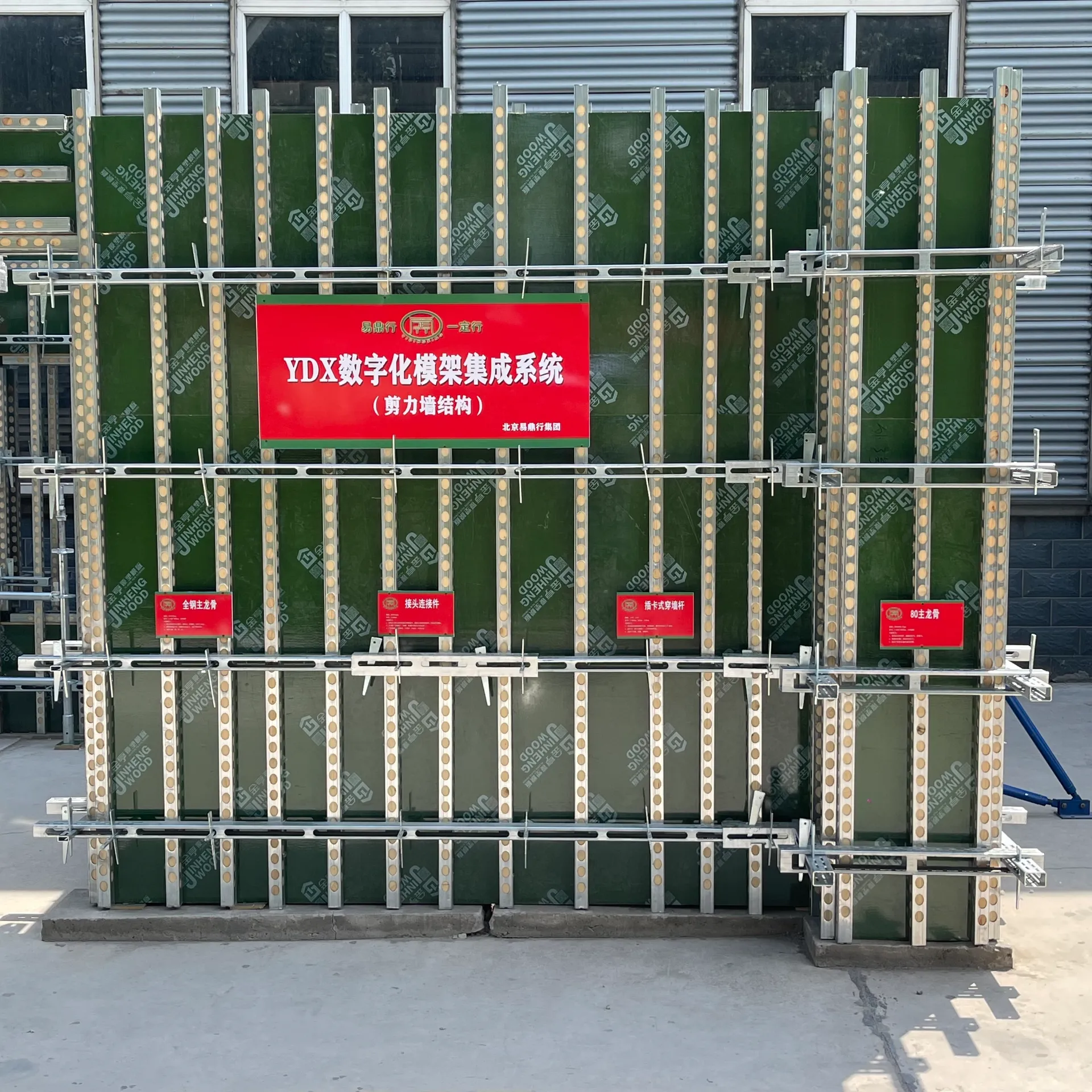

1. Rise of Modular & System Formwork

Prefabricated, reusable modular systems are replacing traditional timber formwork. This shift drastically reduces on-site waste, accelerates construction cycles, and improves the quality of the concrete finish. Systems like panel and climbing formwork are becoming standard for high-rise and large-scale infrastructure projects.

2. Emphasis on Lightweight Materials

Aluminum and advanced polymer composites are gaining traction. Their high strength-to-weight ratio makes handling easier, reduces labor costs, and minimizes crane time, directly impacting project timelines and budgets. An aluminum formwork panel can be up to 30% lighter than its steel counterpart with similar strength.

3. Integration with Digital Technologies (BIM)

Building Information Modeling (BIM) is revolutionizing formwork design. 3D models allow for precise planning, clash detection, and optimized material usage before a single component arrives on site. This digital-first approach, compliant with standards like ISO 19650, minimizes errors and enhances collaboration.

4. Focus on Sustainability and Reusability

With a global push for green building, the reusability of formwork systems is a key performance indicator. High-grade steel and aluminum systems can be reused hundreds of times, compared to just a handful for conventional plywood, significantly lowering the project's carbon footprint.

