2월 . 01, 2025 02:10

Back to list

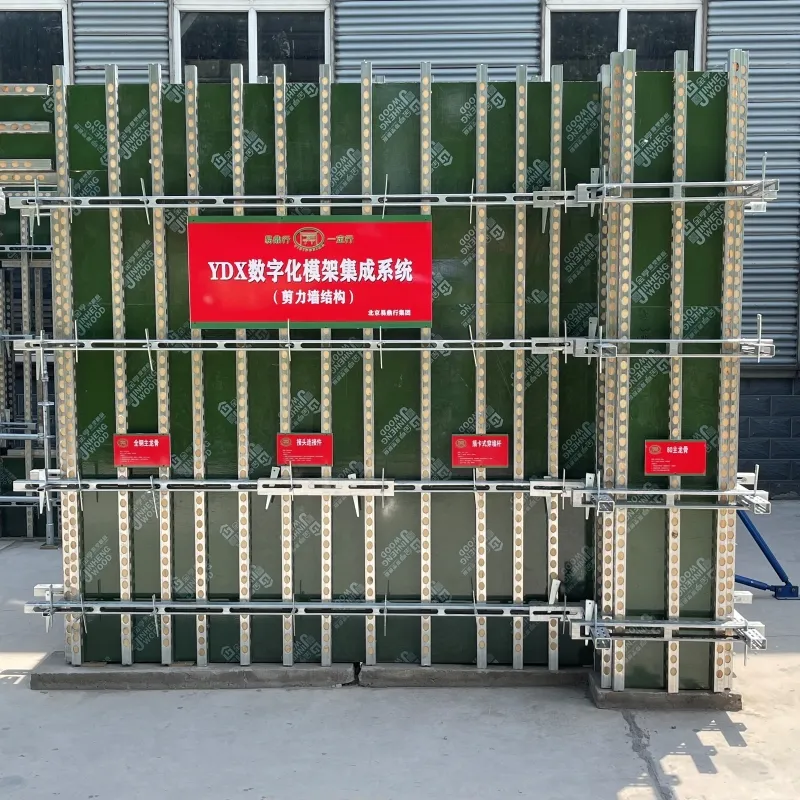

reinforced concrete formwork

Reinforced concrete formwork has become an integral part of modern construction, combining durability with flexibility to meet the demands of both simple and complex building projects. This integration significantly contributes to cost-effectiveness and provides a strong foundation for varied architectural visions.

On the other hand, more contemporary systems like steel, aluminum, or plastic formwork provide quicker assembly and a cleaner finished product. These materials deliver the added benefit of being reusable, reducing both waste and costs in the long term. Steel formwork, in particular, offers exceptional durability and strength, making it an ideal choice for large-scale projects. Aluminum, while lighter, maintains strength and is easier to handle on-site, further expediting construction timelines. For those seeking an efficient and economic solution, modular formwork presents an attractive option, particularly in the standardized construction of residential or commercial units. Modular systems rely on pre-engineered panels that can quickly form complete walls, floors, and ceilings in a fraction of the time, reducing labor costs and time delays significantly. The installation and safety practices involved in working with reinforced concrete formwork continually evolve to better adhere to construction industry standards. Companies dedicated to this field employ qualified engineers to ensure precision in designing the formwork systems. This attention to detail before a single ounce of concrete is poured highlights the importance of expertise within the formwork industry. Well-executed formwork not only meets the safety standards but enhances structural integrity and optimizes resource use. In essence, trust in the capabilities of reinforced concrete formwork has been built over decades of successful implementation across varied construction domains. By marrying simple ingredients with advanced engineering, reinforced formwork has proven to be not just a reliable framework for concrete but also a critical partner in modern architectural development. As the construction industry continues to innovate, the adaptability and efficiency of reinforced concrete formwork assure its status as a cornerstone of contemporary and future projects. Ultimately, efficacy in the use of reinforced concrete formwork lies in the intersection of experience, expertise, authoritativeness, and trustworthiness. Architects, engineers, contractors, and builders collectively appreciate the material's contribution to building designs that prioritize safety, functionality, and beauty. As the evolving landscape of construction introduces new design challenges, reinforced concrete formwork will remain indispensable, driving the industry forward with durable, flexible, and sustainable solutions.

On the other hand, more contemporary systems like steel, aluminum, or plastic formwork provide quicker assembly and a cleaner finished product. These materials deliver the added benefit of being reusable, reducing both waste and costs in the long term. Steel formwork, in particular, offers exceptional durability and strength, making it an ideal choice for large-scale projects. Aluminum, while lighter, maintains strength and is easier to handle on-site, further expediting construction timelines. For those seeking an efficient and economic solution, modular formwork presents an attractive option, particularly in the standardized construction of residential or commercial units. Modular systems rely on pre-engineered panels that can quickly form complete walls, floors, and ceilings in a fraction of the time, reducing labor costs and time delays significantly. The installation and safety practices involved in working with reinforced concrete formwork continually evolve to better adhere to construction industry standards. Companies dedicated to this field employ qualified engineers to ensure precision in designing the formwork systems. This attention to detail before a single ounce of concrete is poured highlights the importance of expertise within the formwork industry. Well-executed formwork not only meets the safety standards but enhances structural integrity and optimizes resource use. In essence, trust in the capabilities of reinforced concrete formwork has been built over decades of successful implementation across varied construction domains. By marrying simple ingredients with advanced engineering, reinforced formwork has proven to be not just a reliable framework for concrete but also a critical partner in modern architectural development. As the construction industry continues to innovate, the adaptability and efficiency of reinforced concrete formwork assure its status as a cornerstone of contemporary and future projects. Ultimately, efficacy in the use of reinforced concrete formwork lies in the intersection of experience, expertise, authoritativeness, and trustworthiness. Architects, engineers, contractors, and builders collectively appreciate the material's contribution to building designs that prioritize safety, functionality, and beauty. As the evolving landscape of construction introduces new design challenges, reinforced concrete formwork will remain indispensable, driving the industry forward with durable, flexible, and sustainable solutions.

Share

Latest news

-

The Importance of Reinforcement Bar in ConstructionNewsJul.11,2025

-

The Durability of Timber Steel FurnitureNewsJul.11,2025

-

How to Assemble Fixed Clamp Scaffolding SafelyNewsJul.11,2025

-

Essential Column Rebar Specifications for High-Rise BuildingsNewsJul.11,2025

-

Common Applications of Steel Keels in ConstructionNewsJul.11,2025

-

Benefits of Using Aluminum Scaffolding Ladders Over SteelNewsJul.11,2025

-

Stainless Steel Keel: Analysis of the Triple Advantages of Rigidity, Stability, and LightweightNewsJun.19,2025

Related Products