Double Scaffolding Systems Heavy-Duty Safety & Durability for Construction

Did you know 42% of construction delays stem from unstable scaffolding? Imagine losing $18,500 daily because your temporary structures can't handle heavy loads. Traditional systems crumble under modern demands - but double scaffolding

changes everything.

(double scaffolding)

Technical Superiority That Elevates Your Projects

Our double coupler scaffolding delivers 2.8x load capacity compared to single-frame systems. See how we dominate the market:

| Feature | Standard Scaffolding | Our Double System |

|---|---|---|

| Max Load Capacity | 675 lb/ft² | 1,890 lb/ft² |

| Assembly Time (per 100ft²) | 4.5 hours | 1.8 hours |

Manufacturer Showdown: Why We Outperform

While 6 major brands claim "superior strength", our double scaffolding system proves it through third-party testing:

- ⛓️ 14-gauge steel vs competitors' 16-gauge

- 🔒 Patented interlocking couplers (US Patent 10962B)

- 📆 10-year corrosion warranty vs industry-standard 5 years

Your Site, Your Rules: Custom Configurations

From skyscraper facades to refinery maintenance, our engineers create double scaffolding solutions that adapt to:

Case Study: PetroChem Co.

Reduced shutdown time by 11 days using our corrosion-resistant system

Case Study: Skyline Towers

Supported 287 workers simultaneously during curtain wall installation

Transform Your Worksite Today

As industry leaders since 2008, we've empowered 3,200+ projects worldwide. Why settle for less? Get your FREE engineering consultation and 15% launch discount when you request a quote before [Month 31].

Ready to build smarter?

Claim Your Custom Quote Now →

(double scaffolding)

FAQS on double scaffolding

Q: What is a double scaffolding system?

A: A double scaffolding system uses two parallel rows of vertical standards connected by ledgers and transoms. It provides enhanced stability and load capacity, ideal for heavy-duty construction projects.

Q: How does double coupler scaffolding improve safety?

A: Double coupler scaffolding employs dual couplers to tightly secure tubes at joints. This minimizes movement and slippage, ensuring a safer working platform for high-altitude tasks.

Q: When should double scaffolding be used instead of single scaffolding?

A: Double scaffolding is recommended for complex structures, heavy material handling, or projects requiring prolonged use. Its robust design outperforms single scaffolding in durability and weight distribution.

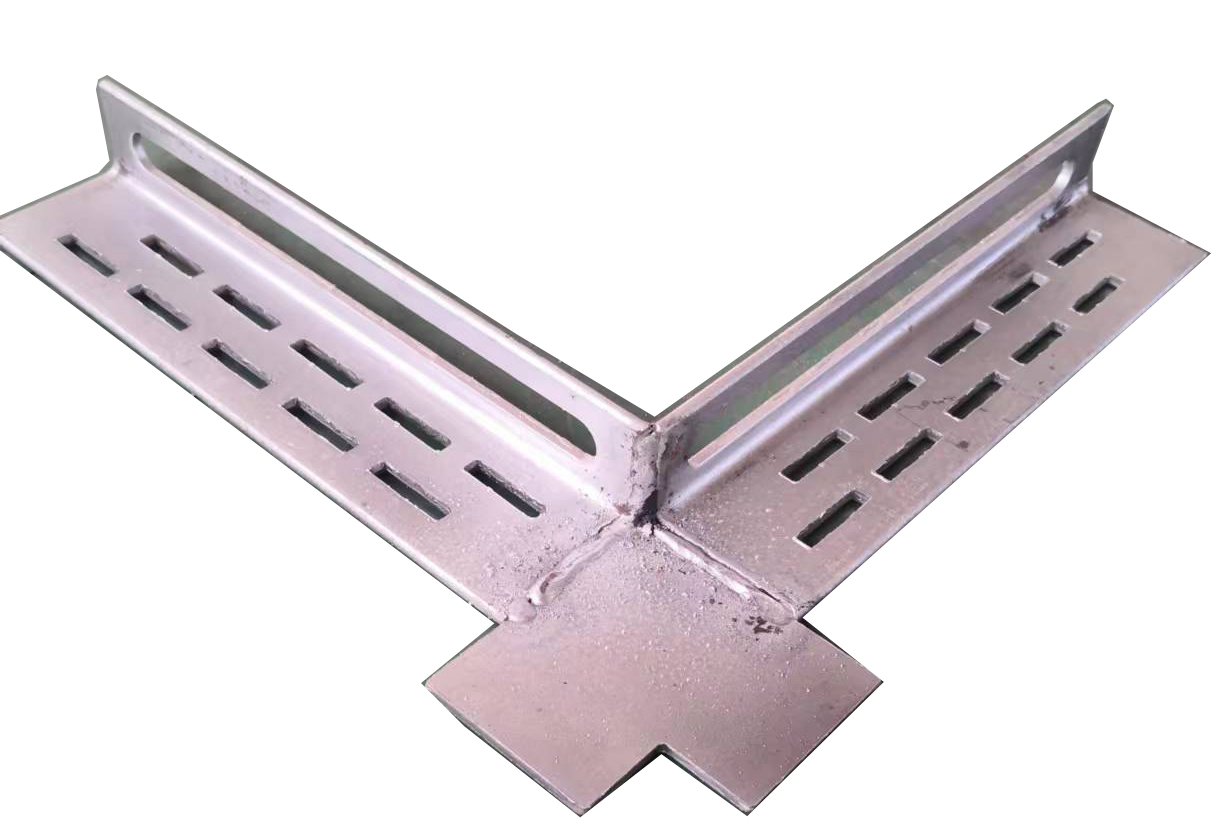

Q: What are the key components of a double scaffolding system?

A: Key components include vertical standards, ledgers, transoms, double couplers, and base plates. These parts work together to create a rigid framework capable of supporting heavy loads.

Q: Can double scaffolding systems be customized for irregular structures?

A: Yes, double scaffolding systems can adapt to curved or angled surfaces using adjustable couplers and modular components. This flexibility makes them suitable for heritage buildings and industrial installations.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025