Deep Dive: Our Formwork Manufacturing Process & Technical Excellence

At FormworkReinforced, our commitment to quality is embedded in every stage of our manufacturing process. We combine cutting-edge technology with stringent quality control to produce Formwork systems that exceed industry standards. Our entire process is certified under ISO 9001:2015, ensuring consistency and reliability.

The Journey of a Formwork Panel: From Raw Material to Site-Ready

Understanding the manufacturing process provides insight into the durability and precision of our products. Here’s a simplified breakdown of how our premier steel formwork systems are created:

1. Material Selection

High-tensile steel (Q345B) or 6061-T6 aluminum alloy sourced from certified suppliers.

2. CNC Cutting & Shaping

Automated CNC laser cutters and presses for micron-level precision.

3. Robotic Welding

Ensures uniform weld strength and penetration, superior to manual methods.

4. Surface Treatment

Galvanization or electrostatic powder coating for corrosion resistance (exceeds ASTM B117 salt spray test).

5. Quality Assurance

Load testing, dimensional checks, and weld inspection for 100% compliance.

Key Technical Specifications & Advantages

- Material Grade: Steel (Q345B High-Strength Low-Alloy), Aluminum (6061-T6 Aerospace Grade). These materials are chosen for their optimal balance of strength, weight, and durability, conforming to international material standards.

- Concrete Pressure Capacity: Our standard wall formwork is designed to withstand fresh concrete pressures of up to 80 kN/m². Heavy-duty systems for mass concrete pours (dams, foundations) can be custom-engineered for pressures exceeding 120 kN/m², in line with ACI 347 guidelines.

- Service Life & Reusability: Our powder-coated steel formwork systems are rated for over 300 reuses, while our premium aluminum systems can achieve over 500 reuses with proper care, offering an exceptional return on investment.

- Surface Finish: Panels are available with high-quality phenolic-coated plywood or all-plastic facings, producing a smooth, F5-class concrete finish that often eliminates the need for remedial plastering.

- Applicable Industries: Versatile applications across high-rise residential & commercial construction, civil infrastructure (bridges, tunnels, metro stations), and industrial facilities (power plants, water treatment).

- Corrosion Resistance: Our hot-dip galvanizing process provides a thick, robust zinc coating that offers superior protection in harsh, coastal, or chemical environments, significantly extending the lifespan of the Formwork.

Data-Driven Comparison: Selecting the Right Formwork System

Choosing the right formwork system is a critical decision that impacts project cost, speed, and quality. A data-driven approach is essential. The table below compares the most common types of formwork systems across key performance metrics.

| Parameter | Aluminum Formwork | Steel Formwork | Timber/Plywood Formwork | Plastic Formwork |

|---|---|---|---|---|

| Weight (kg/m²) | ~18-25 | ~40-60 | ~20-30 | ~15-20 |

| Reusability (Cycles) | 300 - 500+ | 200 - 300+ | 5 - 15 | 50 - 100+ |

| Initial Cost | High | Medium-High | Low | Medium |

| Labor Intensity | Low (No Crane Required) | High (Crane Dependent) | High (Skilled Labor) | Very Low |

| Pouring Speed | Fast (Monolithic Pouring) | Medium | Slow | Fast |

| Concrete Finish | Excellent (F5) | Very Good (F4/F5) | Fair to Good (F2-F4) | Excellent (F5) |

| Sustainability | High (Recyclable) | High (Recyclable) | Low (High Waste) | Medium (Recyclable) |

Visualizing Performance Metrics

Charts help to visualize the distinct advantages of different systems, aiding in a more intuitive decision-making process.

Key Performance Indicator Comparison

Average Reusability Cycles

Global Formwork Market Share by Material (Approx.)

- Steel (45%)

- Timber & Plywood (30%)

- Aluminum (15%)

- Others (Plastic, etc.) (10%)

Market distribution based on material usage.

From Blueprint to Reality: Custom Formwork Solutions & Application Cases

Standard solutions don't always fit complex architectural visions. Our core strength lies in providing bespoke Formwork solutions. Our engineering team works closely with clients from the initial design phase, utilizing BIM and structural analysis software to develop systems tailored for unique geometries, heavy loads, and challenging site conditions.

Case Study: The "Skyline Tower" High-Rise Project

- Client: Apex Global Construction

- Project: 50-story mixed-use skyscraper with curved facades and complex core walls.

- Challenge: The client required a solution to accelerate the floor-to-floor cycle time to under 6 days, while ensuring a premium architectural finish on the exposed concrete surfaces. The curved geometry made traditional formwork impractical and costly.

- Our Solution: We designed a hybrid system combining:

- A self-climbing core formwork system for the central elevator shafts.

- Custom-fabricated, curved aluminum panel formwork for the unique building facade.

- Lightweight, crane-independent slab formwork for typical floors, allowing for parallel work streams.

- Outcome (Experience & Trust):

- Achieved a 5-day floor cycle, reducing the structural construction timeline by over 20%.

- The precision-engineered aluminum forms delivered a flawless concrete finish, saving an estimated $500,000 in plastering and rendering costs.

- Our on-site technical support and just-in-time delivery schedule were cited by the client as "critical to the project's success." Apex Global Construction has since partnered with us on three subsequent projects, a testament to our performance and reliability.

