Innovative Solutions for Securely Connecting Aluma Beams with Reliable Clamp Designs

Understanding Aluma Beam Clamps Essential Tools in Construction and Engineering

In the world of construction and engineering, the significance of reliable equipment cannot be overstated. Among these vital tools are Aluma beam clamps, which play an essential role in supporting structures and ensuring safety during various applications. This article explores the functionality, advantages, and applications of Aluma beam clamps, making a case for their critical importance in the construction industry.

What are Aluma Beam Clamps?

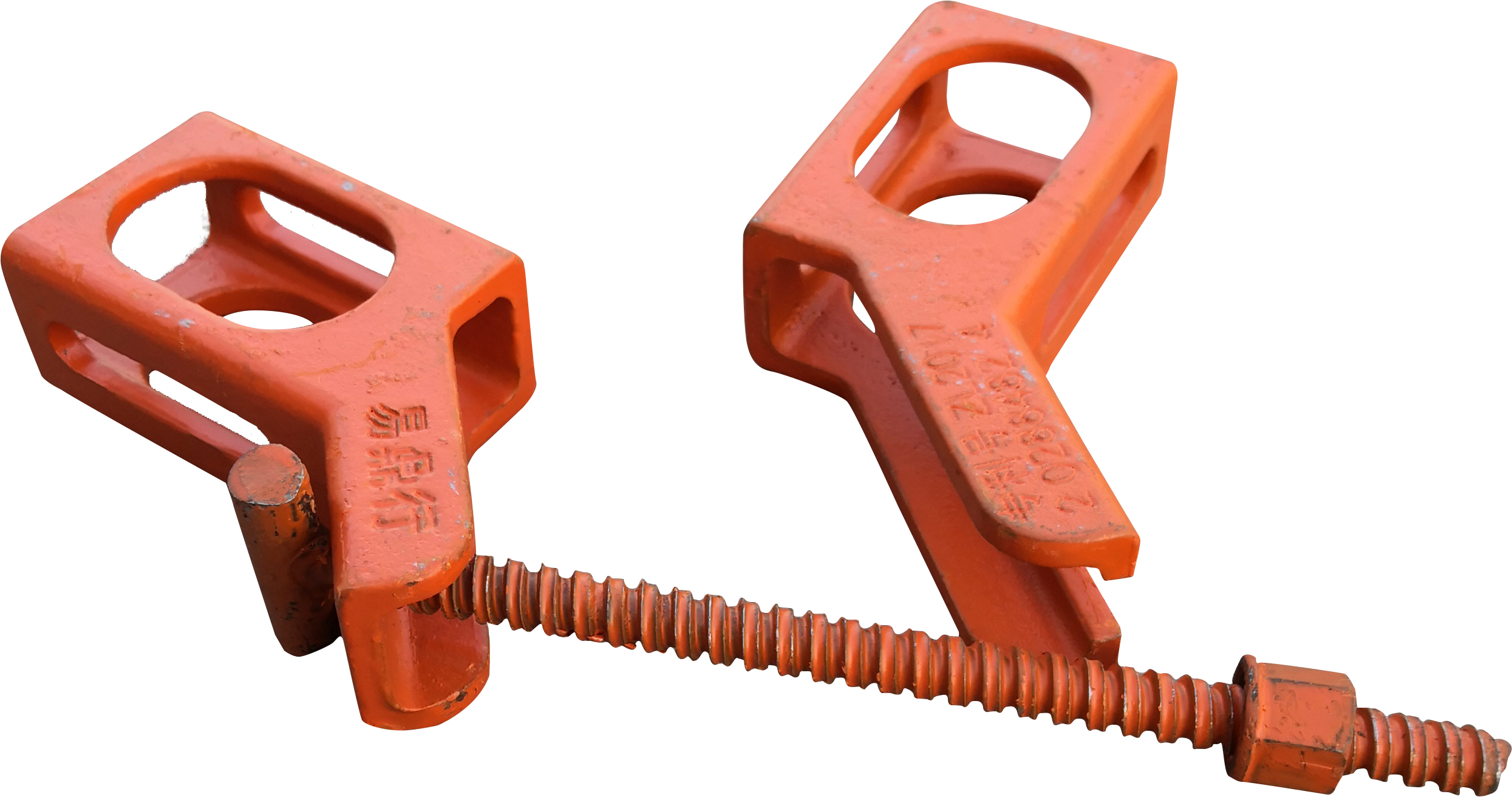

Aluma beam clamps are specialized clamps designed to secure aluminum beams together or to other structural components. Made from high-strength aluminum alloys, these clamps are lightweight yet incredibly sturdy, making them ideal for temporary or permanent installations. They come in various designs, including single and double clamps, depending on the load requirements and the specific application.

How Do Aluma Beam Clamps Work?

The primary function of an Aluma beam clamp is to provide a strong grip on the beams, thereby ensuring stability and alignment. They typically feature easy-to-use designs that allow for quick setup and adjustments. Each clamp is equipped with a tightening mechanism, usually a screw or a latch, that enables the user to secure the clamp tightly around the beam. This secure grip prevents any shifting or movement during construction, which is vital for maintaining the integrity of the structure being built.

Advantages of Aluma Beam Clamps

1. Lightweight and Portable One of the standout features of Aluma beam clamps is their lightweight construction. This property facilitates easy handling and transportation, which is particularly important on crowded job sites where space can be limited.

aluma beam clamps

2. Corrosion Resistance Aluma beam clamps are often anodized or treated to resist corrosion, making them suitable for various environments, including those exposed to moisture or chemicals. This quality extends their lifespan and reduces the need for frequent replacements.

3. Versatile Applications These clamps are highly versatile. They can be used in scaffolding, rigging, and other applications where aluminum beams require stability. Their adaptable nature makes them a preferred choice in different sectors, including construction, entertainment (for staging), and industrial settings.

4. Ease of Installation With their user-friendly design, Aluma beam clamps can often be installed without specialized tools. This ease of use makes them accessible even to those who may not have extensive experience in rigging or construction.

5. Enhanced Safety Safety is paramount in any construction project. The secure grip of Aluma beam clamps minimizes the risk of accidents caused by falling or shifting beams. Additionally, the reflective surface of aluminum can increase visibility, promoting a safer working environment.

Applications of Aluma Beam Clamps

Aluma beam clamps find utility across a wide range of applications. In the construction industry, they are commonly used to support scaffolding systems, allowing workers to operate safely at heights. In the entertainment sector, they are utilized to secure lighting rigs and sound equipment during concerts and events. Furthermore, these clamps are employed in industrial settings for hanging pipes, ducts, or other equipment, showcasing their adaptability across various fields.

Conclusion

In summary, Aluma beam clamps are indispensable tools in modern construction and engineering. Their lightweight design, corrosion resistance, versatility, ease of installation, and focus on safety make them a go-to choice for professionals in various industries. As projects continue to grow in complexity and scale, the demand for reliable equipment like Aluma beam clamps will only increase, cementing their role as essential components in ensuring structural stability and safety. Investing in quality clamps is not just a practical decision; it is a commitment to excellence in construction practices.

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025