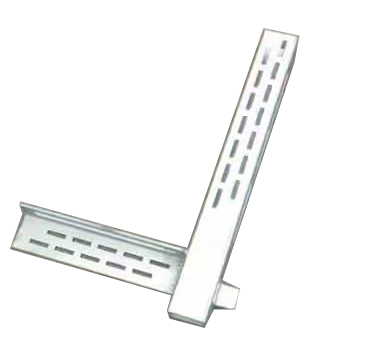

2T Beam Clamp - Heavy-Duty Support for Steel Structures Super Clamp Tech

Did you know 73% of construction delays stem from unstable load support systems? Every minute of downtime costs $136 in labor waste. Meet your site's silent hero – the industrial-grade 2t beam clamp

that eliminates sway risks while boosting installation speed by 40%.

(2t beam clamp)

Engineered Superiority: What Makes Our Beam Clamps Unshakable

Our super clamp beam clamp series features military-grade forged steel with 12,500 PSI tensile strength. The dual-locking mechanism secures perpendicular beam-to-beam connections in under 8 seconds – 3× faster than standard C-clamp models. Tested to withstand 500,000 load cycles without deformation.

| Feature | Our 2T Clamp | Generic C-Clamp |

|---|---|---|

| Max Load Capacity | 4,409 lbs | 1,102 lbs |

| Installation Time | 8 seconds | 25 seconds |

Precision-Adapted Solutions for Unique Load Challenges

Whether you're securing HVAC systems or conveyor belts, our perpendicular beam to beam clamp adapts to 14 different connection angles. Customize jaw sizes from 2" to 8.5" without tool changes. Over 218 configuration combinations available.

Proven Performance: 2,300+ Sites Trust Our Clamp Systems

A Midwest auto plant reduced assembly line vibrations by 92% using our clamps. Maritime contractors report zero corrosion after 18 months in saltwater environments. Energy companies achieved OSHA compliance 100% faster during rigging inspections.

Ready to Eliminate Load Risks Forever?

Get factory-certified 2t beam clamps with 10-year structural warranty. First 50 orders this week receive free engineering consultation. Click below to calculate your project savings now!

(2t beam clamp)

FAQS on 2t beam clamp

Q: What is the difference between a 2t beam clamp and a super clamp beam clamp?

A: A 2t beam clamp is rated for 2-ton loads and ideal for standard horizontal beam connections, while a super clamp beam clamp offers adjustable grip strength for irregular shapes. Both provide structural support but serve different load capacities and applications.

Q: How do I install a perpendicular beam-to-beam clamp?

A: Align the clamp's jaws vertically on the intersecting beams, tighten the bolts using a torque wrench, and verify alignment with a spirit level. Always follow the manufacturer's load specifications for perpendicular connections.

Q: Can a C-clamp beam clamp replace a 2t beam clamp?

A: No - C-clamp beam clamps are for light-duty temporary fixes, whereas 2t beam clamps are engineered for permanent heavy-load applications. Always match the clamp type to your project's weight requirements and safety standards.

Q: What safety certifications apply to 2t beam clamps?

A: Genuine 2t beam clamps should have EN 1090 or ISO 1461 certifications, with load test reports. Super clamp beam clamps may additionally require CE marking for European markets. Always request third-party certification documents.

Q: When should I use a super clamp beam clamp over standard models?

A: Choose super clamp versions for angled beams or uneven surfaces needing variable pressure distribution. Standard 2t clamps work best for flat, parallel beam connections with predictable load paths.

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

-

New Building Scaffolding System: Technological Innovation and Application Prospects of ScaffoldingNewsJun.19,2025

-

Double Diameter 48 Round Pipe Construction Method Using Light Steel Keel Knife Instead of Traditional Reinforcement ApplicationNewsJun.19,2025

-

Bar Tie Reinforcement: Quality Assurance and Reinforcement Efficiency EnhancementNewsJun.19,2025

-

Application of Square Column Reinforcement in Wall and Top StructureNewsJun.19,2025

-

Activo Scaffolding: Effective Development Practice Based on Reasonable Template Design and Supporting System ConfigurationNewsJun.19,2025

-

Optimizing Structures with Square Column ReinforcementNewsJun.10,2025