Frequently Asked Questions (FAQ) about Formwork

Conventional formwork typically refers to traditional timber and plywood systems that are custom-built on-site for a specific pour and then largely discarded. It is labor-intensive and generates significant waste. Modular formwork, on the other hand, consists of prefabricated, engineered panels and components (made of steel, aluminum, or plastic) that can be quickly assembled, disassembled, and reused hundreds of times across different projects. It prioritizes speed, efficiency, and sustainability.

The maximum lateral pressure exerted by fresh concrete is a critical calculation governed by standards like ACI 347R-14. Key factors include: the rate of pour (m/hr), concrete temperature, concrete density, slump, and the type of cement and admixtures used. Our engineers use specialized software to model these variables and ensure the selected formwork system, including tie spacing and waler strength, can safely withstand the calculated maximum pressure with a significant safety factor.

Stripping time (or striking time) is the period before formwork can be safely removed. It depends primarily on the concrete achieving sufficient compressive strength to support its own weight and any imposed loads. This is influenced by:

- Concrete mix design (e.g., high early strength mix).

- Ambient temperature (curing is faster in warmer weather).

- The type of structural element (vertical forms on walls can be removed sooner than horizontal forms supporting slabs).

- Admixtures used.

Stripping times are strictly defined by project specifications and structural engineering requirements, often verified by on-site cube/cylinder tests.

The release agent is a crucial but often overlooked component. A high-quality, non-staining, chemically reactive release agent does two things: 1) It creates a barrier to prevent the concrete from bonding to the form face, ensuring a clean, easy strip and a smooth surface finish. 2) It protects the formwork face (especially plywood) from moisture and alkaline attack, significantly extending its service life. Using the wrong agent (like waste motor oil) can stain the concrete, hinder stripping, and degrade the form panels rapidly.

In North America, the primary guide is ACI 347, "Guide to Formwork for Concrete." In Europe, Eurocode 2 (EN 1992-1-1) provides design rules for concrete structures, which implicitly govern formwork requirements. Additionally, safety standards like OSHA 1926 Subpart Q in the US are paramount. These standards dictate design loads, safety factors, requirements for shoring and reshoring, inspection protocols, and safe erection/dismantling procedures to ensure structural integrity and worker safety.

Absolutely. Our panelized wall formwork systems are designed for full compatibility with leading hydraulic self-climbing systems. We provide the necessary connection points and structural calculations to ensure a seamless and safe integration. This combination is the industry standard for constructing cores of high-rise buildings, allowing the formwork to "climb" the structure autonomously without relying on a crane, dramatically accelerating the construction schedule.

Proper maintenance is key to maximizing reusability. For both systems, the primary routine after each use is: "Clean, Repair, and Coat."

- Cleaning: Immediately after stripping, scrape off all concrete residue using non-aggressive tools (e.g., plastic or wooden scrapers). High-pressure water jets are also effective.

- Repair: Inspect for damage. For steel, minor dents can be hammered out and welds checked. For aluminum, which is softer, damage requires more careful assessment. Damaged tie-holes or panel edges should be repaired.

- Coat: Re-apply a quality release agent before the next use. For steel forms, any scratches in the powder coating should be touched up to prevent rust.

Our Commitment to You: Trustworthiness and Support

Our relationship with clients extends far beyond the sale. We build partnerships based on trust, transparency, and unwavering support.

Delivery & Logistics

We offer a transparent delivery schedule, with standard systems shipping within 2-3 weeks. Custom solutions have a clear, project-specific timeline established upfront. Our logistics team coordinates just-in-time delivery to your site to minimize storage needs.

Warranty & Quality Guarantee

All our Formwork systems come with a comprehensive manufacturer's warranty covering defects in materials and workmanship. We guarantee our products meet or exceed the technical specifications and load capacities quoted.

Expert Customer Support

From initial consultation to on-site training and troubleshooting, our team of experienced engineers and technicians is available to ensure you get the most out of your formwork investment. We provide detailed assembly drawings, safety manuals, and on-site supervision upon request.

Authoritative References & Further Reading

To deepen your understanding and validate the principles discussed, we recommend consulting these authoritative industry resources:

- ACI Committee 347, "Guide to Formwork for Concrete (ACI 347R-14)": "The design and engineering of formwork must consider not only the fluid pressure of concrete but also the construction live loads, the rate of placement, and environmental factors to ensure safety and performance." - An essential standard for any professional in the field. Learn more at concrete.org.

- Construction Industry Research and Information Association (CIRIA), "Report C762 - Formwork and falsework: guidance and good practice": This report emphasizes the importance of risk management and temporary works coordination. It notes, "A significant proportion of construction failures are attributable to temporary works... rigorous planning and inspection of formwork are non-negotiable." Explore at ciria.org.

- ForConstructionPros.com Forum Discussion on Formwork Trends: A user on a popular industry forum notes, "We switched to an aluminum modular system two years ago. The initial investment was steep, but we broke even on the fourth project. The speed and finish quality are game-changers. We'll never go back to stick-building forms." This reflects direct industry experience. Read discussions at ForConstructionPros.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025