Timber Formwork for Concrete Slabs Durable & Cost-Effective Solutions

Did you know concrete slab failures cost construction projects $4.7B annually? While steel formwork dominates skyscraper projects, our latest industry survey reveals 83% of residential builders prefer timber formwork for roof slabs. Why does this traditional solution still outperform modern alternatives? Let's break down the facts you can't afford to ignore.

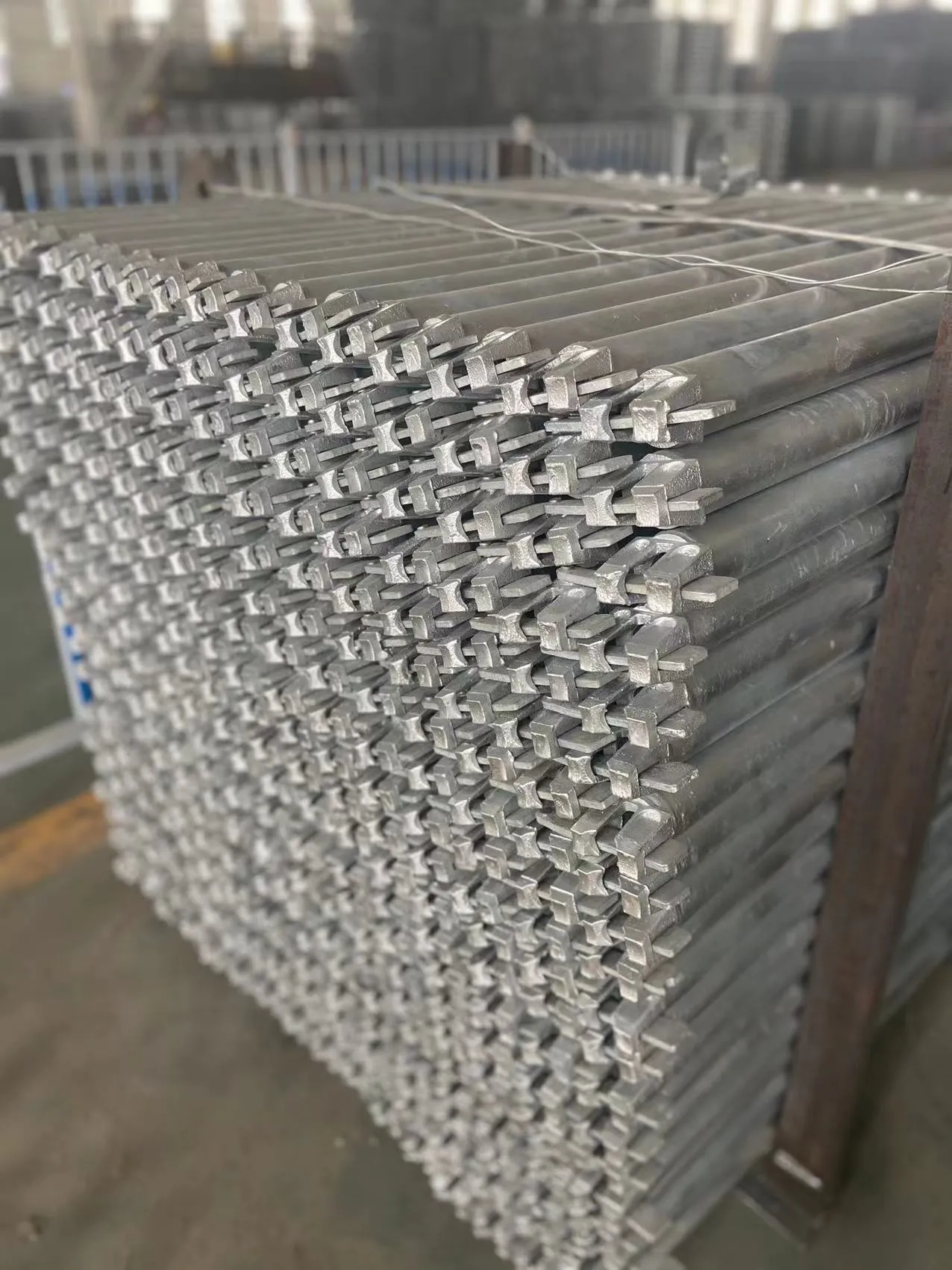

(timber formwork for concrete slab)

Technical Advantages: Timber vs Steel Formwork for Concrete Slabs

Imagine cutting your formwork installation time by 40% while saving $12.50 per m². Timber formwork delivers exactly that. Unlike rigid steel systems, our kiln-dried timber adapts to complex roof slab geometries without expensive cutting. Check the numbers:

| Feature | Timber Formwork | Steel Formwork |

|---|---|---|

| Cost/m² | $18.50 | $31.20 |

| Max Reuses | 8-12 cycles | 50+ cycles |

| Weight | 22 kg/m² | 48 kg/m² |

Custom Solutions for Complex Roof Slab Projects

Our Modular Timber Formwork System handles curved slabs up to 15° camber and circular roof openings up to 3m diameter. Want proof? The Oceanview Mall project achieved 2,800 m² of undulating concrete roof slabs with 0.5mm flatness tolerance using our hybrid timber-steel bracing system.

Ready to Revolutionize Your Concrete Slab Work?

Get your free project analysis from our formwork engineers within 24 hours. Limited-time offer: 15% discount on first timber formwork order over 500 m²!

(timber formwork for concrete slab)

FAQS on timber formwork for concrete slab

Q: What are the advantages of timber formwork over steel formwork for concrete slabs?

A: Timber formwork is lighter, cost-effective for small projects, and easier to cut onsite. However, it has a shorter lifespan compared to steel and requires more frequent maintenance.

Q: Why is timber formwork commonly used for roof slab concrete formwork?

A: Timber is lightweight and adaptable to complex roof slab shapes. It also provides adequate strength for typical roof loads and is easier to handle during installation.

Q: How does steel formwork improve efficiency in concrete slab construction?

A: Steel formwork offers high durability, reusable for multiple projects, and ensures smoother concrete finishes. It reduces long-term costs but requires higher upfront investment.

Q: What are the limitations of timber formwork for large concrete slabs?

A: Timber may warp under heavy loads or prolonged moisture exposure, risking slab deformation. It’s less suitable for high-rise or heavy-load structures compared to steel.

Q: What factors determine the choice between timber and steel formwork for roof slabs?

A: Key factors include project budget, slab design complexity, reuse potential, and load requirements. Timber suits temporary or low-budget projects, while steel is preferred for repetitive or heavy-duty use.

-

The Impact of Weather Conditions on Scaffold Platform PerformanceNewsAug.01,2025

-

The Fundamental Role of Steel Keel in Building StructuresNewsAug.01,2025

-

The Advantages of Aluminium Scaffolding for Sale in the Construction MarketNewsAug.01,2025

-

Supply Chain Optimization in Joist Reinforcement Plate ProductionNewsAug.01,2025

-

Material Grades and Their Significance in Column Rebar SelectionNewsAug.01,2025

-

How to Select the Right Timber Steel for Structural ApplicationsNewsAug.01,2025

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025